• Install the prescribed fuse on each cable

• Parallel supply cable (2 x 3 PE - configuration (2)):

• Add 10 % to the total compressor current (I

tot

Pack or I

tot

FF from the tables) and divide by 2

• Multiply the ampacity of the cables with 0.8 (see table A.52.17 (52-E1))

• Install fuses of half the size of the recommended maximum fuse size on each cable.

• When using 2 x 3 PE as in (3):

• Add 10 % to the total compressor current (I

tot

Pack or I

tot

FF from the tables) and divide by √3

• Multiply the ampacity of the cables with 0.8 (see table A.52.17 (52-E1))

• Fuse size: the recommended maximum fuse size divided by √3 on each cable.

• Size of the PE cable:

• For supply cables up to 35 mm²: same size as supply cables

• For supply cables larger than 35 mm²: half the size of the supply wires

Always check the voltage drop over the cable (less than 5 % of the nominal voltage is recommended).

Example:

I

tot

= 89 A, maximum ambient temperature is 45 °C, recommended fuse = 100 A

• Single supply cables (3 PE - configuration (1)):

• I = 89 A + 10 % = 89 x 1.1 = 97.9 A

• The table for B2 and ambient temperature = 45 ° C allows a maximum current of 93 A for a 50 mm²

cable. For a cable of 70 mm², the maximum allowed current is 118 A, which is sufficient. Therefore,

use a 3 x 70 mm² + 35 mm² cable.

If method C is used, 50 mm² is suffficient. (35 mm² for method F) => cable 3 x 50 mm² + 25 mm².

• Parallel supply cable (2 x 3 PE - configuration (2)):

• I = (89 A + 10 %)/2 = (89 x 1.1)/2 = 49 A

• For a cable of 25 mm², B2 at 45 °C, the maximum current is 63 A x 0.8 = 50.4 A. So 2 parallel cables

of 3 x 25 mm² + 25 mm² are sufficient.

• Install 50 A fuses on each cable instead of 100 A.

Fuse calculations for IEC

are done according to 60364-4-43 electrical installations of buildings, part 4:

protection for safety- section 43: protection against overcurrent. Fuse sizes are calculated in order to protect

the cable against short circuit. Fuse type aM is recommended but gG/gL is also allowed.

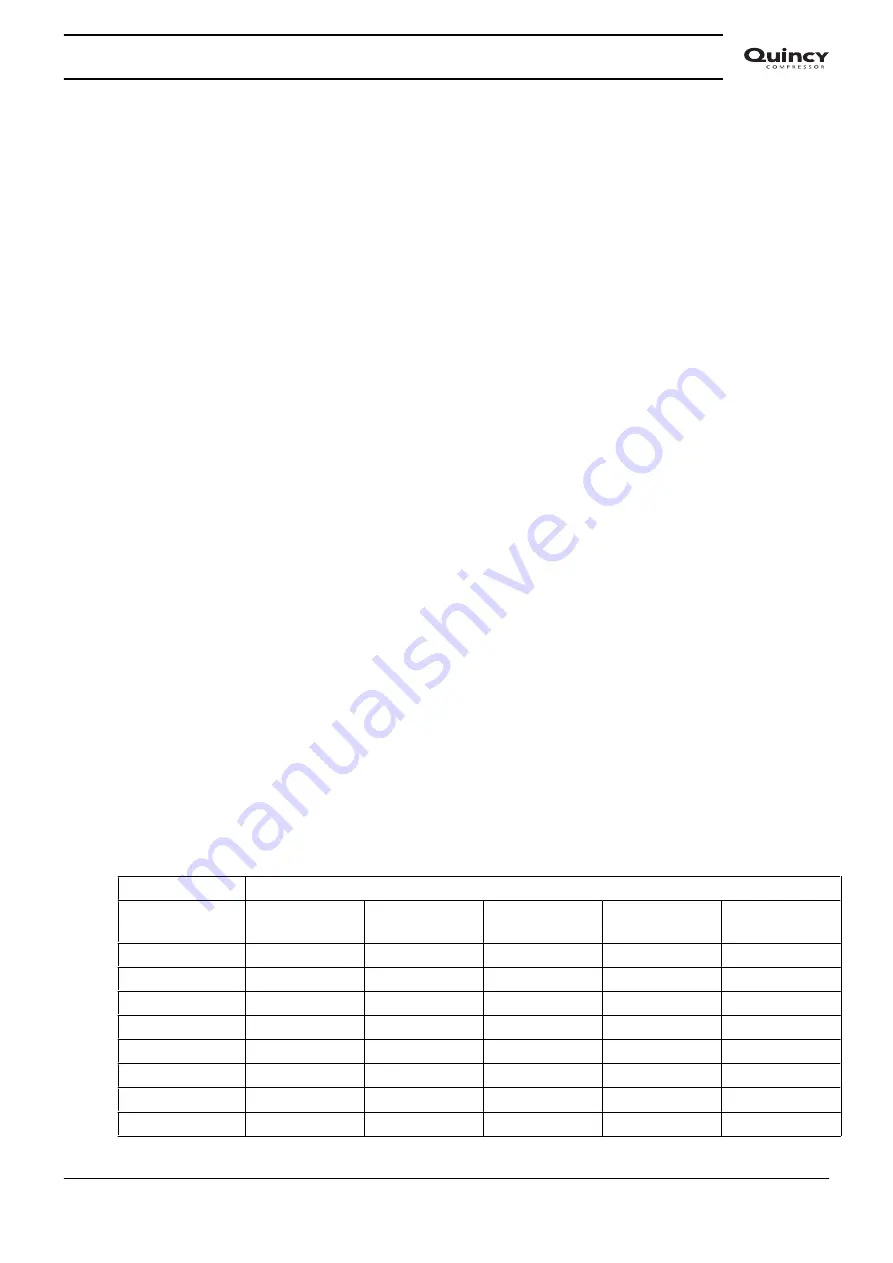

Cable sizing according CSA

Calculation method according CEC part 1, table 2 column 3: allowable ampacities for not more than 3 copper

conductors in raceway or cable (based on an ambient temperature of 30 °C (86 °F). Correction factors for

other temperatures table 5A column 3.

Maximum allowed current in function of the ambient temperature

Ambient temperature

Cable section

(AWG or kcmil)

30 °C (86 °F)

40 °C (104 °F)

45 °C (113 °F)

50 °C (122 °F)

55 °C (131 °F)

10

< 30 A

< 26 A

< 25 A

< 23 A

< 20 A

8

< 45 A

< 40 A

< 37 A

< 34 A

< 29 A

6

< 65 A

< 57 A

< 53 A

< 49 A

< 42 A

4

< 85 A

< 75 A

< 70 A

< 64 A

< 55 A

3

< 100 A

< 88 A

< 82 A

< 75 A

< 65 A

2

< 115 A

< 101 A

< 94 A

< 86 A

< 75 A

1

< 130 A

< 114 A

< 107 A

< 98A

< 85 A

1/0

< 150 A

< 132 A

< 123 A

< 113 A

< 98 A

Instruction book

2920 7101 21

85

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......