Never use a high pressure water jet to clean the compressor.

Instructions for air-cooled compressors

1. Stop the compressor, close the air outlet valve and switch off the voltage.

2. Remove any dirt from the coolers with a fibre brush. Never use a wire brush or metal objects.

3. Cover all parts under the coolers.

4. Next, clean with an air jet in the reverse direction to normal flow. Use low pressure air. If necessary, the

pressure may be increased up to 6 bar(e) (87 psig).

7.5

Filtering panel

Cleaning the filtering panel

Before carrying out any operation on the machine, ensure that the electric power supply has

been disconnected.

• Stop the compressor.

Close the air outlet valve and switch off the voltage.

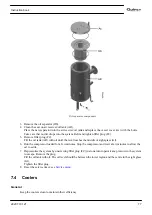

• Remove the air inlet filter panel(s) (FP1) and the cubicle filter (FP2).

• Clean the inlet filtering panel with a jet of air wash it with water, do not use solvents.

• Replace the cubicle filter.

• Once the operation has been completed, reassemble the filter panel.

Instruction book

78

2920 7101 21

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......