8

Problem solving

Warning

Before carrying out any maintenance, repair work or adjustment, press the stop button,

wait until the compressor has stopped, press the emergency stop button and switch off

the voltage. Close the air outlet valve and lock it if necessary.

Depressurize the air connection between the minimum pressure valve and the compressor

outlet ball valve. Turn slowly the air vent plug (Fa) just one turn to permit any pressure in

the system to escape.

If provided, open the manual condensate drain valves. Depressurise the compressor by

opening the oil filler plug one turn.

For location of components, see sections:

.

Open and lock the isolating switch.

The operator must apply all relevant

.

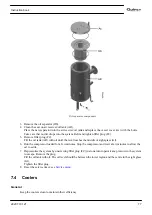

Position of air vent plug

Compressor

On compressors equipped with an AIRLOGIC² controller: if the alarm LED is lit or flashes, consult sections

-

Condition

Fault

Remedy

Compressor starts running, but

does not load after a delay time

Solenoid valve out of order

Replace valve

Inlet valve stuck in closed position Have valve checked

Leak in control air flexibles

Replace leaking flexible

Minimum pressure valve leaking

(when net is depressurised)

Have valve checked

-

Condition

Fault

Remedy

Compressor does not unload,

safety valve blows

Solenoid valve out of order

Replace valve

Inlet valve does not close

Have valve checked

Instruction book

80

2920 7101 21

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......