19

pulses therefore the speed measured=0 even though the motor is revolving.

Corrective Action: Troubleshoot PCB. MC33039 OSC Resistor-Capacitor combination may be out

of tolerance.

There can be excessive noise on the Hall effect sensor inputs, a bad MC33039, a bad microcontroller,

etc. Reset EE_ERROR byte by entering the calibration routine.

[E6]: EEPROM INITIALIZATION ERROR

Error action: This error prevents the CPM from entering the run mode.

Display: EEPROM ERR [E6]

Cause: During initial calibration certain variables in EEPROM are initialized. If there is some problem and

one of these variables cannot be written to EEPROM, error 6 is generated.

Corrective Action: If the problem recurs replace the microcontroller or the PCB.

[E7]: CYCLE COUNTER ERROR

Error Action: This error causes the microcontroller to burn 7 in the EE_ERROR EEPROM.

Display: *****STOP*****

Cause: Every time the unit pauses in extension a variable in the software called cycles since save

is incremented. Every six minutes of operation the timer is incremented and the total cycle count is

increased by the cycles since save, after which cycles since save is zeroed. If this process goes awry

and cycles since save becomes greater than 500 error 7 is generated.

Corrective Action: Contact the Technical Service Department and inform them of the error. The main

PCB may need to be replaced.

[E8]: MOTOR SPEED ERROR

Error Action: This error causes the microcontroller to burn 8 in the EE_ERROR EEPROM and causes the

CPM to stop.

Display: *****STOP*****

Cause: The maximum CPM rpms is less than 200. If the speed measured is greater than 254 counts in

one timer overflow (roughly 500 rpm) then error 8 is generated.

Corrective Action: Troubleshoot PCB. MC33039 OSC Resistor-Capacitor combination may be out

of tolerance. There can be excessive noise on the Hall effect sensor inputs, a bad MC33039, a bad

microcontroller, etc. Reset EE_ERROR byte by entering the calibration routine.

[E9]: START/STOP ERROR

Error Action: This error causes the microcontroller to burn 9 in the EE_ERROR EEPROM and causes the

CPM to stop.

Display: *****WAIT*****

Cause: The microcontroller has detected that the START/STOP key was depressed for more than 16.4

seconds. The START/STOP on the main or auxiliary controller may have been depressed for that period.

The PCC (Patient Control Cord) may have an open circuit. The main controller may have a short circuit.

It is normally open.

Corrective Action: Troubleshoot the controller and the main PCB. Reset EE_ERROR byte by entering the

calibration routine.

[E10]: KNEEPOT WIPER VOLTAGE TOO LOW

Error Action: This error causes the microcontroller to burn 10 in the EE_ERROR EEPROM and causes

the CPM to stop.

Display: ANGLE ERROR [E10]

Cause: The kneepot wiper or +8v may have an open. The main PCB may have a problem.

Corrective Action: Examine the kneepot, the kneepot cable and kneepot connector for possible opens

Summary of Contents for 480

Page 1: ...480 480E 480E PRO CPM Service and Technical Manual 2011 QAL Medical 05070812 3 Rev C 08 11...

Page 2: ......

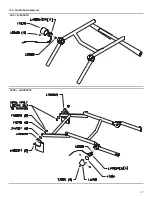

Page 25: ...25 14 Assembly Drawings 14 1 Main Assembly...

Page 26: ...26 14 2 Thigh Assembly...

Page 27: ...27 14 3 Cradle Sub Assembly 480 L480SA011 480E L480SA022...

Page 28: ...28 14 4 Foot Cradle Assembly...

Page 29: ...29 14 5 Ballscrew Assembly...

Page 30: ...30 14 6 480 U Bracket Slider Assembly...

Page 31: ...31 14 7 480E 480E PRO U Bracket Slider Assembly...

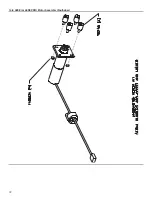

Page 32: ...32 14 8 480E or 480E PRO Motor Assembly Faulhaber...

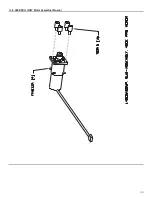

Page 33: ...33 14 9 480E PRO ONLY Motor Assembly Maxon...

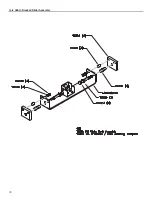

Page 34: ...34 14 10 Motion Controller Assembly 480 480E...

Page 36: ...36 14 12 480 Wiring Diagram...

Page 37: ...37 14 13 480E Wiring Diagram...

Page 39: ...39 14 15 480 480E Electrical Schematic...

Page 40: ...40...

Page 41: ...41...