20

and troubleshoot the main PCB. Perform the extension limit check in the calibration mode to assure that

the cradle is not traveling outside the kneepot’s voltage range. Reset EE_ERROR byte by entering the

calibration routine.

[E11]: KNEEPOT WIPER VOLTAGE TOO HIGH

Error Action: This error causes the microcontroller to burn 11 in the EE_ERROR EEPROM and causes

the unit to stop.

Display: ANGLE ERROR [E11]

Cause: The problem may be in the main PCB or the kneepot ground may have an open.

Corrective Action: Examine the kneepot, the kneepot cable and kneepot connector for possible opens

and troubleshoot the main PCB. Perform the extension limit check in the calibration mode to assure that

the cradle is not traveling outside the kneepot’s voltage range. Reset EE_ERROR byte by entering the

calibration routine (refer to section 10.0).

[E12]: Not used in the Model 480

[E13]: EEPROM VARIABLE ALLOCATION ERROR

Error Action: This causes the microcontroller to burn 13 in the EE_ERROR EEPROM.

Display: *****STOP*****

Cause: Each variable, in software, has a predetermined amount of EEP ROM dedicated to it. The

reason being that each byte of EEPROM can be written to only a finite number of times. Upon copying a

variable to EEP ROM the microcontroller checks that the copy matches the original. If it does not match

it goes on to the next byte of EEPROM and tries to write it again. Eventually there may come a time when

the variable runs out of the EEPROM that was allocated for it. This generates an error 13.

Corrective Action: Contact OrthoLogic Customer Service Department and inform them of the error. The

main PCB may need to be replaced. (There is enough EEPROM allocated for each variable to last for

more than a decade of constant use.)

[E14]: EEPROM POINTER ALLOCATION ERROR

Error Action: This causes the microcontroller to burn 14 in the EE_ERROR EEPROM.

Display:*****STOP*****

Cause: Each variable, in software, has a predetermined amount of EEP ROM dedicated to it. The

reason being that each byte of EEPROM can be written to only a finite number of times. Upon copying a

variable to EEP ROM the microcontroller checks that the copy matches the original. If it does not match

an "EEPROM pointer" byte is incremented so the microcontroller is directed to the next byte of EEPROM.

It proceeds to write the variable again. However, if the EEPROM pointer, a byte of EEPROM, can not be

incremented, an error 14 is generated. The variable cannot be written to the EEPROM correctly.

Corrective Action: Contact the Technical Service Department and inform them of the error. The main

PCB may need to be replaced.

[E15]: KNEEPOT WIPER VOLTAGE NOT CHANGING QUICKLY ENOUGH

Error Action: This causes the microcontroller to burn 15 in the EE_ERROR EEPROM and causes the

CPM to stop.

Display: *****STOP*****

Cause: If the CPM is in the run mode and the A/D converter reading doesn’t change by more than two

counts in a short, pre-determined amount of time, an error 15 is generated. The problem could be due to

a faulty kneepot or kneepot cable.

Corrective Action: Check for a faulty kneepot or kneepot cable. Reset EE_ERROR byte by entering the

calibration routine.

[E16]: CONFIGURATION ERROR

Summary of Contents for 480

Page 1: ...480 480E 480E PRO CPM Service and Technical Manual 2011 QAL Medical 05070812 3 Rev C 08 11...

Page 2: ......

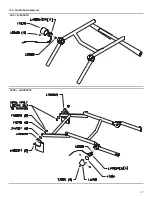

Page 25: ...25 14 Assembly Drawings 14 1 Main Assembly...

Page 26: ...26 14 2 Thigh Assembly...

Page 27: ...27 14 3 Cradle Sub Assembly 480 L480SA011 480E L480SA022...

Page 28: ...28 14 4 Foot Cradle Assembly...

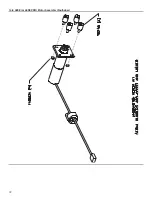

Page 29: ...29 14 5 Ballscrew Assembly...

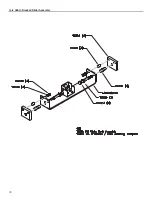

Page 30: ...30 14 6 480 U Bracket Slider Assembly...

Page 31: ...31 14 7 480E 480E PRO U Bracket Slider Assembly...

Page 32: ...32 14 8 480E or 480E PRO Motor Assembly Faulhaber...

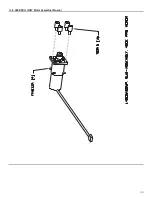

Page 33: ...33 14 9 480E PRO ONLY Motor Assembly Maxon...

Page 34: ...34 14 10 Motion Controller Assembly 480 480E...

Page 36: ...36 14 12 480 Wiring Diagram...

Page 37: ...37 14 13 480E Wiring Diagram...

Page 39: ...39 14 15 480 480E Electrical Schematic...

Page 40: ...40...

Page 41: ...41...