18

12 ERROR CODES

12.1 Error Codes (480/480E)

Important:

Errors are handled on a case by case basis. Detection of some errors stops the CPM. At that time

it will display an error code. It then burns the associated error code into the EE-ERROR byte in EEPROM. For

other lesser errors the only action taken is to burn the code into EEPROM. The specific actions of each error are

detailed in the following text. The EE-ERROR byte is reset by getting into the calibration mode. Refer to section

10.0 for further instructions.

[E1]: KNEE PIVOT ANGLE CALIBRATION ERROR

Error Action: This error prevents the CPM from entering the run mode.

Display: CALIBRATE [E1]

Cause: An invalid knee pivot angle calibration is indicated by bit 0 of EE_CAL_STATUS being zero.

Corrective Action: Re-calibrate the unit.

[E2]: MECHANICAL LIMIT CHECK OR FORCE CHECK VALIDATION ERROR

Error Action: See Display

Display: CALIBRATE [<-]

Cause: The extension limit check, the flexion limit check of the force check was not fully executed. This

action occurs when the unit is calibrated.

Corrective Action: Re-calibrate the unit.

[E3]: EE EXT CAL OR EE FLEX CAL EEPROM VARIABLE ERROR

Error Action: This error prevents the CPM from entering the run mode.

Display: CALIBRATE [E3]

Cause: On power-up the microcontroller checks the values of EE_EXT_CAL and EE_FLEX_CAL.

Limits are imposed on the value of these variables at calibration. If the values read from EEPROM are

not within these limits the variable is assumed to be corrupted and an error is generated.

Corrective action: Re-calibrate the unit.

[E4]: SOFTWARE TIMER ERROR

Error Action: This error causes the microcontroller to burn 4 in the EE_ERROR EEPROM.

Display: *****STOP*****

Cause: A software variable called Timer Overflow Interrupt

Count (T01 Count) is incremented every time the timer overflows. After the value of the T01 Count

becomes greater than 2746 the timer value in EEP ROM is incremented and the 2746 is subtracted from

T01 Count. If for some reason this process fails and T01 Count becomes greater than 32000 Error 4 is

generated.

Corrective Action: Contact the Technical Service Department and inform them of the error. The main

PCB may need to be replaced.

[E5]: MOTOR SPEED MEASUREMENT ERROR

Error Action: This error causes the microcontroller to burn 5 in the EE_ERROR EEPROM and causes the

CPM to stop.

Display: *****STOP*****

Cause: With every revolution of the motor the MC33039 detects when the sensor in the motor makes

a transition. That is when the sensor goes from high to low or low to high. It generates a pulse of fixed

width. The microcontroller measures the speed of the motor by counting the number of pulses that occur

in one timer overflow period. This happens in 131 seconds. When the unit runs too fast (over 230 RPM)

the time between sensor transitions becomes less than the pulse width. The microcontroller counts 0

Summary of Contents for 480

Page 1: ...480 480E 480E PRO CPM Service and Technical Manual 2011 QAL Medical 05070812 3 Rev C 08 11...

Page 2: ......

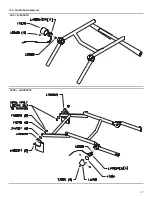

Page 25: ...25 14 Assembly Drawings 14 1 Main Assembly...

Page 26: ...26 14 2 Thigh Assembly...

Page 27: ...27 14 3 Cradle Sub Assembly 480 L480SA011 480E L480SA022...

Page 28: ...28 14 4 Foot Cradle Assembly...

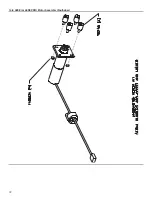

Page 29: ...29 14 5 Ballscrew Assembly...

Page 30: ...30 14 6 480 U Bracket Slider Assembly...

Page 31: ...31 14 7 480E 480E PRO U Bracket Slider Assembly...

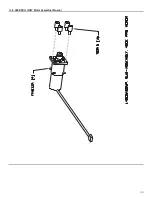

Page 32: ...32 14 8 480E or 480E PRO Motor Assembly Faulhaber...

Page 33: ...33 14 9 480E PRO ONLY Motor Assembly Maxon...

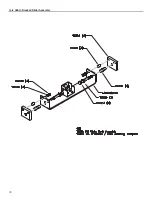

Page 34: ...34 14 10 Motion Controller Assembly 480 480E...

Page 36: ...36 14 12 480 Wiring Diagram...

Page 37: ...37 14 13 480E Wiring Diagram...

Page 39: ...39 14 15 480 480E Electrical Schematic...

Page 40: ...40...

Page 41: ...41...