Operating manual liquid ring vacuum pumps and compressors series TRH - TRS - TRM - TRV - SA & Systems type HYDROSYS - OILSYS

38

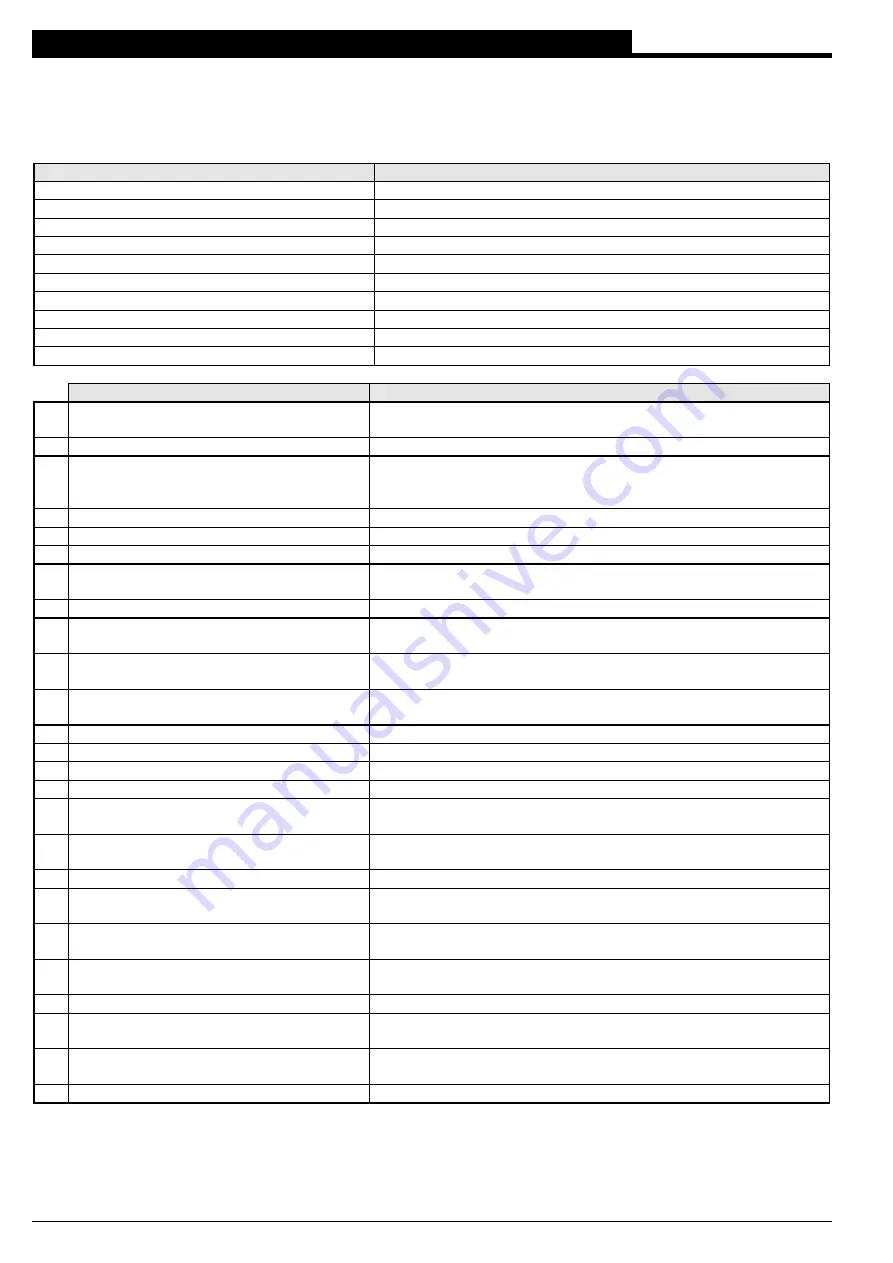

16 - TROUBLE SHOOTING: PROBLEMS, CAUSES AND SOLUTIONS

Consult the following tab. 9 when problems are experienced, if solutions are not found in this chart or should there be

any doubts, do not hesitate to contact POMPETRAVAINI or your local representative.

Tab. 9 -

LIST OF PROBLEMS

PROBLEM

LIST OF POSSIBLE CAUSES

Pump does not create or the vacuum is too low

1 - 2 - 3 - 4 - 9 - 11 - 18 - 19 - 22 - 23 - 24 - 25

Excessive noise

1 - 4 - 5 - 6 - 7 - 10 - 24

High power consumption

1 - 5 - 6 - 8 - 9 - 15 - 24 - 25

Vibration

5 - 6 - 7 - 8 - 10 - 12 - 13 - 24

Mechanical seal leaking

11 - 14

Pump looses liquid

11 - 19 - 23

Bearing failure

5 - 6 - 7

I

Pump does not start

1 - 6 - 20 - 21

J

Shaft partially or totally locked

6 - 10 - 15 - 16 - 21

Cavitation

3 - 4 - 8 - 9 - 17 - 24

CAUSES

SOLUTIONS

1

Defective motor or wired wrong

Check the voltage, the frequency, motor type, power

consumption, rotation, wiring connections, phase consistency

2

Leakage in suction piping

Repair piping; check valves for leakage

3

Service liquid high temperature

Lower the service liquid temperature;

check the level of the service liquid; adjust the cooling liquid flow;

adjust the radiator thermostat to lower temperature setting

4

Low service liquid flow

Increase the service liquid flow

5

Coupling misalignment

Re-align the coupling and the pump/motor assembly (see cap. 7)

6

Faulty bearing

Replace the bearing(see “Disassembly & Assembly Instructions”)

7

Cavitation

Open the anti-cavitation valve or set the relief valve to a lower

vacuum (see tab. 3)

8

High service liquid flow

Reduce the service liquid flow; adjust the by-pass valve

9

High back pressure

Check the discharge line for obstructions or high friction losses;

reduce the back-pressure to maximum 0.1 bar

10 Wrong pump/motor assembly

Verify that the base surface is level and that all pump feet are

resting on the surface, add spacers if required (see chapter 11)

11 Mechanical seal failure

Change the mechanical seal (see “Disassembly & Assembly

Instructions”)

12 Wrong pump mounting

Remount the pump (see chapter 7)

13 Piping weight resting on pump

Support the piping with hangers or other means (see chapter 11)

14 Inadequate seal lubrication

Check flushing liquid temperature, flow and pressure

15 Mineral deposits from hard water

Clean the pump

16 Foreign particles in pump

Disassemble the pump to remove the foreign objects (see

“Disassembly & Assembly Instructions”)

17 Low suction pressure

Open the vacuum regulating valve and/or the anti-cavitation

valve (see tab. 3)

18 Wrong pump rotation

Reverse the rotation (see chapter 8)

19 Bad gaskets

Replace the defective gaskets (see the “Disassembly &

Assembly Instructions”)

20 Wrong motor connections

Check the electrical connections (connectors, fuses, breakers)

and the power supply line (see chapter 8)

21 Pump seized

Disassemble and

repair the pump (see ”Disassembly &

Assembly Instructions”)

22 Pump undersized

Select a pump with higher capacity

23 Pump worn-out

Disassemble and repair the pump (see “Disassembly &

Assembly Instructions”)

24 Excessive liquid flow through suction line

Reduce the liquid flow through the pump suction; install a

centrifugal separator (cyclone) before the pump

25 Instrumentation out of calibration

Check the working characteristics, replace if required