Operating manual liquid ring vacuum pumps and compressors series TRH - TRS - TRM - TRV - SA & Systems type HYDROSYS - OILSYS

36

Fig. 37

Typical example of seal tank,

pressurised, cooling liquid and

instrumentation. (Instrument

location can vary)

NOTE:

Tank installation

must be at least 1 m

above the rotating

pump shaft

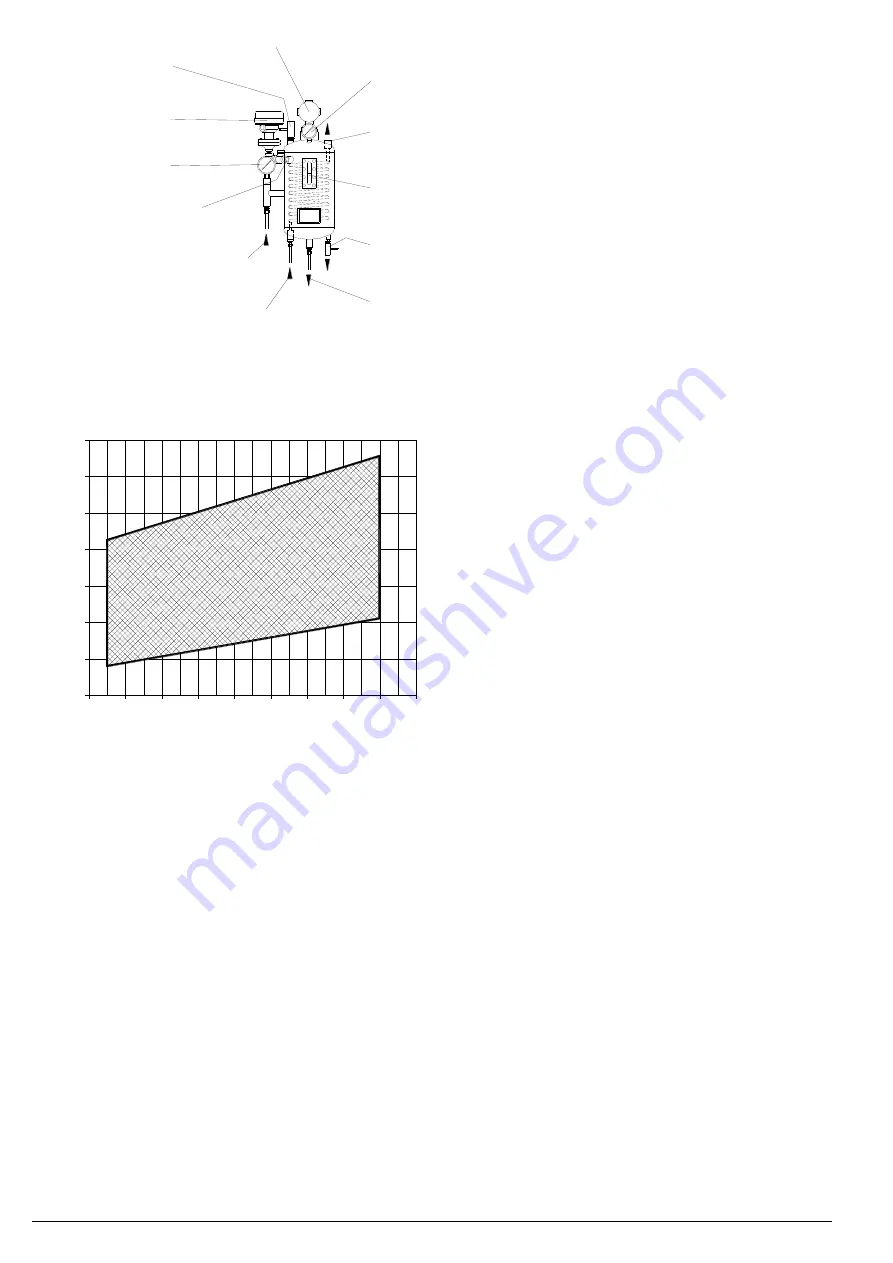

Tab. 7 - REQUIRED LIQUID FLOW TO FLUSH

MECHANICAL SEALS FROM OUTSIDE

SOURCE

mm = installed shaft seal diameter

bar = maximum pump working pressure (total of inlet

pressure and pump generated pressure as

measured at pump discharge flange)

l/1’ = required liquid flow (lit/min) for single seals or

double in series type seals (tol/-25%

depending upon temperatures)

NOTE: DOUBLE quantity of liquid flow for

double mechanical seals back-to-

back type.

CAUTION: Flushing liquid PRESSURE for back-to-back

double seals must be min 0.5 bar over the

max pump working pressure, while NOT more

than 0.3 bar over the atmospheric pressure in

case of double seals in series (TANDEM).

100

mm

16 mm

bar

l/1'

4

2

0

2

6

8

4

3

6

5

14

12

10

16

18

8

7

9

Minimum level sensor

Pressure switch

Tank fill plug

Temperature gauge

Liquid level (must be higher than

return liquid level from pump)

Inlet liquid (coming back from

mechanical seals)

Inlet cooling liquid

Outlet cooling liquid

Drain

Outlet liquid going to

mechanical seals

Gauge

Tank pressure plug