11

What You Can Do With This Machine

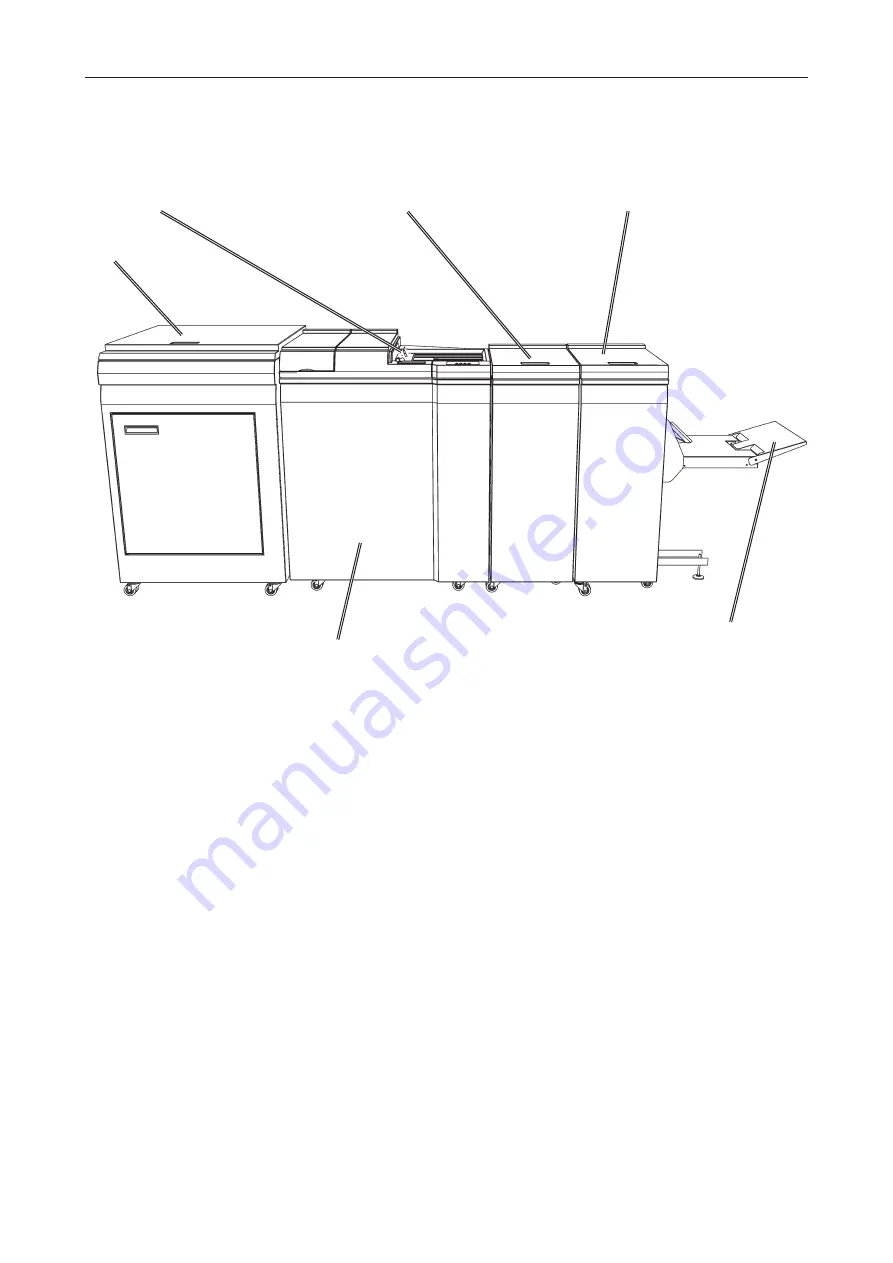

The RCT 30, Booklet Maker BM30, Trimmer TR30, Square Folder SQF30 and Cover

Feeder (CF300) forms a booklet making system that works online with the Printer.

The print-outs are transported through the RCT 30 (optional) prior to entering the Booklet

Maker. The RCT 30 is able to rotate small(er) sheets from long edge feed to short edge feed,

to increase printer productivity. In order to avoid color prints to break or dissolve at the spine

after folding, the Creaser can prepare the cover sheet for that.The Bleed Trimmer trims the

long sides of the sheets to shape the print-outs to the desired format. After that, the print-outs

are transported into the stapler area and compiled. From the CF30 Cover Feeder (optional),

if present, any type of covers, colored or black and whites, can be added to the printed set.

The Booklet Maker now jogs and then staples the set. The set is then transported further to

the folding area where the set is folded into a booklet and then fed out to the belt stacker.

When a larger number of sheets are folded an effect called creeping occurs. In order to rectify

creep, the TR30 Trimmer (optional) can be attached after the Booklet Maker. The booklets

are then transported from the Booklet Maker into the Trimmer where the trail edge will be

cut off. If a TR30 Trimmer is installed to the BM30 Booklet Maker, you can attach the SQF30

Square Folder (optional). The printouts, which have been stapled, folded and trimmed will

be fed into the SQF30. The SQF30 will flatten the spine of the booklet square. The booklets

will, after passing the SQF30, have the look of a perfect bound book. The booklets are then

fed out to the Belt Stacker. Undocked or off-line, the Booklet Maker can be used as a stand-

alone unit for hand feeding.

CF30 Cover Feeder (optional) TR30 Trimmer (optional)

BM30 Booklet Maker

SQF30 Square Folder (optional)

Belt Stacker

RCT 30

Summary of Contents for BOOKLET MAKER Pro 30

Page 6: ...Page intentionally blank...

Page 10: ...10 Page intentionally blank...

Page 21: ...21 1 RCT 30 2 3 4 1 Top cover 2 Infeed slot 3 Upstream docking assembly 4 Slide door...

Page 32: ...1 32 Consumables To reorder staples please use following part numbers XNA 8R3838 XE 8R3839...

Page 34: ...1 34 Page intentionally blank...

Page 62: ...62 Page intentionally blank...

Page 80: ...7 80 Cleaning the paper path sensors 5x continues Rotator sensor Registration sensor...

Page 84: ...7 84 Page intentionally blank...

Page 92: ......