DA50S/DA55S/DA70S/DA75S AddressRight™ Printers Service Manual

6-5

Adjustments • 6

DA50S/DA55S (WS51/WS56) Adjustments

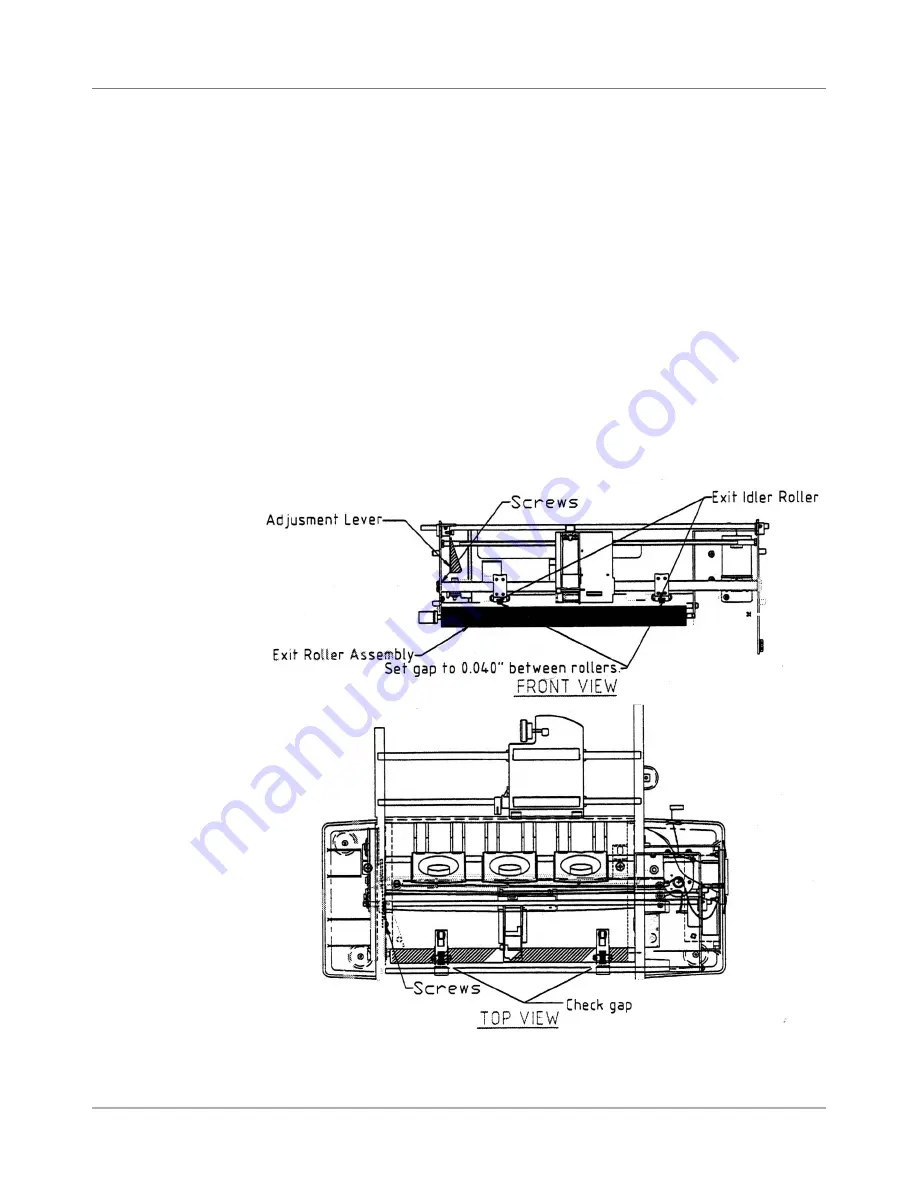

6.6 Exit Roller

Idler Assembly

Figure 6-4 DA50S/DA55S Shuttle Mechanism

1. Raise the thickness adjustment lever to its highest point.

2. Check the gap between the exit roller assembly and the bottom of the

exit idler rollers. A 0.040” feeler gauge must pass freely between both

rollers. NOTE: Loosen the screws securing the adjustable roller assem-

bly on the right to raise or lower the right side of the exit roller assembly.

3. Check that the bar is pulled all the way forward and is level. NOTE: loos-

en screws to adjust bar when it is angled forward or backward.

4. Check the gap with a 0.065” feeler gauge. The gauge should not slide

between the rollers.

5. Secure screws once the gap is found.

6. Also check the gap between the small diameter rollers and the floor. The

gap should be between 0.1100” and 0.180”. Replace the non-conforming

exit slide roller if the gap is not between 0.100” and 0.180” and repeat

steps 1 to 6 again.