TABLE III-I. INSPECTION REPORT (cont)

Nature of Inspection

E. CABIN GROUP (cont.)

15.Inspect operation of fuel selector valve....................................................................

O

O

O

16.Inspect condition of heater controls and ducts..........................................................

O

O

O

17.Inspect condition and operation of air vents.............................................................

O

O

O

18.Inspect condition of air conditioner ducts.................................................................

O

O

O

19.Remove and clean air conditioner evaporator filter..................................................

O

O

O

F. FUSELAGE AND EMPENNAGE GROUP

WARNING

Read Note 28 before completing this inspection group.

1. Remove inspection plates and panels (See Note 33)................................................

O

O

O

2. Inspect baggage door, latch, and hinges for condition operation, and security........

O

O

O

3. Inspect battery, box, and cables for corrosion, damage, frayed cables, and loose

terminals. (Service every 30 days) Refer to Service Manual or box instructions ....

O

O

O

O

4. Inspect all electronic components for security .........................................................

O

O

O

5. Inspect bulkheads and stringers for damage.............................................................

O

O

O

6. Inspect antenna mounts and electrical wiring for security and corrosion in plugs. .

O

O

O

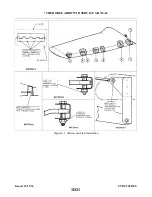

7. Inspect hydraulic pump motor brushes (Read Note(s) 19 and 28)...........................

O

O

O

8. Check hydraulic pump fluid level (Service as required) ..........................................

O

O

O

O

9. Inspect hydraulic pump lines and hoses for damage and leaks ...............................

O

O

O

10.Inspect for obstructions and contamination in inlet of backup landing gear

extender actuator inlet head (if applicable) (Read Note 27).....................................

O

O

O

O

11.Inspect air conditioner system for Freon leaks ........................................................

O

O

O

12.Check Freon charge in sight gauge of receiver-dehydrator (Refer to Service

O

O

O

O

13.Inspect air conditioner condenser air scoop rigging.................................................

O

O

O

O

14.Inspect fuel lines, hoses, valves, sender units, and gauges for damage and operation .

O

O

O

15.Inspect security of all hoses and lines.......................................................................

O

O

O

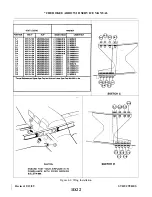

16.Inspect vertical fin and rudder surfaces for damage.................................................

O

O

O

17.Inspect rudder hinges, horn, and attachments for damage and operation ................

O

O

O

18.Inspect vertical fin attachments ...............................................................................

O

O

O

19.Inspect rudder hinge bolts for excess wear (Replace as required)............................

O

O

O

20.Inspect rudder control stops to ensure stop has not

become loose and jamb nut is tight...........................................................................

O

O

O

21.Inspect stabilator surfaces for damage......................................................................

O

O

O

22.Inspect stabilator, tab hinges, horn, and attachments for damage and operation......

O

O

O

23.Inspect stabilator attachments (Refer to latest

O

O

O

50

500

1000

100

Inspection Time (Hrs)

CHEROKEE ARROW III SERVICE MANUAL

1D11

Interim Revision: 2/21/95

INSPECTION

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...