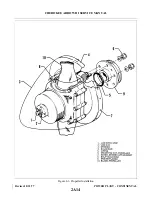

Density Controller

The density controller is designed to allow the engine to develop full

rated power no matter what ambient temperature and pressure

conditions are. This controller regulates wastegate bleed oil only at

full throttle position to maintain a constant air density at the injector

inlet. The pressure and temperature sensing bellows of the con troller

react to pressure and temperature changes between the fuel injector

inlet and the turbocharger compressor. The bellows, filled with dry

nitrogen gas, maintains a constant density by allowing the pressure to

increase as temperature increases. Movement of the bellows re-

positions the bleed valve, causing a change in quantity of bleed oil,

which changes oil pressure to the wastegate piston.

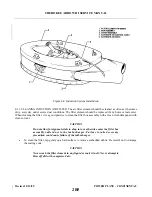

NOTE

The density controller is designed to keep the air density constant at the

injector entrance. As ambient air temperature increases or density decreases

due to change in altitude a higher manifold pressure is required to maintain

a constant density, also resulting in a higher injector inlet temperature. This

is why wide open throttle manifold pressure increases with either altitude or

outside air temperature. In a full throttle climb, a gain of 3 to 4 inches of

manifold pressure between sea level and critical altitude will be seen.

Differential Pressure

This controller uses a diaphragm rather than a bellows as is found in

Controller

the density controller. It is used in conjunction with the density

controller. Its function is to override the density controller so that the

compressor discharge pressure is not held at an unnecessarily high

level when lower manifold pressure is being used. The diff e r e n t i a l

controller will usually maintain a compressor discharge pressure

(deck pressure) approximately 6.5” Hg above the selected manifold

pressure. In this system, the density controller is only effective at

wide open engine throttle conditions.

Ground Boosted or

These phrases indicate that the engine depends on a certain amount of

Ground Turbocharged

turbocharging at sea level to produce the advertised horsepower. An

engine that is so designed will usually include a lower compression

ratio to avoid detonation.

Deck Pressure

The pressure measured in the area downstream of the turb compressor

discharge and upstream of the engine throttle valve. This should not

be confused with manifold pressure.

Manifold Pressure

The pressure measured downstream of the engine throttle valve and is

almost directly proportioned to the engine power output.

Normalizing

If a turbocharger system is used only to regain power losses caused by

decreased air pressure of high altitude, it is considered that the engine

has been “normalized”.

Added: 5/1/80

2B1

CHEROKEE ARROW III SERVICE MANUAL

POWER PLANT - CONTINENTAL

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...