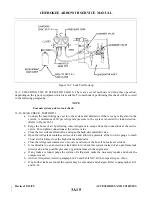

14-5. SPECIAL SERVICING PROCEDURES. The air conditioning system should be serviced by a qualified

shop with trained personnel. The following procedure and precautions should be observed.

The efficiency of this system depends upon the pressure-temperature relationship of pure refrigerant. As

long as the system contains only pure refrigerant plus a specified amount of compressor oil (which is mixed

with the refrigerant) it is considered to be chemically stable. Foreign materials within the system will affect the

chemical stability, contaminate the system, and decrease its efficiency.

I. GENERAL REFRIGERATION SYSTEM PROCEDURES.

A. REFRIGERANT SAFETY PRECAUTIONS.

1. Refrigerant 12 (commonly known at R-12 or Freon 12) is odorless and colorless in either the

liquid or gaseous state. R-12 for charging refrigeration systems is supplied in pressurized

containers (approx. 70 psi at 70°F) in liquid form. Since this material is essentially inert at

room temperatures, the dangers are primarily associated with the pressure and the refrigeration

effects of the release and subsequent evaporation of this pressurized liquid.

2. Wear suitable eye protection when handling R-12 due to the possibility of freezing of the eye

if contacted by escaping liquid refrigerant. If liquid R-12 does strike the eye, the following

action should be taken.

a.

DO NOT RUB THE EYE.

b.

Splash large quantities of cool water into the eye to raise the temperature.

c.

Tape on an eye patch to avoid the possibility of dirt entering the eye.

d.

Rush to a physician or hospital for immediate professional aid.

e.

DO NOT ATTEMPT TO TREAT IT YOURSELF.

3. If liquid R-12 strikes the skin, frostbite can occur. Treat with cool water and protect with

petroleum jelly.

4. Do not discharge large quantities of R-12 into closed rooms. It may displace most of the air in

the room and this could cause oxygen starvation. Gaseous R-12 is heavier than air and flows

to the bottom of a container.

5. Do not discharge R-12 into an open flame or onto a very hot surface (500°F+). Poisonous

phosgene gas is generated by the action of the heat on the refrigerant.

6. Do not apply direct flame or other high heat source to a R-12 container due to the high

pressures which will result. If any heating is done to R-12 containers, the container pressure

should be monitored and kept below 150 psi.

B. SYSTEM SERVICING PRECAUTIONS.

1. Systems should be discharged slowly to prevent the escape of liquid refrigerant and the loss of

the lubricating oil.

2. Systems should not be left open to the atmosphere when discharged. Moisture and other

contamination may enter and damage open systems.

3. Never introduce anything but pure refrigerant and refrigerant oil into a system.

4. Keep refrigerant oil containers tightly sealed and clean to prevent absorption of moisture or

other contamination.

5. Use only approved refrigeration oil in the compressor. If any doubt exists about the cleanliness

of the compressor oil, replace it with new oil.

6. Never reuse oil removed from the system. Discard it.

7. When Loctite Refrigerant Sealant has been used on a joint it must be heated to 400°F prior to

disassembly. Loctite must be used to seal any pipe threads in the system lines.

8. Replace the receiver-dehydrator assembly on any system which has been operating with a leak

allowing air to enter the system. If a receiver-dehydrator is left open to the atmosphere it

should be replaced due to the loss of effectiveness of the drying compound it contains.

Revised: 2/13/89

3A11

CHEROKEE ARROW III SERVICE MANUAL

ACCESSORIES AND UTILITIES

Summary of Contents for ARROW III

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A4...

Page 12: ...THIS PAGE INTENTIONALLY LEFT BLANK 1A12...

Page 94: ...Figure 4 2 Wing Installation Revised 2 13 89 1D22 CHEROKEE ARROW III SERVICE MANUAL STRUCTURES...

Page 171: ...lH3 INTENTIONALLY LEFT BLANK...

Page 172: ...lH4 INTENTIONALLY LEFT BLANK...

Page 286: ...THIS PAGE INTENTIONALLY LEFT BLANK Revised 2 13 89 2A8...

Page 528: ...INTENTIONALLY LEFT BLANK 2K10 THRU 2L24 2K10...