5-6

Control Loops

DC590+ Series DC Digital Drive

Current Control

The field current loop can accept a demand directly from the plant and/or an outside field weakening loop and forms the error signal which is the

difference between demand and feedback. The error signal is fed into a P + I compensator which produces the output of the field loop, i.e. the field

firing angle signal.

The firing angle signal is translated into a certain time delay from the mains zero cross point (obtained via the same Phase-Lock-Loop as for the

armature) and this results into a firing command being issued to the field bridge every 1/2 of a mains cycle in steady-state.

Voltage Control

This offers the facility of an open-loop voltage control for motors which do not provide in the nameplate the field current rating. The field voltage is

controlled by the specified FLD. VOLTS RATIO which defaults to 90.0%. This is the maximum dc Volts that can be obtained for a given ac RMS

input in a single-phase rectifier, i.e. 370V dc for 415V ac supply. The specified ratio determines directly the firing angle at which the controller

operates and therefore the thermal effects on the field resistance as well as mains voltage variations are not compensated for. It is also worth noting

that in this mode the field overcurrent alarm is not active (since there is no current scaling) and therefore this mode is not recommended for use with

supplies much greater than the field voltage rating.

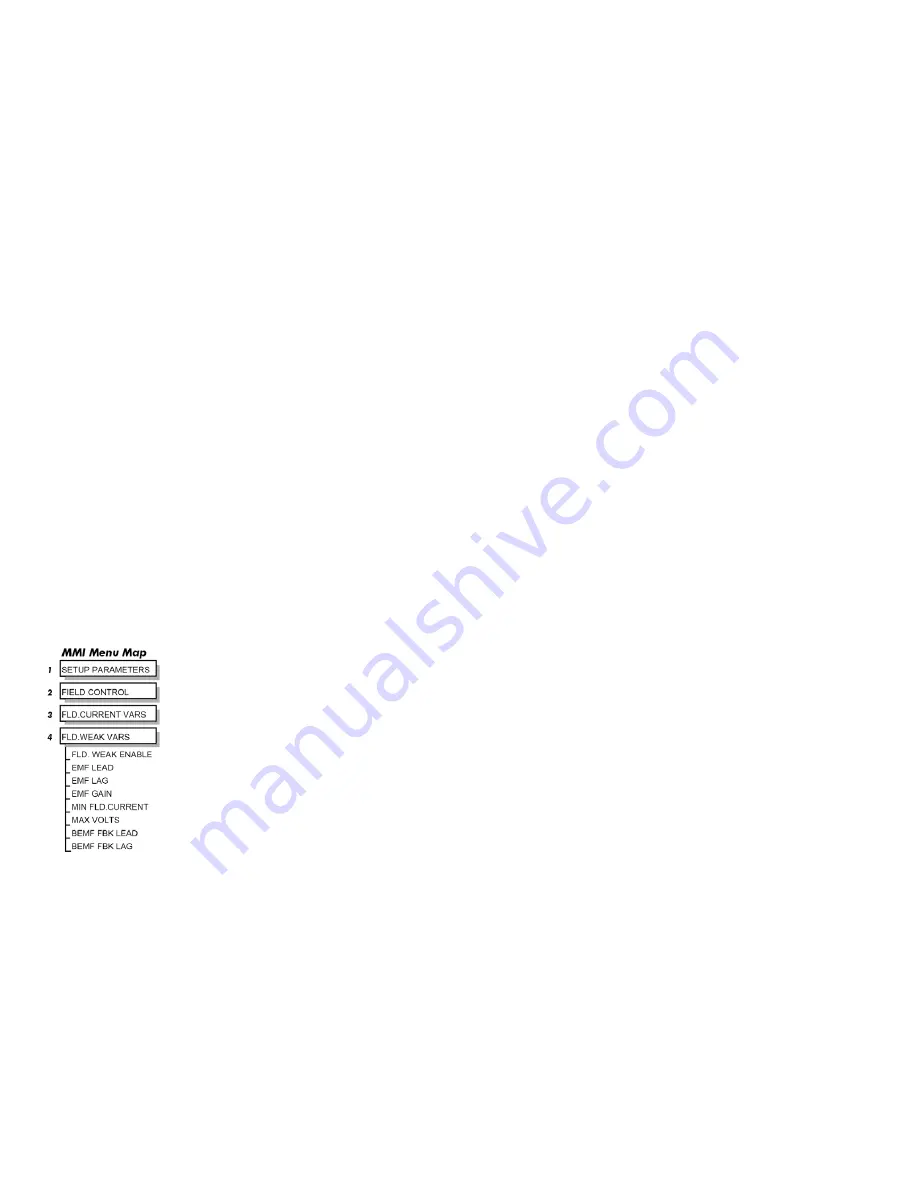

Field Weakening

Motor field weakening is used to extend the speed region of the motor above its base speed (the motor speed resulting at rated armature voltage, rated

armature current and rated field current), in a constant power mode of operation (motor torque reducing with increasing speed).

Note that the motor should be rated for field-weakened operation, in terms of rotational speed and reduced field current, before utilising this mode.

The drive includes a field weakening loop that, above base speed, can control the field current demand to the correct level required to maintain motor

back-EMF at a pre-defined level.

NOTE

Field weakening is not possible when running with Armature Volts feedback. Although field weakening can be “Enabled” in this

instance, a software interlock clamps the field demand at 100% and will not allow the field weakening to reduce it.

When the back-EMF measurement is higher than the MAX VOLTS setting (default 100%) the excess voltage is presented to the field weakening gain-

limited PI controller as an error, and this controller reduces the field current demand accordingly.

The gain-limited controller is tuned as follows:

1.

Ensure that the armature current, speed and field current loops are correctly tuned.

2.

Enable field weakening control (FLD. WEAK ENABLE = ENABLE), with analogue tachogenerator, encoder or microtach speed feedback,

correctly installed and configured for extended speed operation.

3.

Run the drive and slowly increase the speed demand so that the field is being weakened by the gain-limited PI controller. Change the MAX

VOLTS parameter down and up by 10% to generate field current transients.

4.

Alternately increase the P gain (using the dc-gain parameter EMF GAIN) and reduce the integral time-constant (parameter EMF LEAD) until

the loop is correctly tuned (see the Current Loop "Tuning Hints" above).

Summary of Contents for 590+ series

Page 2: ......

Page 14: ...Cont 12...

Page 16: ...DC590 Series DC Digital Drive...

Page 20: ......

Page 32: ...2 12 Product Overview DC590 Series DC Digital Drive...

Page 34: ......

Page 130: ...3 96 Installing the Drive DC590 Series DC Digital Drive...

Page 132: ......

Page 164: ...4 32 Operating the Drive DC590 Series DC Digital Drive...

Page 166: ......

Page 174: ...5 8 Control Loops DC590 Series DC Digital Drive...

Page 176: ......

Page 202: ......

Page 222: ...7 20 Trips and Fault Finding DC590 Series DC Digital Drive...

Page 224: ......

Page 242: ......

Page 272: ...DC590 Series DC Digital Drive...

Page 288: ...B 16 Certification DC590 Series DC Digital Drive...

Page 290: ......

Page 342: ...C 52 Parameter Specification Tables DC590 Series DC Digital Drive...

Page 344: ......

Page 365: ...Programming D 21 DC590 Series DC Digital Drive Functional Description...

Page 494: ...D 150 Programming DC590 Series DC Digital Drive Programming Block Diagram Sheet 1...

Page 495: ...Programming D 151 DC590 Series DC Digital Drive Programming Block Diagram Sheet 2...

Page 496: ...D 152 Programming DC590 Series DC Digital Drive Programming Block Diagram Sheet 3...

Page 497: ...Programming D 153 DC590 Series DC Digital Drive Programming Block Diagram Sheet 4...

Page 502: ...D 158 Programming DC590 Series DC Digital Drive...

Page 504: ......

Page 506: ...E 2 Technical Specifications DC590 Series DC Digital Drive...

Page 507: ...Technical Specifications E 3 DC590 Series DC Digital Drive...