VCB-X Controller Field Technical Guide

INSTALLATION & WIRING

19

WARNING:

When using a single transformer to power more

than one controller or expansion module, the

correct polarity must always be maintained be-

tween the boards. Failure to observe correct

polarity will result in damage to the VCB-X

Controller and expansion modules.

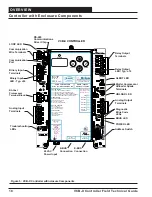

Please carefully read and apply the following information when

wiring the VCB-X Controller or the Expansion Modules. See

Figures

6 & 7

for VCB-X input and output wiring. See

Figures 22 & 23

for

the VCB-X EM1 Expansion Module wiring,

Figures 34 & 35

for

VCB-X EM2 Expansion wiring, and

Figure 36

for the VCB-X 12

Relay Expansion Module wiring.

1. All wiring is to be in accordance with local and national

electrical codes and speci

fi

cations.

2. All 24 VAC wiring must be connected so that all ground

wires remain common. Failure to follow this procedure

can result in damage to the controller and connected

devices.

3. Minimum wire size for 24 VAC wiring should be

18-gauge.

4. Minimum wire size for all sensors should be 24-gauge.

Some sensors require 2-conductor wire and some require

3-or 4-conductor wire.

5. Minimum wire size for 24 VAC thermostat wiring

should be 22 gauge.

6. Be sure that all wiring connections are properly inserted

and tightened into the terminal blocks. Do not allow

wire strands to stick out and touch adjoining terminals

which could potentially cause a short circuit.

7. When communication wiring is to be used to intercon-

nect VCB-X Controllers together or to connect to other

communication devices, all wiring must be plenum-

rated, minimum 18-gauge, 2-conductor, twisted pair with

shield. WattMaster can supply communication wire that

meets this speci

fi

cation and is color coded for the

network or local loop. Please consult your WattMaster

distributor for information. If desired, Belden #82760 or

equivalent wire may also be used.

8. Before applying power to the VCB-X Controller,

be sure to recheck all wiring connections and

terminations

thoroughly.

Important Wiring Considerations

General

Correct wiring of the VCB-X Controller is the most important

factor in the overall success of the controller installation process. In

general, most VCB-X Controllers are factory installed and wired at

the AAON

®

factory. It is also possible to purchase these controllers

through your local AAON

®

/Orion representative for installation in

the

fi

eld. Some of the following information pertains to

fi

eld wiring

and may not apply to your installation if it was pre-wired at the

factory. However, if troubleshooting of the controller is required, it

is a good idea to be familiar with the system wiring, no matter if it

was factory or

fi

eld wired.

Controller Mounting

When the controller is to be

fi

eld mounted, it is important to mount

the controller in a location that is free from extreme high or low

temperatures, moisture, dust, and dirt. See

Table 1

for a list of

the required operating conditions for the VCB-X Controller and

associated expansion modules.

The VCB-X Controller is housed in a plastic enclosure. It is designed

to be mounted by using the 3 mounting holes in the enclosure base.

The VCB-X Controller needs to be installed in an environment

which can maintain a temperature range between -30°F and 150°F

not to exceed 90% RH levels (non-condensing). Be careful not to

damage the electronic components when mounting the controller.

Considerations

The VCB-X Controller and expansion modules must be connected

to a 24 VAC power source of the proper size for the calculated VA

load requirements. All transformer sizing should be based on the

VA rating listed in

Table 1

.

Contr

ol

De

vice

V

olta

ge

V

A

Load

Temper

atur

e

Humidity

(Non-

Condensing)

OE335-26B-VCB-X-A

VCB-X Controller

24VAC

8

-30°F to

150°F

90% RH

OE336-23-EM1-A

24VAC

5

-30°F to

150°F

90% RH

OE336-23-EM2-A

24VAC

5

-30°F to

150°F

90% RH

OE358-23E-12R-A

24VAC

15

-30°F to

150°F

90% RH

Table 1: Voltage and Environment Requirements