7

•

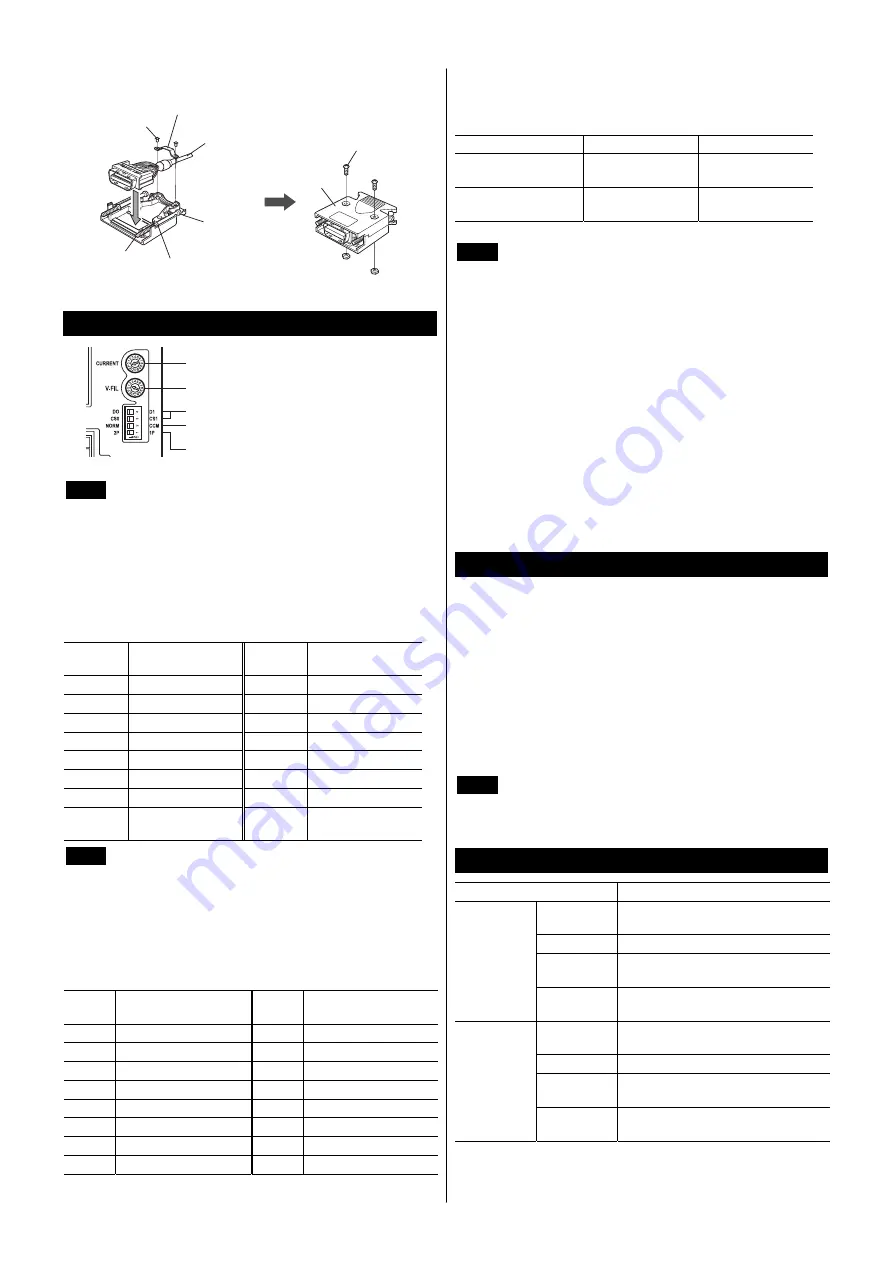

Assembling the connector

I/O signal cable

Cable clamp

Screw (M2.5)

Case

Connector

Place the spring

washer outside

the case.

Screw (M2)

Screw (M2.5)

Tightening torque:

0.5 to 0.55 N·m

(71 to 78 oz-in)

Align the washer in the

depression in the case.

Setting

㪚㫌㫉㫉㪼㫅㫋㩷㫊㪼㫋㫋㫀㫅㪾㩷㫊㫎㫀㫋㪺㪿㩷䋨㪫㪿㪼㩷㪽㪸㪺㫋㫆㫉㫐㩷㫊㪼㫋㫋㫀㫅㪾㩷㫀㫊㩷㵰㪝㪅㵱䋩

㪪㫇㪼㪼㪻㩷㪽㫀㫃㫋㪼㫉㩷㫊㪼㫋㫋㫀㫅㪾㩷㫊㫎㫀㫋㪺㪿㩷䋨㪫㪿㪼㩷㪽㪸㪺㫋㫆㫉㫐㩷㫊㪼㫋㫋㫀㫅㪾㩷㫀㫊㩷㵰㪈㪅㵱䋩

㪩㪼㫊㫆㫃㫌㫋㫀㫆㫅㩷㫊㫎㫀㫋㪺㪿㪼㫊㩷䋨㪫㪿㪼㩷㪽㪸㪺㫋㫆㫉㫐㩷㫊㪼㫋㫋㫀㫅㪾㩷㫀㫊㩷㵰㪛㪇㪃㩷㪚㪪㪇㪅㵱䋩

㪧㫌㫃㫊㪼㩷㫀㫅㫇㫌㫋㩷㫄㫆㪻㪼㩷㫊㪼㫃㪼㪺㫋㫆㫉㩷㫊㫎㫀㫋㪺㪿

䋨㪫㪿㪼㩷㪽㪸㪺㫋㫆㫉㫐㩷㫊㪼㫋㫋㫀㫅㪾㩷㫀㫊㩷㵰㪦㪝㪝㪅㵱䋩

㪚㫆㫅㫋㫉㫆㫃㩷㫄㫆㪻㪼㩷㫊㪼㫃㪼㪺㫋㫆㫉㩷㫊㫎㫀㫋㪺㪿

䋨㪫㪿㪼㩷㪽㪸㪺㫋㫆㫉㫐㩷㫊㪼㫋㫋㫀㫅㪾㩷㫀㫊㩷㵰㪥㪦㪩㪤㪅㵱䋩

Note

The new settings of the resolution switches or pulse

input mode select switch will become effective after the

power is cycled. If a 24 VDC power supply is used, also

cycle the 24 VDC power supply.

Operating current

The operating current can be set using the current setting switch. The

operating current is set with the value which multiplied the

maximum output current by the operating current rate (%).

Dial

setting

Operating current

rate (%)

Dial

setting

Operating current

rate (%)

0 6.3 8 56.3

1 12.5 9 62.5

2 18.8 A 68.8

3 25.0 B 75.0

4 31.3 C 81.3

5 37.5 D 87.5

6 43.8 E 93.8

7 50.0 F

100

(factory setting)

Note

If the operating current is too low, starting of the

actuator and its position hold function may be affected.

Do not lower the operating current more than

necessary.

Speed filter

The actuator response to input pulses can be adjusted using the speed

filter setting switch (V-FIL).

Dial

setting

Speed filter time

constant (ms)

Dial

setting

Speed filter time

constant (ms)

0 0 8 30

1

1 (factory setting)

9

50

2 2 A 70

3 3 B

100

4 5 C

120

5 7 D

150

6 10 E 170

7 20 F 200

Resolution

The resolution per revolution of the motor output shaft can be set

using the resolution switches.

Resolution switches

D0

D1

CS0

1000 P/R

(0.36°/pulse)

∗

500 P/R

(0.72°/pulse)

CS1

10000 P/R

(0.036°/pulse)

5000 P/R

(0.072°/pulse)

∗

Factory setting

Note

When changing the resolution using the CS input, use

the switches in “CS0”/“D0” or “CS0”/“D1” combination. If

the CS input is turned ON when “CS1” is selected, the

resolution will not be changed.

Control mode

The control mode of the driver can be toggled between the normal

mode and current control mode using the control mode selector

switch.

NORM: Normal mode

CCM: Current control mode

Pulse input mode

The pulse input mode of the driver can be set using the pulse input

mode selector switch.

OFF: 2-pulse input mode

ON: 1-pulse input mode

Inspection

It is recommended that periodic inspections be conducted for the

items listed below after each operation of the actuator. If an

abnormal condition is noted, discontinue any use and contact your

nearest office.

During inspection

•

Check for a blocked opening of the driver case.

•

Are any of the driver mounting screws or power connection

terminal screws loose?

•

Is there attachment of dust, etc., on the driver?

•

Are there any strange smells or appearances within the driver?

Note

The driver uses semiconductor elements. Handle the

driver with care since static electricity may damage

semiconductor elements. Static electricity may damage

the driver.

General specifications

Degree of protection

IP20

Ambient

temperature

0 to +50 °C (+32 to +122 °F)

(non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 1000 m (3300 ft.) above sea

level

Operation

environment

Surrounding

atmosphere

No corrosive gas, dust, water or oil

Ambient

temperature

−

20 to +60 °C (

−

4 to +140 °F)

(non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 3000 m (10000 ft.) above sea

level

Storage

environment

Shipping

environment

Surrounding

atmosphere

No corrosive gas, dust, water or oil