4

Names and functions of parts

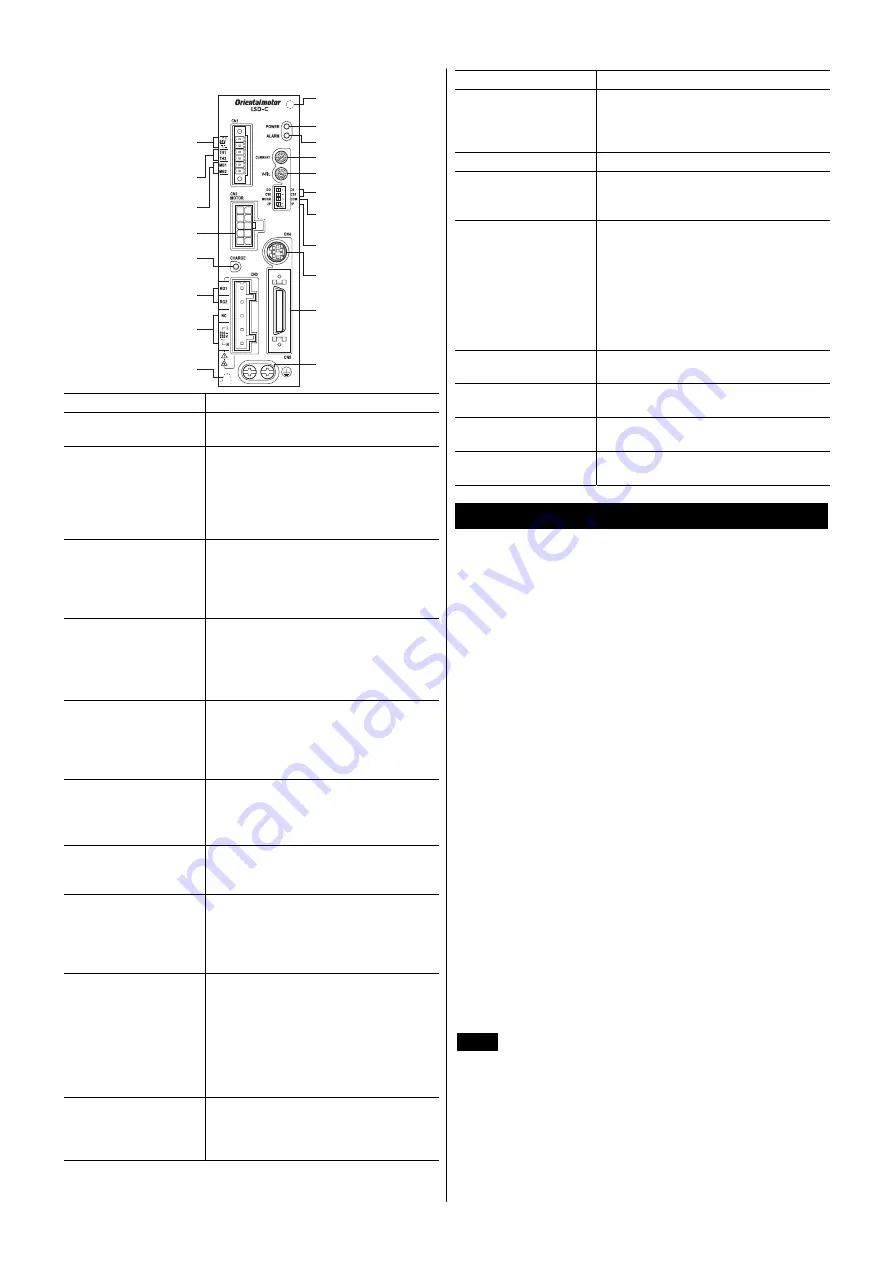

POWER LED

ALARM LED

Current setting switch

Speed filter setting switch

Control mode selector

switch

Resolution switches

Pulse input mode

selector switch

Data edit connector

(CN4)

Motor connector (CN2)

Mounting hole

(at the back)

Mounting hole

(at the back)

CHARGE LED

I/O signals connector

(CN5)

Protective Earth Terminal

Electromagnetic brake

terminal (CN1)

Regeneration resistor

thermal input terminal (CN1)

24 VDC power supply

input terminal (CN1)

Regeneration resistor

terminal (CN3)

Power supply

input terminal (CN3)

Name Description

POWER LED (green)

This LED is lit while the main power or

24 VDC power is input.

ALARM LED (red)

This LED will blink when an alarm

generates (a protective function is

triggered). You can check the generated

alarm (triggered protective function) by

counting the number of times the LED

blinks.

CHARGE LED (red)

This LED will lit while the main power is

input. After the main power has been

turned off, the LED will turn off once the

residual voltage in the driver drops to a

safe level.

Current setting switch

(CURRENT)

This switch adjusts the operating current.

A desired current can be set as a

percentage (%) of the rated output

current.

(The factory setting is “F.”)

Speed filter setting

switch (V-FIL)

This switch adjusts the actuator

response. Adjust the switch if you want to

suppress actuator vibration or cause the

actuator to start/stop smoothly.

(The factory setting is “1.”)

Resolution switches

(D0/D1, CS0/CS1)

These two switches are used to toggle

the resolution per revolution of the motor

output shaft.

(The factory settings are “D0” and “CS0”).

Control mode selector

switch (NORM/CCM)

This switch toggles the driver between

the normal mode and current control

mode. (The factory setting is “NORM.”)

Pulse input mode

selector switch (2P/1P)

This switch is used to toggle between the

1-pulse input mode and 2-pulse input

mode according to the pulse output mode

of the controller.

(The factory setting is “2P.”)

24 VDC power supply

input terminal (CN1)

[24V]

Connects 24 VDC. Once a 24 VDC power

supply is connected, you can check the

contents of alarms that have generated

even when the main power is cut off. If an

actuator with an electromagnetic brake is

used, be sure to connect a 24 VDC power

supply as the electromagnetic brake

power.

Regeneration resistor

thermal input terminal

(CN1) [TH1, TH2]

Connects the regeneration unit

RGB100

.

If no regeneration unit is connected, plug

in the CN1 connector to short the TH1

and TH2 terminals.

Name Description

Electromagnetic brake

terminal (CN1) [MB1,

MB2]

Connects the lead wires of "cable for

electromagnetic brake" (24 VDC).

MB1: Electromagnetic brake

−

(black)

MB2: Electromagnetic brake + (white)

Motor connector (CN2)

Connects the actuator.

Regeneration resistor

terminal

(CN3) [RG1, RG2]

Connects the regeneration unit

RGB100

.

Power supply input

terminal (CN3)

•

Single-phase 100-115 V, single-phase

200-230 V

L, N: Connects a single-phase power

supply

•

Three-phase 200-230 V

L1, L2, L3: Connects a three-phase

power supply

•

NC: Not used.

Data edit connector

(CN4)

Connects a PC in which the

MEXE02

has

been installed, or the

OPX-2A

.

I/O signals connector

(CN5)

Connects the I/O signals.

Protective Earth

Terminal

Ground this terminal using a grounding

wire larger than AWG16 (1.25 mm

2

).

Mounting holes

(2 locations at the back)

These mounting holes are used to secure

the driver with screws.

Installation

Location for installation

The driver is designed and manufactured for installation in

equipment.

Install it in a well-ventilated location that provides easy access for

inspection. The location must also satisfy the following conditions:

•

Inside an enclosure that is installed indoors (provide vent holes)

•

Operating ambient temperature 0 to +50 °C (+32 to +122 °F)

(non-freezing)

•

Operating ambient humidity 85% or less (non-condensing)

•

Area that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

•

Area not exposed to direct sun

•

Area free of excessive amount of dust, iron particles or the like

•

Area not subject to splashing water (rain, water droplets), oil (oil

droplets) or other liquids

•

Area free of excessive salt

•

Area not subject to continuous vibration or excessive shocks

•

Area free of excessive electromagnetic noise (from welders,

power machinery, etc.)

•

Area free of radioactive materials, magnetic fields or vacuum

•

Up to 1000 m (3300 ft.) above sea level

Installation method

The driver is designed so that heat is dissipated via air convection

and conduction through the enclosure. Install the driver on a flat

metal plate [material: aluminium, 200×200×2 mm (7.87×7.87×0.08

in.) equivalent ] having excellent heat conductivity.

Note

•

Install the driver in an enclosure whose pollution

degree is 2 or better environment, or whose degree of

protection is IP54 minimum.

•

Do not install any equipment that generates a large

amount of heat or noise near the driver.

•

Do not install the driver underneath the controller or

other equipment vulnerable to heat.

•

Check ventilation if the ambient temperature of the

driver exceeds 50 °C (122 °F).

•

Be sure to install (position) the driver vertically.