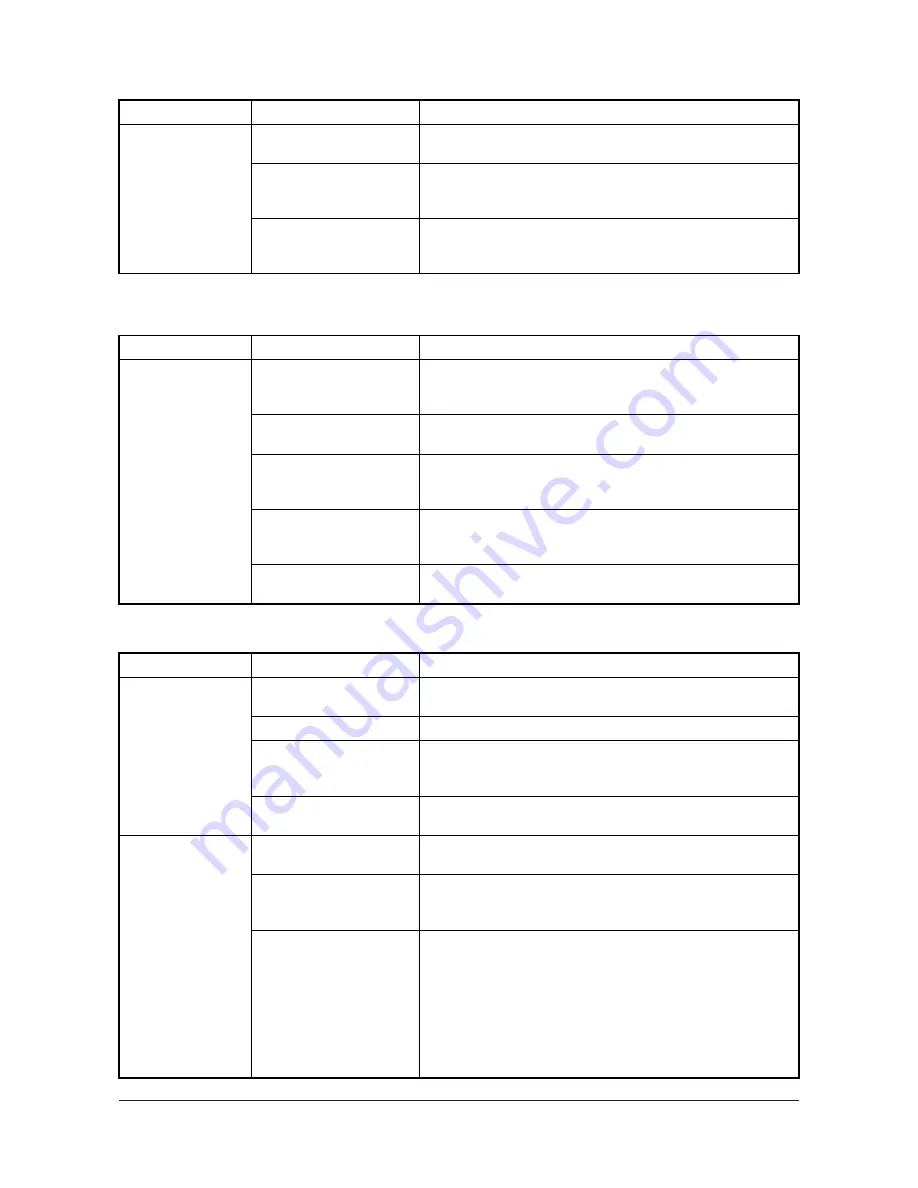

3H3

1-4-21

Multi job tray

Punch unit

(5)

The pressures

release solenoid

does not operate.

Broken pressures release

solenoid coil.

Check for continuity across the coil. If none, replace the pressures

release solenoid.

Poor contact in the pres-

sures release solenoid con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Defective centerfold unit

main PWB.

Run maintenance item U240 and check if CN6-27 and CN6-28 on

the centerfold unit main PWB go low. If not, replace the centerfold

unit main PWB.

Problem

Causes

Check procedures/corrective measures

(1)

The multi job tray ele-

vation motor does

not operate.

Poor contact in the multi job

tray elevation motor con-

nector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Broken multi job tray eleva-

tion motor gear.

Check visually and replace the multi job tray elevation motor if

necessary.

Defective multi job tray ele-

vation motor.

Run maintenance item U240 and check if the multi job tray eleva-

tion motor operates when YC8-7 and YC8-8 on the finisher drive

PWB go low. If not, replace the multi job tray elevation motor.

Defective finisher drive

PWB.

Run maintenance item U240 and check if YC8-7 and YC8-8 on

the finisher drive PWB go low. If not, replace the finisher drive

PWB.

Defective finisher main

PWB.

Run maintenance item U240 and check if YC12-14 on the finisher

main PWB goes low. If not, replace the finisher main PWB.

Problem

Causes

Check procedures/corrective measures

(1)

The punch motor

does not operate.

Poor contact in the punch

motor connector terminals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Broken punch motor gear.

Check visually and replace the punch motor if necessary.

Defective punch motor.

Run maintenance item U240 and check if the punch motor oper-

ates when YC3-3 and YC3-4 on the punch PWB go low. If not,

replace the punch motor.

Defective punch PWB.

Run maintenance item U240 and check if YC3-3 and YC3-4 on

the punch PWB go low. If not, replace the punch PWB.

(2)

The punch solenoid

does not operate.

Broken punch solenoid coil. Check for continuity across the coil. If none, replace the punch

solenoid.

Poor contact in the punch

solenoid connector termi-

nals.

Reinsert the connector. Also check for continuity within the con-

nector cable. If none, remedy or replace the cable.

Defective finisher main

PWB.

Run maintenance item U240 and check if YC15-7 and YC15-8 on

the finisher main PWB go low. If not, replace the finisher main

PWB.

Problem

Causes

Check procedures/corrective measures

Y1043

71-8

Service Manual