User’s Guide Océ CS9160 printer

76

AP-40790 – Rev 2.0 -23/08/2011,

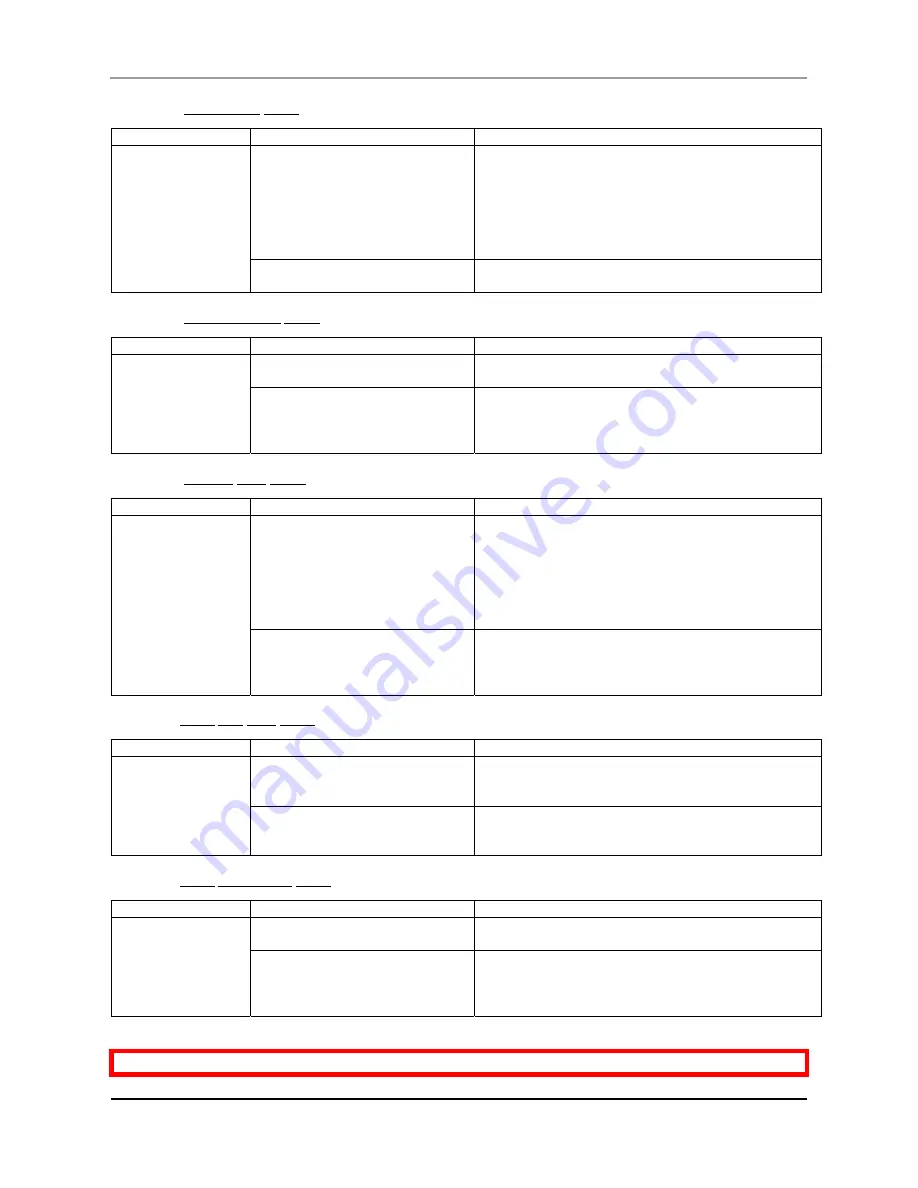

4.7.1.4

Init.Adj.Print menu

Setup Item

Setting Value

Description

Feed Length

100 mm to <250 mm> to 500 mm

Change the length (feed length) of the media feed

direction for the initial adjust print.

[Enter] key:

The setting value is determined.

"Printing" is displayed and the initial adjust print is

started.

After printing, the printer enters in the normal status.

—

[Cancel] key: Cancel the setting value and shift to

the previous hierarchy.

4.7.1.5

Init.Adj.Change menu

Setup Item

Setting Value

Description

Init.

200.0 mm to <250.0 mm> to

300.0 mm

Set up Initial Adjust Change.

—

[Enter] key: Save the setting and shift to the previous

hierarchy.

[Cancel] key: Cancel the setting and shift to the

previous hierarchy.

4.7.1.6

Confirm Print menu

Setup Item

Setting Value

Description

Feed Length

100 mm to <250 mm> to 500 mm

Change the length (feed length) of the media feed

direction for the Confirm Print.

[Enter] key:

The setting is determined.

"Printing" is displayed and initial adjust print is

started.

After printing, the printer enters the normal status.

—

[Enter] key: Save the setting and shift to the previous

hierarchy.

[Cancel] key: Cancel the setting and shift to the

previous hierarchy.

4.7.1.7 Micro Adj. Print menu

Setup Item

Setting Value

Description

Micro Adj. Print

Printing

Print the PF pattern (micro adjustment) with a focus

on the micro adjustment value.

Printing interval: ± 1 pulse

—

[Cancel] key: Shift to the previous hierarchy.

If the printer is terminated during printing it shifts to

the previous level.

4.7.1.8 Micro Adj.Change menu

Setup Item

Setting Value

Description

Micro Adj.Change

–20 pulse to <0 pulse > to 20

pulse

Set up the Micro Adjustment Change.

—

[Enter] key: Save the setting and shift to the previous

hierarchy.

[Cancel] key: Cancel the setting and shift to the

previous hierarchy.

Be sure to read and understand the safety warnings before handling the printer.

Summary of Contents for CS9160

Page 1: ...Oc CS9160 User s Guide Eco Solvent Low Solvent Ultra Bio Lactite...

Page 2: ...User s Guide Oc CS9160 printer 2 AP 40790 Rev 2 0 23 08 2011...

Page 6: ...User s Guide Oc CS9160 printer 6 AP 40790 Rev 2 0 23 08 2011...

Page 8: ...User s Guide Oc CS9160 printer 8 AP 40790 Rev 2 0 23 08 2011...

Page 17: ...User s Guide Oc CS9160 printer 17 AP 40790 Rev 2 0 23 08 2011 5 6 7 8 9...

Page 18: ...User s Guide Oc CS9160 printer 18 AP 40790 Rev 2 0 23 08 2011...

Page 114: ...User s Guide Oc CS9160 printer 114 AP 40790 Rev 2 0 23 08 2011...

Page 131: ...User s Guide Oc CS9160 printer 131 AP 40790 Rev 2 0 23 08 2011...