ID50 Series Panel - Installation, Commissioning & Configuration Manual

Configuration

Mode

39

997-263, Issue 4

September 2002

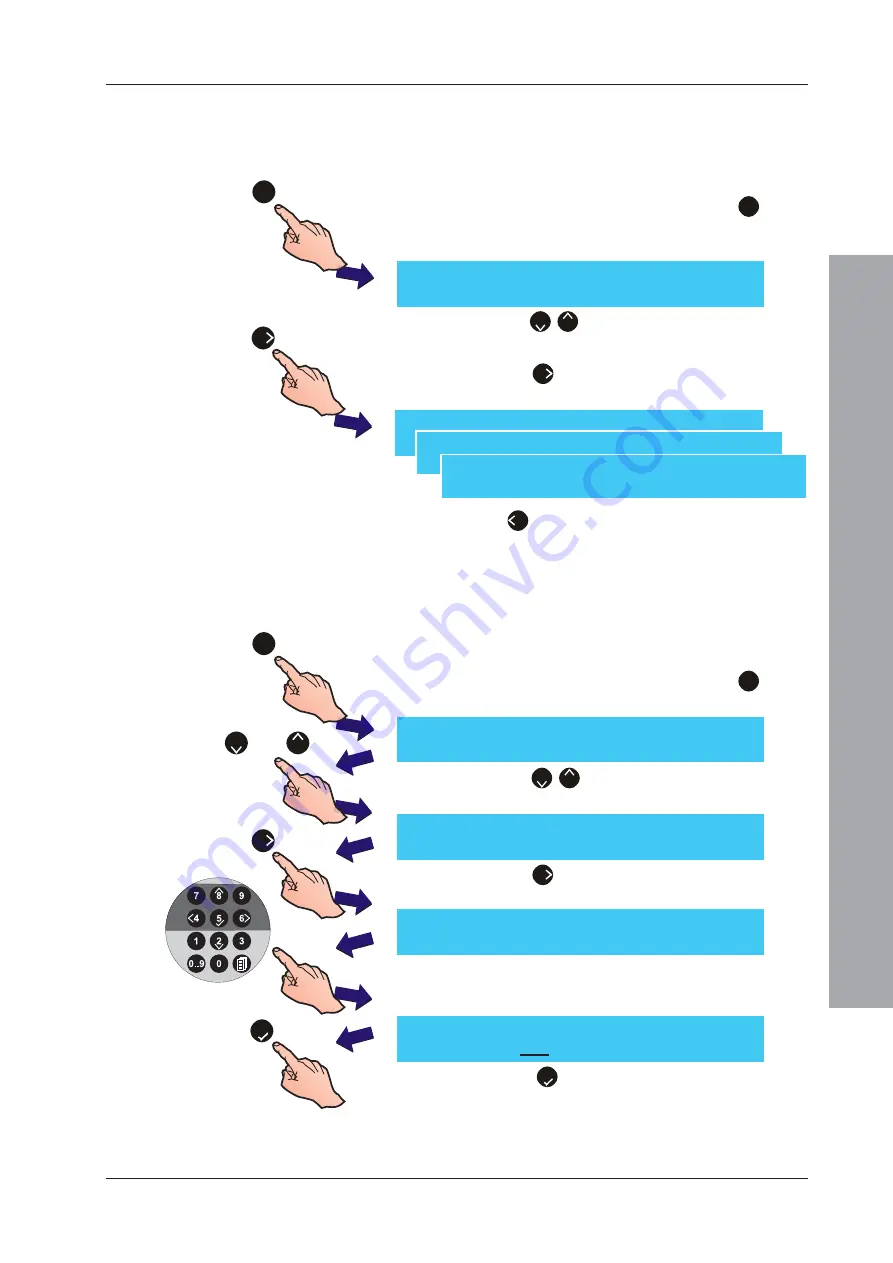

5.5.3 Primary/Extend Delay Timers

The Primary Delay Timer allows an initial investigation time

of up to 300 seconds (default 30 seconds) to be entered or

changed. The Extend Delay Timer allows an additional delay

(default - 3 minutes) to be entered or changed. The total

delay time cannot exceed 10 minutes. To set delay times:

1

From the Commissioning menu, press the

1

button

on the numeric keypad to enter the Setup menu.

2

Press the

2

/

8

buttons to step through the Setup

menus to display the Primary Delay Time menu.

3

Press the

6

button. The display then prompts you

for the new value:

4

Enter the required delay time using the numeric

buttons; (e.g. to set the delay time to the maximum

value of 300 seconds, first enter 3, then enter 0, 0).

5

Press the

5

button to confirm and return to the

Setup menus.

6

Repeat steps 1 to 5 for the Extend Delay Time, using

the Extend Delay Time display and a maximum value

of 10 minutes.

5.5.2 Date Format

This option is used to select one of three available date formats

for display on the LCD. The options available are dd/mm/yyyy,

mm/dd/yyyy or yyyy/mm/dd. To change the date format:

1

From the Commissioning menu, press the

1

button

on the numeric keypad to enter the Setup menu. The

LCD shows the Language menu.

Press the

2

/

8

buttons to scroll through the Setup

menu until the Date Format menu is displayed.

2

Press the

6

button to step through the alternative

Date Format settings.

3

Press

4

to return to the Commissioning menu.

[Setup]

Date Format = mm/dd/yyyy

> : Change

×

: More

< : Exit

[Setup] Language =

English

> : Change

×

: More

< : Exit

[Setup]

Date Format = yyyy/mm/dd

> : Change

×

: More

< : Exit

[Setup]

Date Format = dd/mm/yyyy

> : Change

×

: More

< : Exit

1

6

[Setup]

Primary Delay Time = 30 Seconds

> : Change

×

: More

< : Cancel

[Setup]

Primary Delay Time = 30 Seconds

Enter new value ____

3

: Confirm

< : Cancel

[Setup]

Primary Delay Time = 30 Seconds

Enter new value 300

3

: Confirm

< : Cancel

1

6

or

8

2

5

[Setup] Language =

English

> : Change

×

: More

< : Exit