SDS Meters

3

Part 1009912E

E

2005 Nordson Corporation

Description

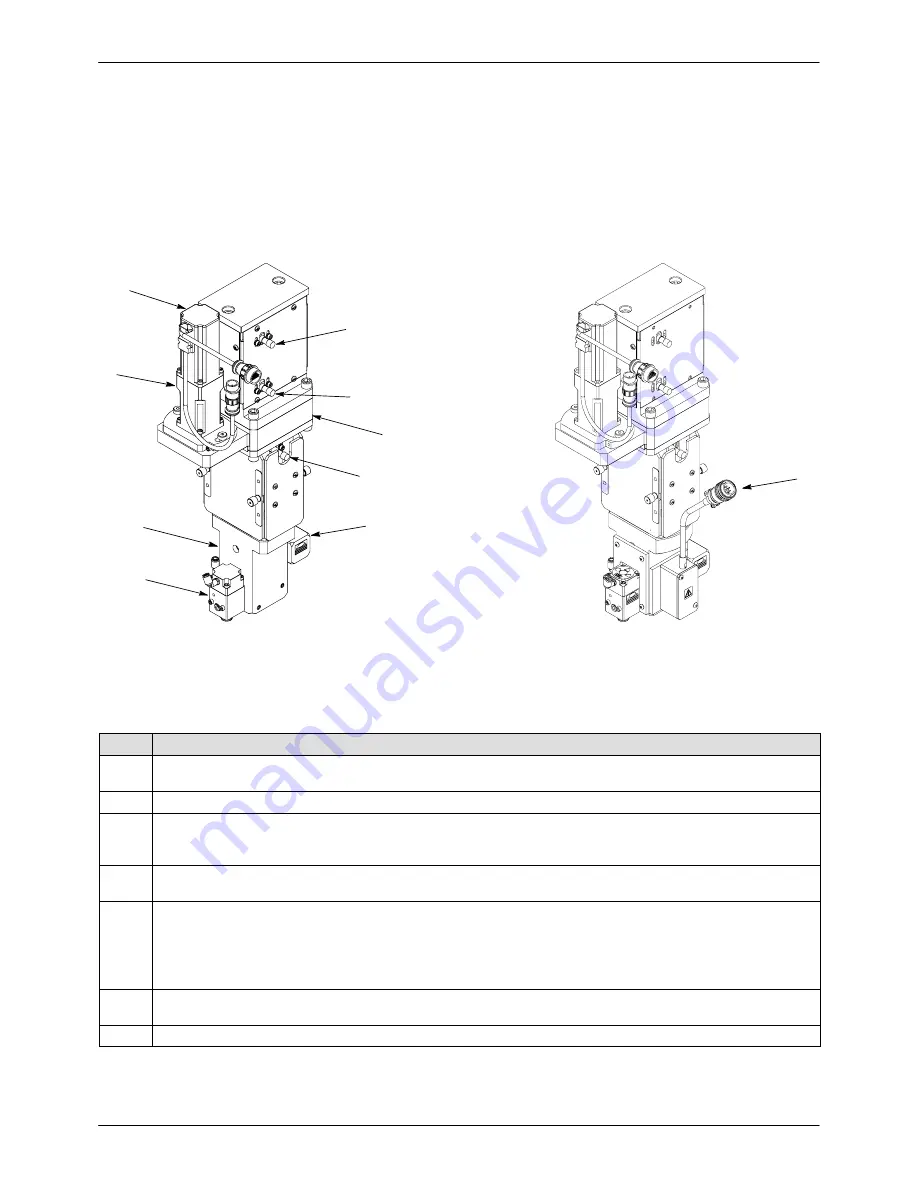

See Figure 1. The SDS meters are designed for

high-speed application of single-component materials. A

closed-coupled dispense valve and electric servo

controlled metering allows for accurate dispensing.

Six SDS meters are available:

S

40- and 90-cc; unheated

S

40- and 90-cc; 120v and 240V heated

Table 1 lists the major SDS meter components.

1

5

2

6

7

4

3

3

3

40-CC SDS Meter

Heated 40-CC SDS Meter

8

Figure 1

Typical SDS Meters

Table 1 SDS Meter Components

Item

Description

1

Servo motor—The servo motor links directly to the gearbox on top of the belt housing. Encoder and power

leads connect to the rear of the servo motor.

2

Gearbox—The gearbox links to the servo motor and reduces the servo motor output to a 15:1 fixed ratio.

3

Proximity sensors—The proximity sensors feed positional information through a junction box to the

controller. Two proximity sensors are triggered by the ball screw and anti-rotation block, serving as

emergency stops. One proximity sensor indicates that the metering cylinder is full.

4, 5

Inlet (4) and Outlet (5) Valves—Two compact, high-cycle valves mounted to the metering cylinder. The

valves serve as material inlet/outlet ports.

6

Metering Cylinder—The metering cylinder mounts to the drive train through the use of four tie rods. It is filled

by positive pressure from a Rhino bulk unloader.

The metering cylinder is equipped with a rupture disk assembly. If the internal cylinder pressure exceeds

5000 psi (345 bar), the rupture disk breaks and releases pressure, preventing serious equipment damage or

personal injury.

7

Drive Train—The drive train includes the ball screw assembly, anti-rotation block, and driven gear. A bearing

supports the ball screw assembly inside the bearing housing base.

8

Cordset—Cable connection to system controller or J-box.