BenchMike Pro Instruction Handbook: Setup

4-39

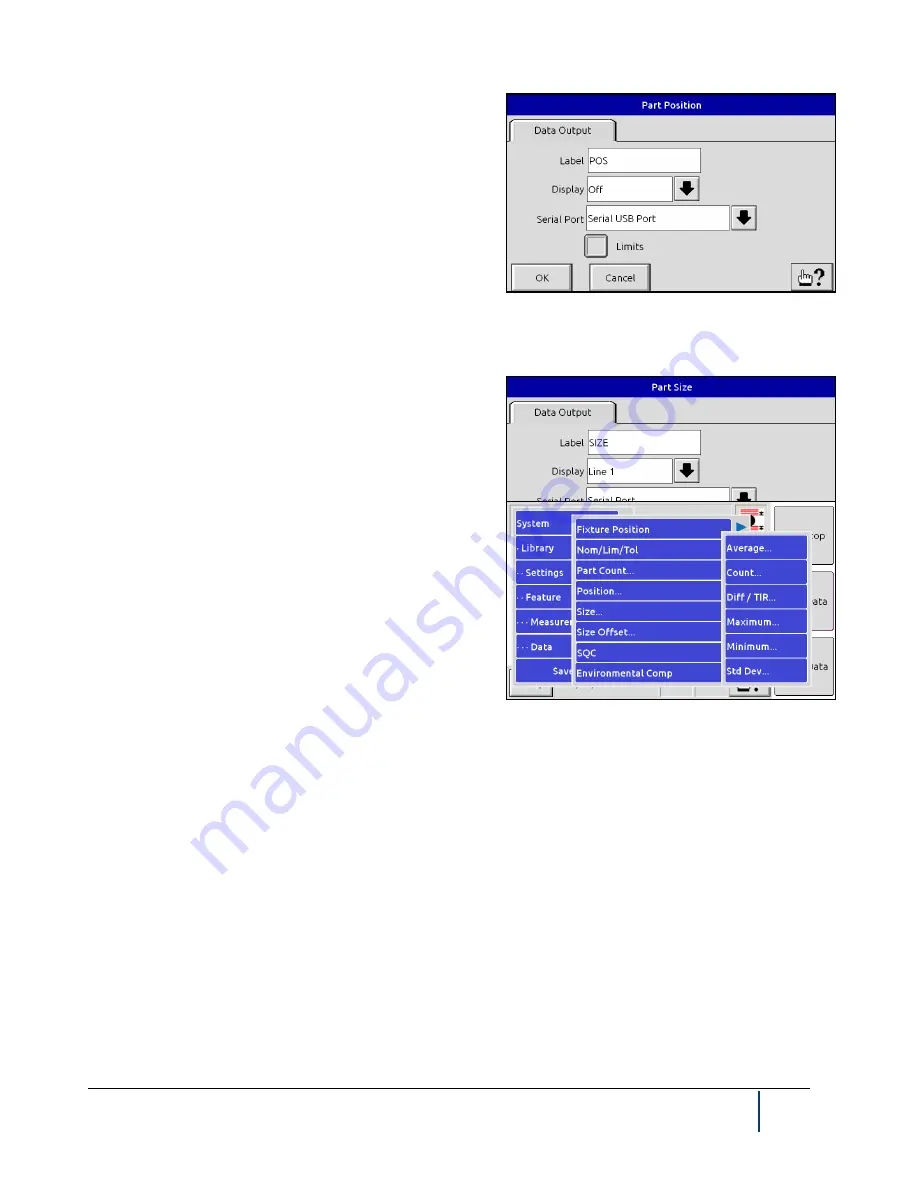

The

Part Position

displays the vertical part position. Part Po-

sition is the position of the part relative to the vertical center of

the scan. A positive value indicates that the part is above the

centerline, and a negative value indicates that the part is be-

low the centerline. Use this page to alter the title of this value

to something meaningful and relevant to your application, to

display or not display the position on the main measurement

display, and to transmit this value via the serial output port(s).

By default, the first line of data on the main measurement

display contains the

Part Size

(diameter measurement). This label can be changed from SIZE to any other alpha-

numeric character string by touching the SIZE box on this screen. This measurement can be moved to another

line or removed from the display. The Size value can also be

transmitted via the Serial Output port.

NOTE: With the Serial Output drop-down box, you can trans-

mit these data items via the serial or Ethernet port. To set up

for data transmission, see Settings -Serial Output Format and

System-Communication Ports for details.

Selecting the

SQC

command from the

Data

menu causes this

menu to be displayed.

These SQC values are computed:

•

Average

is the average Size reading, as computed

since the

last time data was cleared.

•

Count

is number of readings that have currently been

accumulated.

•

Maximum

is the largest Size reading detected since data was last cleared.

•

Minimum

is the smallest Size reading detected since data was last

cleared.

•

Diff/TIR

is difference between the Maximum value and the Minimum

value.

•

Standard Deviation

is the standard deviation of the mean from the Nominal.

•

Batch

is the group of readings used to compute the above SQC values.