Rockhopper 38 – Maintenance Manual

90

AP-74038, Rev. 1.1, 25/01/05

Step 3 :

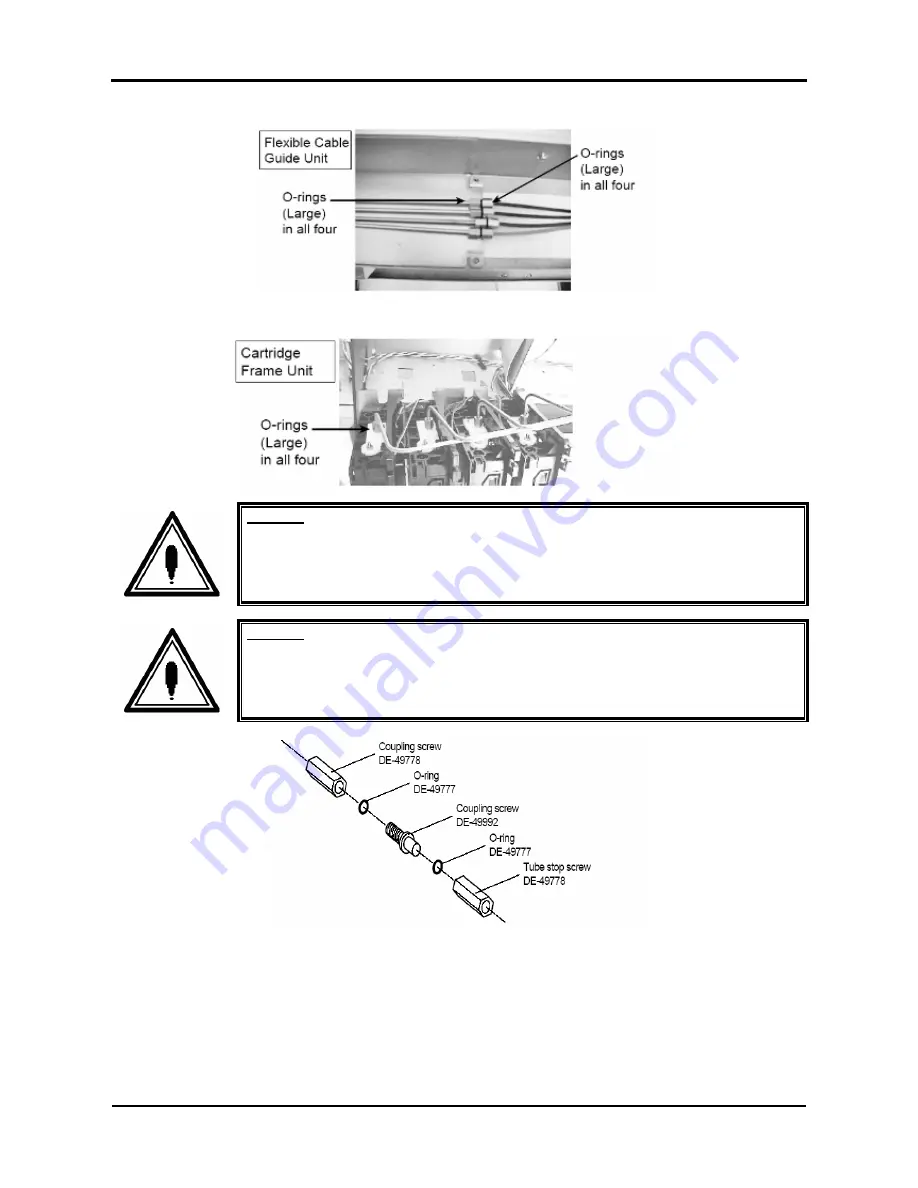

For replacement of Flexible Cable Guide Unit O-Rings, refer to…

Step 4 :

For replacement of Cartridge Frame Unit O-Rings, refer to…

Caution:

Be careful not to lose the O-rings, Initial filling and printing can not be done if the O-

rings are missing.

Caution:

Don’t use a tool to tighten the coupling screws but get them as tight as possible with

your fingers. If you use a tool, there is a risk of breaking the plastic taps.

Summary of Contents for Rockhopper 38

Page 1: ...Maintenance Manual MUTOH EUROPE N V AP 74038 Rev 1 1 25 01 2005 ...

Page 2: ...Rockhopper 38 Maintenance Manual 2 AP 74038 Rev 1 1 25 01 05 ...

Page 4: ...Rockhopper 38 Maintenance Manual 4 AP 74038 Rev 1 1 25 01 05 ...

Page 6: ...Rockhopper 38 Maintenance Manual 6 AP 74038 Rev 1 1 25 01 05 ...

Page 15: ...Rockhopper 38 Maintenance Manual 15 AP 74038 Rev 1 1 25 01 05 1 2 3 4 ...

Page 16: ...Rockhopper 38 Maintenance Manual 16 AP 74038 Rev 1 1 25 01 05 5 6 7 8 9 ...

Page 26: ...Rockhopper 38 Maintenance Manual 26 AP 74038 Rev 1 1 25 01 05 ...

Page 32: ...Rockhopper 38 Maintenance Manual 32 AP 74038 Rev 1 1 25 01 05 ...

Page 112: ...Rockhopper 38 Maintenance Manual 112 AP 74038 Rev 1 1 25 01 05 ...

Page 146: ...Rockhopper 38 Maintenance Manual 146 AP 74038 Rev 1 1 25 01 05 ...

Page 152: ...Rockhopper 38 Maintenance Manual 152 AP 74038 Rev 1 1 25 01 05 ...

Page 258: ...Rockhopper 38 Maintenance Manual 258 AP 74038 Rev 1 1 25 01 05 ...