12

13

Model C-SAW254T

1.

Each and every time make sure the circular saw is

switched off. If the red "O" button is engaged – the

device is off, if the green "1" button is engaged – the

device is on.

8

2.

Use knob (12) to set the height of the saw blade, or

cutting depth.

3.

Connect the device to a power source, use button

(15) to turn on. Wait a few seconds for the blade

to achieve its maximum speed. Position wood

workpiece on the worktable and begin cutting.

OVERLOAD BREAKER

The circular saw has overload protection. If the user

overloads the circular saw, the breaker turns off the saw

motor. Follow these steps if that happens:

1.

Wait at least a few minutes fort the device to cool

down.

2.

Press button (14) to reset the overload breaker.

3.

Press the green "1" button (15) to activate the

circular saw again.

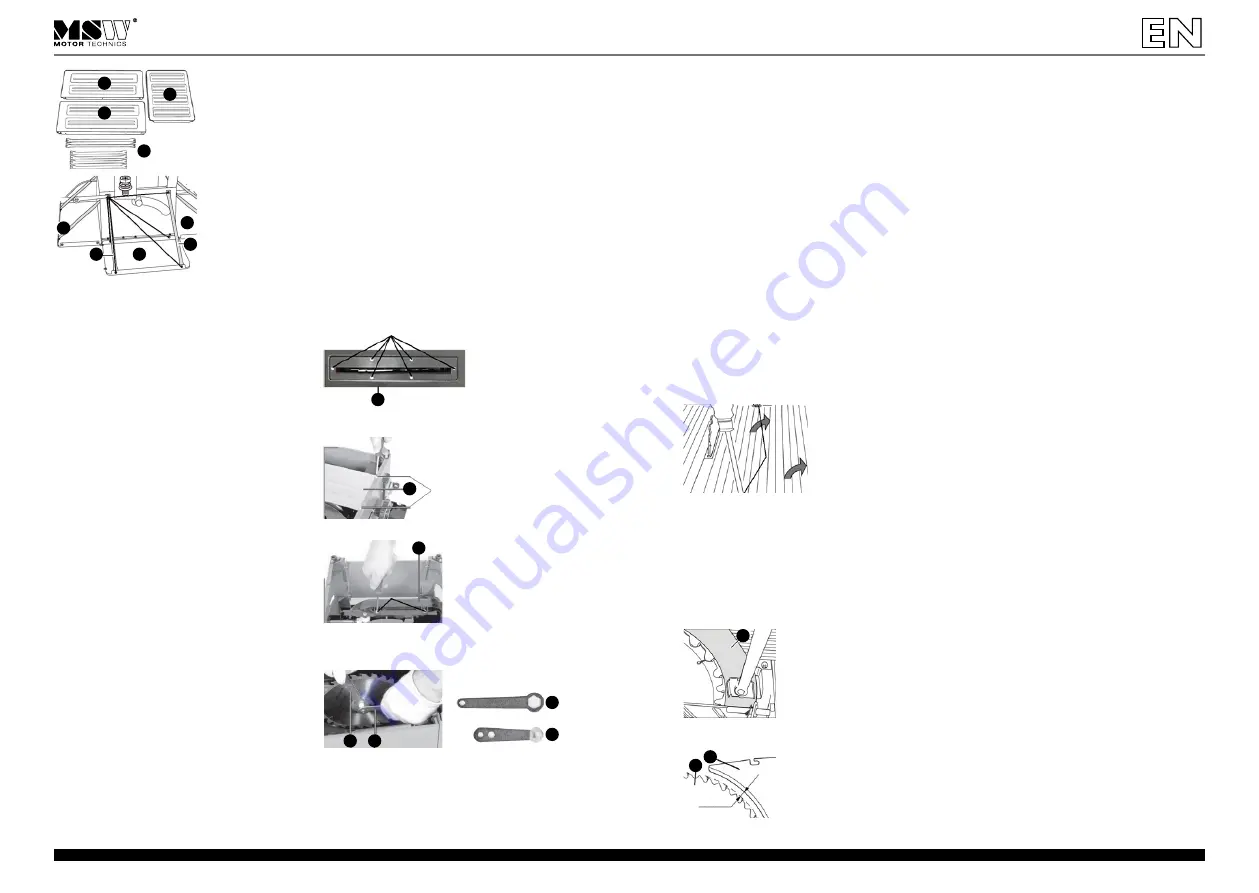

REPLACING THE SAW BLADE

1.

Remove blade guard (6) by reversing the steps for

assembling it.

2.

Use knob (12) to retract saw blade with the splitting

wedge.

3.

Unscrew and remove base insert (8).

11

11

5

2

11

11

2

2

5

•

Align the saw blade in the right position.

•

Use knob (17) to extract saw blade with the splitting

wedge.

•

Mount blade guard (7) by attaching it to the splitting

wedge (8) using a bolt in the guard.

•

Attach suction hose to the blade guard coupler (24).

•

Place the push stick (14) on the bracket (25) on the

right side.

•

Double check whether the saw blade is correctly

mounted, there is no play and that it does not rub on

other saw elements by gently spinning it with your

hand. Make sure that the saw rotation direction is

in accordance with the rotation direction shown on

the saw blade.

•

Always make sure that the saw blade and the

splitting wedge are in the same plane and that the

wedge edge is at the right distance (3-5 mm) away

from the saw blade teeth.

•

If possible, connect dust extraction to the other end

of the suction hose.

USE

Model C-SAW210

1.

Each and every time make sure the circular saw is

switched off. If the red "O" button is engaged – the

device is off, if the green "1" button is engaged – the

device is on.

LENGTHWISE CUTTING

a.

Set the parallel guide (9) in the desired position on

the worktable. Ensure it is parallel to the saw blade

(7). Lock it in place using two bolts (10).

b.

To use, push the workpiece against the guide (9) and

move it along the guide (9).

CUTTING AT AN ANGLE

a.

Place the guide (3) in the groove (2). Loosen the

guide knob (4), set the required cutting angle,

tighten the knob.

b.

To use, push the workpiece against the guide (3) and

move the guide along the groove (2).

c.

For crosswise 45 degree cutting use the cross guide

in the circular saw accessories. Mount it in the

parallel guide (9).

CUTTING WITH CHAMFERING

a)

Loosen the knob (13), set the tilt angle of the saw

blade (7), tighten the knob (7).

b) Cur according to the required cutting method, i.e.

lengthwise or crosswise.

4.

Turn the device "upside down" and unscrew the base

element number 20 shown on the diagram below.

5.

Unscrew guard (21) as shown below.

6.

Use two spanners to unscrew the saw blade. Use one

to keep the shaft in place and the other to remove

the nut.

7. Mount the new saw blade, then the removed

elements in reverse order to their disassembly.

20

21

1

2

1

2

3.

Use two spanners to unscrew the saw blade. Use one

to keep the shaft in place and the other (Allen key) to

remove the nut on the shaft. Remove the nut, flange

and the worn saw blade.

4. Mount the new saw blade, then the removed

elements in reverse order to their disassembly.

ALIGNING THE SPLITTING WEDGE

1.

Follow the first two steps of the saw blade

replacement instructions.

2.

Loosen the wedge mounting bolt.

3.

Align the wedge in its desired position, so that it is

3-5 mm away from the saw blade teeth.

LENGTHWISE CUTTING

a.

Set the parallel guide (10) in the desired position in

the worktable by moving it using the lever (12) along

the guide (3).

b.

To use, push the workpiece against the guide (10)

and move it along the guide.

CUTTING AT AN ANGLE

a.

Place the crosswise cutting guide (include in the

accessories) in the groove (4). Loosen the guide

knob, set the required cutting angle, tighten the

knob.

b.

To use, push the workpiece against the crosswise

cutting guide and move it along the groove (4).

CUTTING WITH CHAMFERING

a.

Loosen the knob (13), set the tilt angle of the saw

blade (9), tighten the knob (13).

b.

Cur according to the required cutting method, i.e.

lengthwise or crosswise.

2.

Use knob (17) to set the height of the saw blade, or

cutting depth.

3.

Connect the device to a power source, use button

"1" (1) to turn on. Wait a few seconds for the blade

to achieve its maximum speed. Position wood

workpiece on the worktable and begin cutting.

OVERLOAD BREAKER

1.

Remove blade guard (7).

2.

Remove the bolts on the worktable as shown on the

diagram below and remove the table top.

4.

Tighten the wedge mounting bolt. Attach the

worktable.

OVERLOAD BREAKER

The circular saw has overload protection. If the user

overloads the circular saw, the breaker turns off the saw

motor. Follow these steps if that happens:

1.

Wait at least a few minutes fort the device to cool

down.

2.

Press button (23) to reset the overload breaker.

3.

Press the green "1" button (1) to activate the circular

saw again.

GENERAL COMMENTS

•

After use, always turn off the circular saw by pressing

the red “0” button!

•

Only use saw blades with parameters specified in the

user manual

•

Do not use high speed steel (HS) saw blades!

•

Move the wood slowly and steadily in the direction

of the saw blade rotation.

•

Do not use blunt saw blades. This might result in

poor cut quality and the blade snagging.

•

Make sure the blade guard is always lowered and the

splitting wedge is in place when sawing.

•

Use the push stick for cutting narrow, small etc.

elements. When not using the push stick, place it in

the bracket.

•

Secure long pieces of wood against falling off the

circular saw after cutting.

•

If the blade snags during cutting, disconnect the

device from the power source and gently pull back

the workpiece.

•

Before sawing, inspect the workpiece for loose knots,

nails and metal elements. If discovered, remove

before commencing cutting.

•

After use clean dust, chips and shavings from the

device.

•

To move the device, only hold by the worktable. To

not attempt to hold the guards, blade, guides etc.

TRANSPORTATION AND STORAGE

Shaking, crashing and turning upside down of the device

should be prevented when transporting it. Store it in

a properly ventilated location with dry air and without any

corrosive gas.

CLEANING AND MAINTENANCE

•

Before cleaning you must remove the electricity

supply plug isolating the appliance from the main

power circuit.

•

Always clean the device after use.

•

Use cleaner without corrosive substances to clean

surface..

•

Do not wipe plastic parts with solvent. Solvents such

as gasoline, thinner, benzene, alcohol, ammonia and

oil may damage and crack plastic parts. Do not wipe

them with such solvents.

•

Wipe plastic parts with a soft cloth lightly dampened

with soapy water.

•

Remove dusts, shavings from the vents and motor

housing using a soft cloth and purge with low

pressure air.

ATTENTION! Do not submerge the device in water!

8

8

7

max. 3-5mm

Rev. 10.10.2017

Rev. 10.10.2017