Form 801680

Page Number - 5

static Pressure test (engine off)

For diagnosing:

Cooling system leaks

set-up & Procedure:

1. Ensure the cooling system is cool and not pressurized.

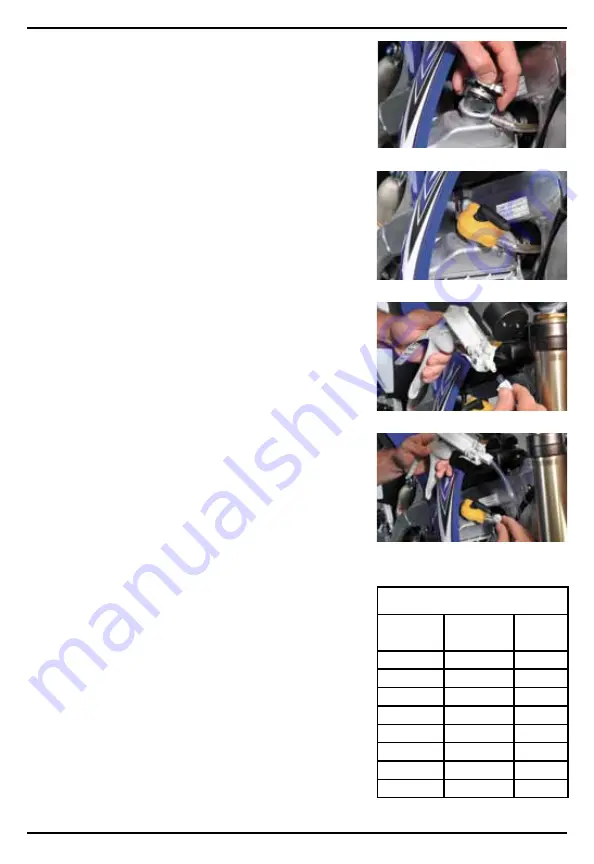

Carefully remove the radiator or coolant bottle pressure cap

(Fig. 1).

2. Check to see that the radiator or coolant bottle is filled to

the proper level, and check hoses for visual damage or

leaks. Fill and repair as necessary prior to testing.

3. Apply water or coolant to the rubber gasket of cooling

system test adapter, and install it in place of the

pressure cap (Fig. 2).

4. Secure one end of the clear hose to the pressure pump

using the compression nut (Fig. 3).

5. Secure the second end of the hose to the cooling system

test adapter using the compression nut (Fig. 4).

6. Note the operating pressure of the cooling system

indicated on the cap or in the vehicle repair manual.

7. Operate the pressure pump until the needle on the

pressure gauge moves to the high end of the colored band

indicating the appropriate pressure range of the cap (see

Chart A).

caUtion: Do not pressurize the cooling system beyond

the appropriate color of band for the system being tested.

8. Monitor the gauge for at least two minutes. If the pressure

reading drops, a leak is present.

9. With the system still pressurized, perform a visual

inspection of the entire cooling system. Check hoses

and connections for seepage, which would indicate a leak.

Return to the gauge and check the reading once more.

10. Most leaks are external, and visible seepage occurs.

However, a drop in pressure with no visible leakage can

indicate a blown head gasket or cracked block, where fluid

leaks into the combustion chamber. Visually inspect oil

and transmission fluid for signs of coolant. Proceed to the

Dynamic Pressure Test for better methods of diagnosing

internal leaks.

11. When testing is complete, release the pressure in the

system by pressing the pressure relief valve located on the

pump hose near the quick-connect couple.

12. Repair leaks if necessary, and retest.

13. Disconnect components, clean and store them properly.

14. Refill the radiator or coolant bottle to the proper level, and

replace the cap.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

chart a:

cooling system cap Pressure test ranges

Rated

Pressure (PSI)

Pressure Range

(PSI)

Arrow/Band

Color

4

3 - 5

Yellow

7

6 - 8

Green

10

9 - 11

White

13 or 14

12 - 16

Blue

15 or 16

14 - 18

Yellow

18

16 - 20

Black

20

18 - 22

Green

30

28 - 30

Red