Wall formwork

Mammut 350

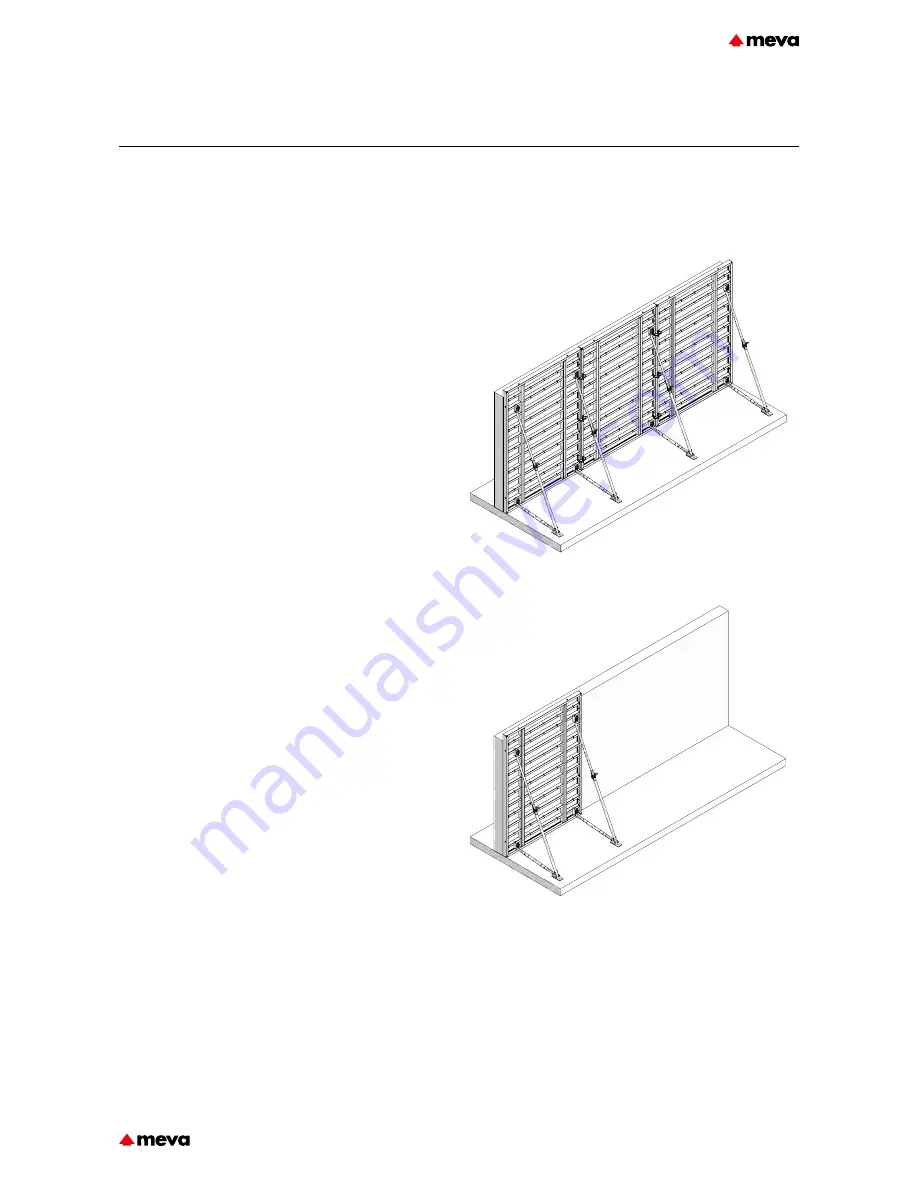

Fig. 65.1

Fig. 65.2

Formwork assembly and stripping

Stripping

Do not start stripping before the

concrete has set to the point

where it can no longer deform.

It is best to start stripping at the

stop ends or at a short corner.

Start stripping with the inside

formwork. Stripping of both the

outside and inside formwork is

performed as follows:

1. Remove the working scaffold.

2. Remove the articulated flange

nuts and tie rods section by

section. Make sure the unbraced

formwork is immediately secured

to prevent it falling over or strip

it immediately.

3. On the formwork panels or

large panel units the assembly

locks are removed at the joints,

and the panels or panel units

are then lifted out by hand or

by crane. Before transporting by

crane, the formwork must be

detached from the concrete!

4. Clean the facing and remove

any concrete. Before the next

use, spray the facing with the

release agent MevaTrenn FT8

(for alkus facings). Observe the

operating instructions for the

alkus facing.

Note

The release agent must not be

stored in galvanized containers.

Please note

When stripping manually, detach

and disassemble the working

scaffold and the brace frames

before stripping the panels.

When transporting large panel

units with a crane, the work-

ing scaffold and wall braces are

moved together with the panel

units. While vertical, all compo-

nents are cleaned and sprayed

with release agent before being

lifted together to the next cycle

(see pages M350-51 and

52).

If there is no further use for the

panel units, the working scaffold

and wall braces are detached

and disassembled in a horizon-

tal position, and cleaned and

stacked for transport.

M350-65

Technical Instruction Manual / Status November 2018