55

E

TROUBLESHOOTING, DIAGNOSTICS, AND MAINTENANCE

mAiNTENANCE

CONTINUED

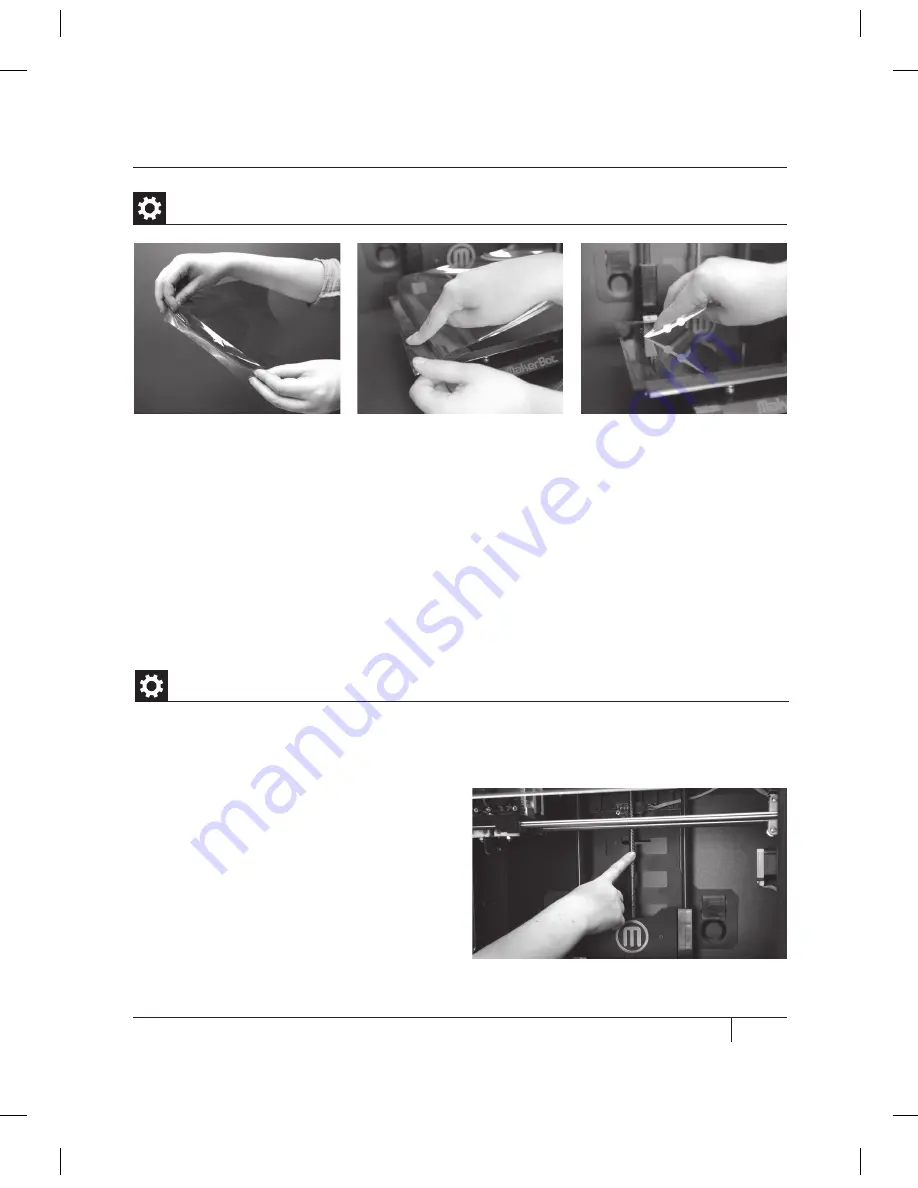

4. Peel off the plastic backing bit by bit, smoothing the newly exposed kapton tape as you

go. Use the tape applicator from the MakerBot Replicator 2X package to remove bubbles.

If you don’t have the tape applicator, use a credit card to remove bubbles.

5. Continue smoothing the tape down bit by bit until you have covered the entire plate.

If there are still bubbles under the kapton tape, lift the edge of the tape that is nearest

to the bubbles and use the tape applicator to smooth the tape from the center out.

6. When the kapton tape is applied as smoothly as possible, trim the edges of the sheet or fold

them over the sides of the build plate.

Applying Kapton Tape | Continued

After approximately 50 hours of build time, you should lubricate the threaded rod on your

Z-axis and the X-axis idler pulley. To lubricate the threaded rod and the idler pulley:

1. Find the tube of PTFE-based grease from

the MakerBot Replicator 2X package.

2. Grasp both sides of the build platform

and push it gently to the bottom of the

MakerBot Replicator 2X.

3. Use a clean, lint-free rag [or your finger]

to spread the PTFE-based grease onto the

top section of the threaded rod.

Lubricating the Threaded Rod and the X-Axis Idler Pulley

Summary of Contents for Replicator 2X

Page 1: ...USER MANUAL DUAL EXTRUSION...

Page 2: ......

Page 4: ...Welcome Let s get started A...

Page 8: ...Setting Up Your MakerBot Replicator 2X Experimental 3D Printer B...

Page 20: ...Startup Process Leveling Loading Testing C...

Page 35: ...35 NOTES C Startup PROCESS leveling loading testing...

Page 36: ...Making an Object with MakerBot MakerWare D...

Page 46: ...E Troubleshooting Diagnostics and Maintenance...

Page 64: ...MakerBot One MetroTech Center 21st Floor Brooklyn NY support makerbot com makerbot com...