56

E

TROUBLESHOOTING, DIAGNOSTICS, AND MAINTENANCE

mAiNTENANCE

CONTINUED

8. Squeeze a small amount of the PTFE-

based grease directly onto the exposed

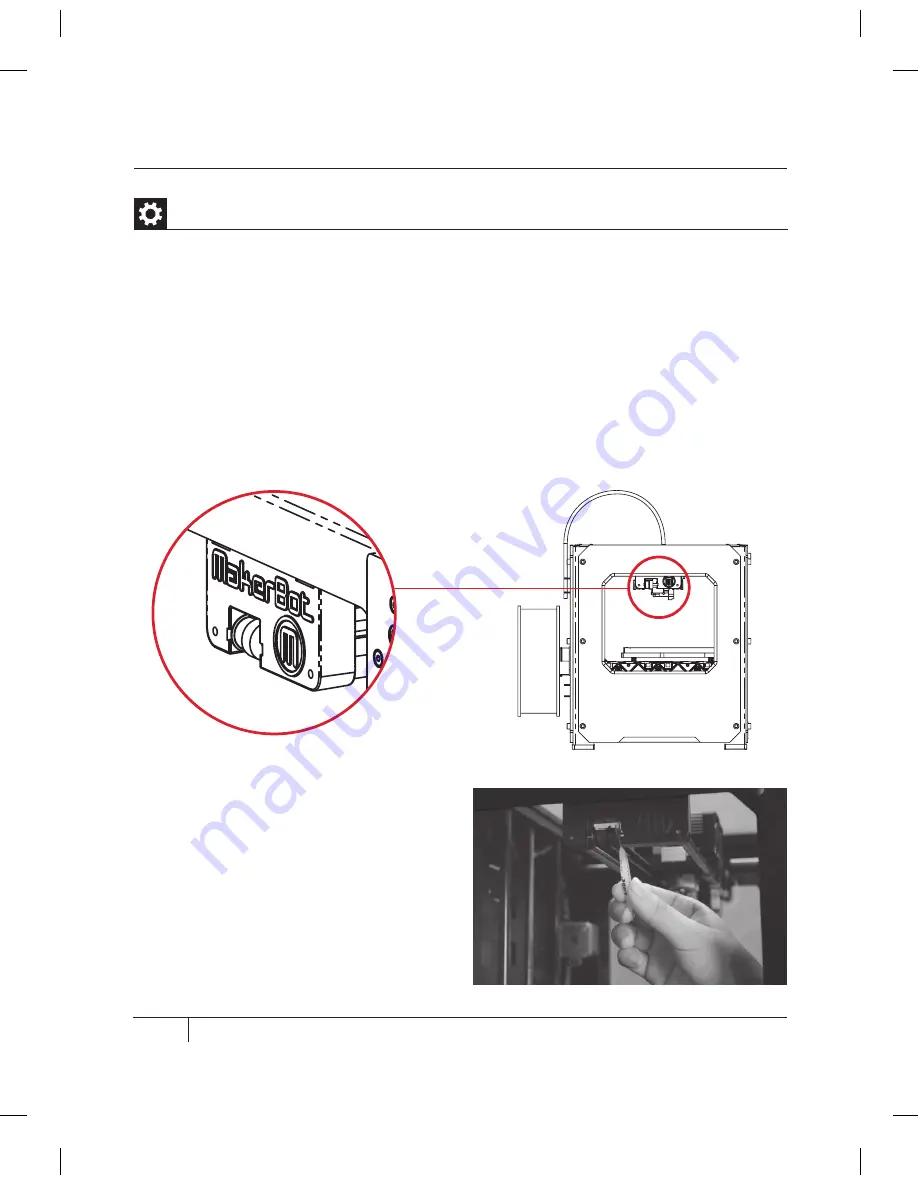

area of the dowel inside the idler pulley

and manually move the pulley back and

forth to spread the grease.

Lubricating the Threaded Rod and the X-Axis Idler Pulley

4. Make sure you get the grease inside the threads themselves.

5. Grasp both sides of the build platform and move it to the top of the MakerBot Replicator 2X.

6. Use a clean, lint-free rag [or your finger] to spread the PTFE-based grease onto the bottom

section of the threaded rod. Make sure you get the grease inside the threads themselves.

7. Locate the X-axis idler pulley. If you are facing the front of the MakerBot Replicator 2X,

the idler pulley is at the top left side. The idler pulley is one of the pulleys that allow the rubber

belt to move the extruder from left to right, or along the X-axis. The pulley at the other side of

the gantry is called the timing pulley and does not require lubrication.

Summary of Contents for Replicator 2X

Page 1: ...USER MANUAL DUAL EXTRUSION...

Page 2: ......

Page 4: ...Welcome Let s get started A...

Page 8: ...Setting Up Your MakerBot Replicator 2X Experimental 3D Printer B...

Page 20: ...Startup Process Leveling Loading Testing C...

Page 35: ...35 NOTES C Startup PROCESS leveling loading testing...

Page 36: ...Making an Object with MakerBot MakerWare D...

Page 46: ...E Troubleshooting Diagnostics and Maintenance...

Page 64: ...MakerBot One MetroTech Center 21st Floor Brooklyn NY support makerbot com makerbot com...