a sensor at the exact same location. For example do not attempt to calibrate a ceiling mounted temperature sensor by measuring air temperature near the

floor. The calibration may be off by ten (10) degrees or more.

Sensor Calibration Procedure

To calibrate a sensor:

1. From the Configuration and Diagnostics menu, select Calibrate Sensors.

2. Select the desired sensor to display its calibration settings.

3. Type in the new, accurate reading in the Enter Correct Value setpoint and then select Save Changes.

The Span and Offset adjustments are automatically recalculated and permanently saved to the Agility unit. Span describes the pre-programmed range in

proportion to the electrical signal (typically 4-20ma). Offset defines the "starting point" by comparing the minimum range value with the electrical

signal. Because both factors are dynamically adjusted, calibration is most effective when the sensor is close to either extreme of its sensing range, i.e. calibrate a

0 - 300 PSIG pressure sensor when the pressure is at or near 0 PSIG then again at or near 300 PSIG.

Analog Output Troubleshooting

The Agility Controller’s two analog outputs generate an active 4-20mA signal to control variable speed or position devices including modulating valves and

variable speed motors. Since the Agility Controller

actively

generates the control signal, no other source of power should be connected to the current loop.

Additionally, each 4-20mA current loop is optically isolated to eliminate troublesome ground loop conditions.

The surest method to determine if the analog output is functional is to entirely remove the field wiring from the pair of analog output terminals and, using a high

quality digital DC milliamp meter, directly measure the signal. A reading between 4mA and 20mA indicates a functional analog output.

Digital Output Troubleshooting

Digital Outputs are solid state relays driven by an isolated low voltage signal from the Agility microcontroller. Some sections also apply to a faulty Input module.

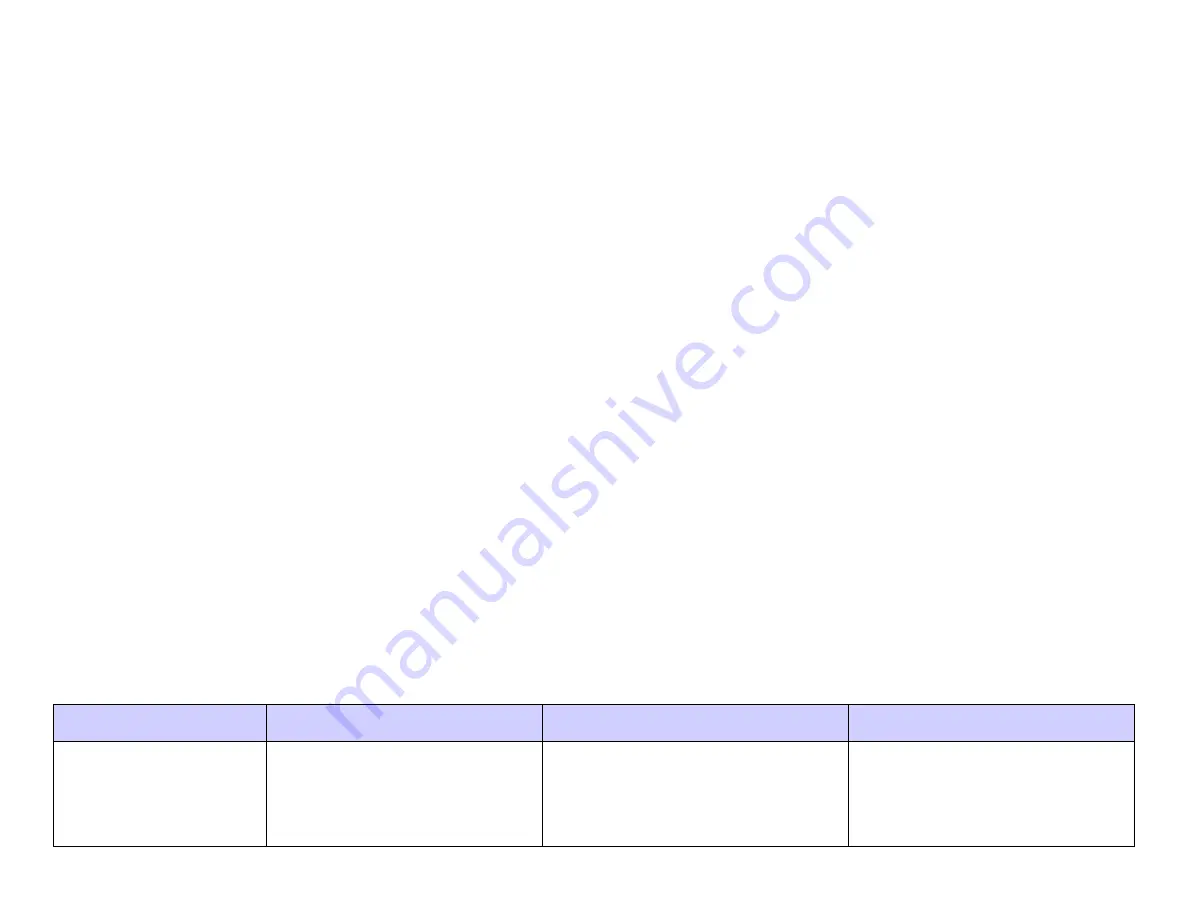

Problem

Test

Possible Solution

Comments

Digital Output fails

to energize.

Verify that the microcontroller is

trying to energize the output by

viewing View I/O Status.

Enable (or disable) the control

mechanism that energizes the

output.

Some outputs, such as suction

pilot valves or compressor

unloaders may be energized when

the control routine is off ("Reverse

Logic").