Appendix C: Theory of operation

Paper path and transport components

For an image to be printed, the paper or specialty media has to be moved from an input source, such as a tray,

into the printer and eventually exit into an output source.

The most important component in this process is the paper. Old, damaged, or out-of-specification paper can

and will cause feed and transport problems. If you encounter problems, you should always check the paper

first. See

“Paper and specialty media guide” on page 26

. In addition, it is always good practice to check the

printer and driver settings to see if the paper being used matches the user settings. It is not uncommon to find

a user printing on cardstock with the printer programmed to print on a plain paper setting.

The printer feed and transport components can fail and cause paper jams or other feed and transport problems.

These components should be examined for damage or wear and replaced if necessary.

Tray section

Paper size and detection

The paper size is only detected based on the setting of the length guide. The width guides do not provide

paper size information to the printer. The length guide can be adjusted to accommodate different paper sizes

by moving it to the front or rear of the tray. The length guide should come into contact with the paper and hold

it in position. The width guide is designed so that it can adjust to the paper width by moving the guide to the

left or right. Both paper guides can be locked to position.

The sensor (550-sheet tray empty) detects paper and the sensor (550-sheet tray paper size) detects the size

of paper supplied from each tray assembly. A system of four switches is used to decode the paper size, which

is then sent to the controller board.

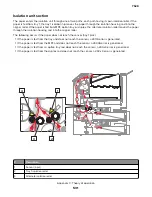

Paper lift

The sensor (pick roller position) determines if the lift plate in the paper tray is at the optimum position for paper

to be properly picked. As paper is fed out, clearance occurs between the paper and the pick rollers. When the

sensor determines the specified amount of clearance, the lift plate is raised to position the paper in the optimum

position to be picked properly.

Paper pick

The pick roller assembly is a mechanical unit supplying paper from the tray to the paper path. Three motors

move the paper from the tray to the transfer module at the second transfer station. The motor (isolation) feeds

the paper from the pick system to the alignment rollers. The leading edge of the paper is aligned to the alignment

rollers and then fed into the transfer nip.

The system is timed so that the image is formed and the page is picked to allow the image to be correctly

placed on the paper. The sensor (550-sheet tray empty) detects if there is paper present in the tray. If paper is

present, the media feeder drives the pick roller which moves the paper from the tray to the isolation unit.

7528

Appendix C: Theory of operation

529

Summary of Contents for XC4150

Page 34: ...7528 34 ...

Page 276: ...7528 276 ...

Page 294: ...Scan SE Scanner Info 7528 Service menus 294 ...

Page 317: ...3 Remove the screw B from the lower left side of the cover B 7528 Repair information 317 ...

Page 320: ...3 Remove the three screws A 7528 Repair information 320 ...

Page 327: ...3 Remove the E clip B 4 Remove the E clip C 7528 Repair information 327 ...

Page 358: ...5 Remove the two screws D from under the gear box 7528 Repair information 358 ...

Page 360: ...3 Disconnect the cable A from the LVPS 7528 Repair information 360 ...

Page 370: ...3 Disconnect the motor cable A A 7528 Repair information 370 ...

Page 371: ...4 Remove the four screws B and then remove the motor B 7528 Repair information 371 ...

Page 374: ...4 Disconnect the cable B 5 Remove the screw C securing the HVPS C 7528 Repair information 374 ...

Page 400: ...14 Remove the clip M and then remove the spacer 7528 Repair information 400 ...

Page 403: ...7528 Repair information 403 ...

Page 414: ...5 Remove the screw C from the printhead 7528 Repair information 414 ...

Page 429: ...8 Route the ADF cable through the flatbed 9 Remove the ADF 7528 Repair information 429 ...

Page 437: ...7 Disconnect the two cables B on the controller board 7528 Repair information 437 ...

Page 443: ...5 Remove the screw D and then remove the scanner tilt D 7528 Repair information 443 ...

Page 478: ...7528 478 ...

Page 485: ...7528 485 ...

Page 487: ...Assembly 1 Covers 1 2 4 6 7 8 9 1 14 10 3 5 13 13 11 11 12 7528 Parts catalog 487 ...

Page 489: ...Assembly 2 Covers 2 14 7528 Parts catalog 489 ...

Page 491: ...Assembly 3 Control panel 5 4 3 2 1 7528 Parts catalog 491 ...

Page 493: ...Assembly 4 ADF and flatbed 1 3 11 10 4 9 5 6 7 8 2 7528 Parts catalog 493 ...

Page 495: ...Assembly 5 Fuser 1 7528 Parts catalog 495 ...

Page 497: ...Assembly 6 Transfer module 1 2 7528 Parts catalog 497 ...

Page 499: ...Assembly 7 Paper feed 8 2 1 2 4 7 3 5 5 6 7528 Parts catalog 499 ...

Page 501: ...Assembly 8 Paper path 1 8 6 2 3 1 10 5 7 9 4 7528 Parts catalog 501 ...

Page 503: ...Assembly 9 Paper path 2 1 4 2 5 10 3 6 9 7 8 7528 Parts catalog 503 ...

Page 505: ...Assembly 10 Duplex 9 8 3 3 7 6 1 1 2 4 5 7528 Parts catalog 505 ...

Page 507: ...Assembly 11 Electrical 16 2 3 4 5 7 8 9 11 12 13 15 6 1 14 10 7528 Parts catalog 507 ...

Page 510: ...7528 Parts catalog 510 ...

Page 511: ...Assembly 12 550 sheet tray option 1 2 1 7528 Parts catalog 511 ...

Page 513: ...Assembly 13 550 sheet tray option 2 1 2 3 4 12 11 6 13 5 9 10 7 8 7528 Parts catalog 513 ...

Page 515: ...Assembly 14 Adjustable stand 2 2 3 3 1 7528 Parts catalog 515 ...

Page 518: ...7528 Parts catalog 518 ...

Page 520: ...7528 520 ...

Page 527: ...3 Apply the changes 7528 Appendix B Options and features 527 ...

Page 528: ...7528 528 ...

Page 554: ...7528 554 ...

Page 568: ...7528 Part number index 568 ...

Page 574: ...7528 Part name index 574 ...