LAGUNA

TOOLS

27

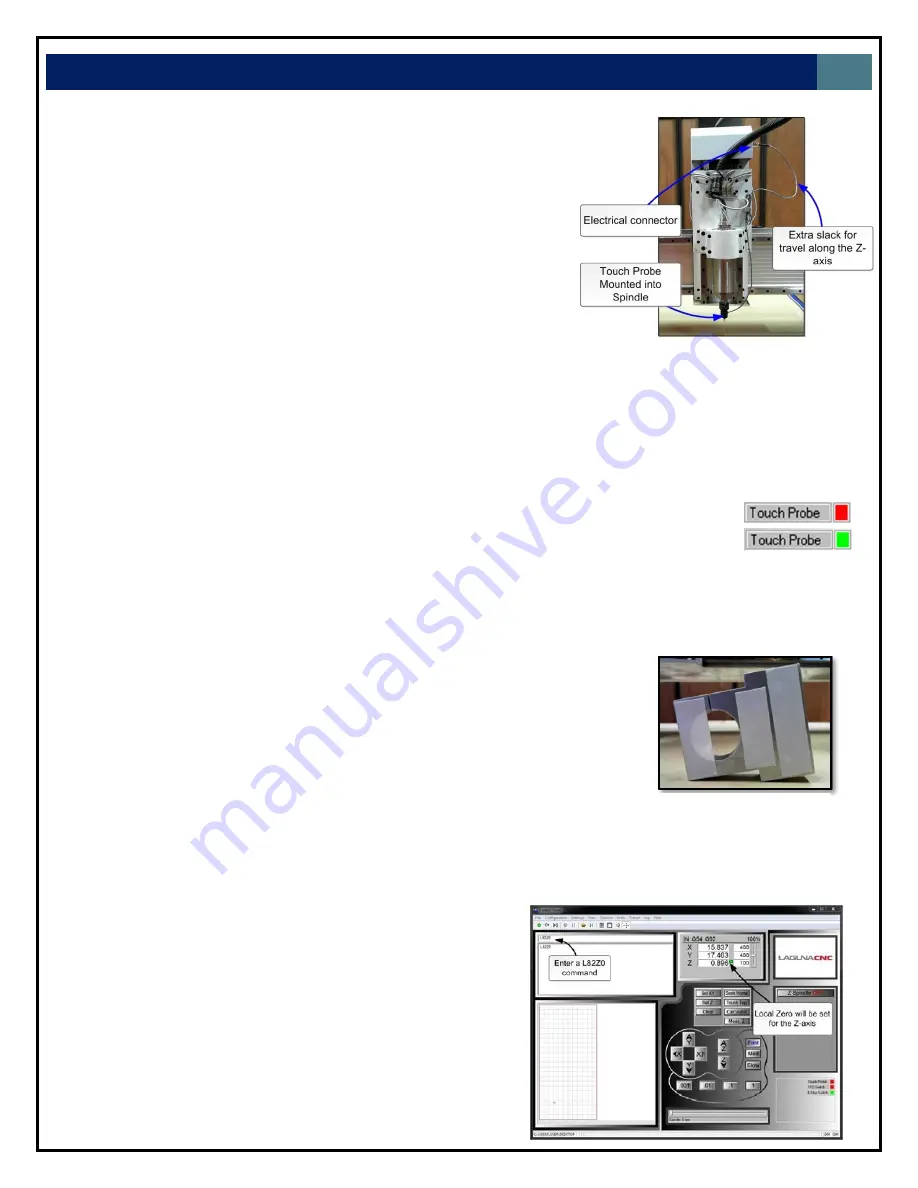

1.

Mount

touch

probe

into

the

spindle.

1.1

Using

a

suitable

collect

(3/8")

and

clamping

nut(ER20

‐

A

‐

W).

1.2

Fasten

the

touch

probe’s

connector

into

the

connector

on

the

gantry.

1.3

Bundle

the

touch

probe's

wire

and

secure

it

into

the

clip

located

on

the

spindle

mounting

plate.

Leave

extra

slack

between

the

clip

and

connector

to

allow

for

travel

along

the

Z

‐

axis.

2.

Verify

that

the

touch

probe

is

working

properly

before

proceeding

to

prevent

damage

to

the

probe.

2.1

Manually

activate

the

touch

probe

and

verify

that

the

touch

probe

indicator

in

your

winCNC

controller

changes

state

from

Red

to

Green,

as

seen

to

the

right

2.2

If

touch

probe

indicator

does

not

change

state,

do

not

proceed

until

fault

is

corrected.

3.

Fasten

the

part

to

be

scanned

to

the

spoil

board.

3.1

This

can

be

done

by

using

double

‐

sided

tape

or

vacuum

if

your

machine

is

equipped

with

a

vacuum

table.

3.2

For

demonstration

purposes,

the

sample

part

seen

to

the

right

will

be

used

throughout

this

walkthrough.

4.

Enter

the

L82Z0

command

in

the

command

window

4.1

Position

the

touch

probe

such

that

it

can

travel

in

the

negative

Z

‐

direction

and

touch

off

on

what

will

be

the

Z

‐

Zero

plane.

Normally

this

is

the

material

the

object

is

mounted

to.

4.2

The

L82Z0

command

measures

the

surface

with

the

probe

and

sets

the

measured

point

to

be

the

Z0

‐

plane.

Note:

This

step

is

not

required

to

execute

a

3D

‐

scan

but

it

will

correctly

establish

the

Z

Zero

Plane

for

rendering

in

CAD

software.

Otherwise

the

Z

Zero

plane

will

need

to

be

adjusted

in

CAD

software.

Figure

34.

Touch

probe

mounting

Figure

35.

Fastening

a

part

using

double

sided

tape

Figure

36.

(Right)

Controller

screen

shot

after

execution

of

a

L82Z0

command

Summary of Contents for CNC Swift Series

Page 54: ...LAGUNA TOOLS 54 SPECIFICATIONS...