LAGUNA

TOOLS

22

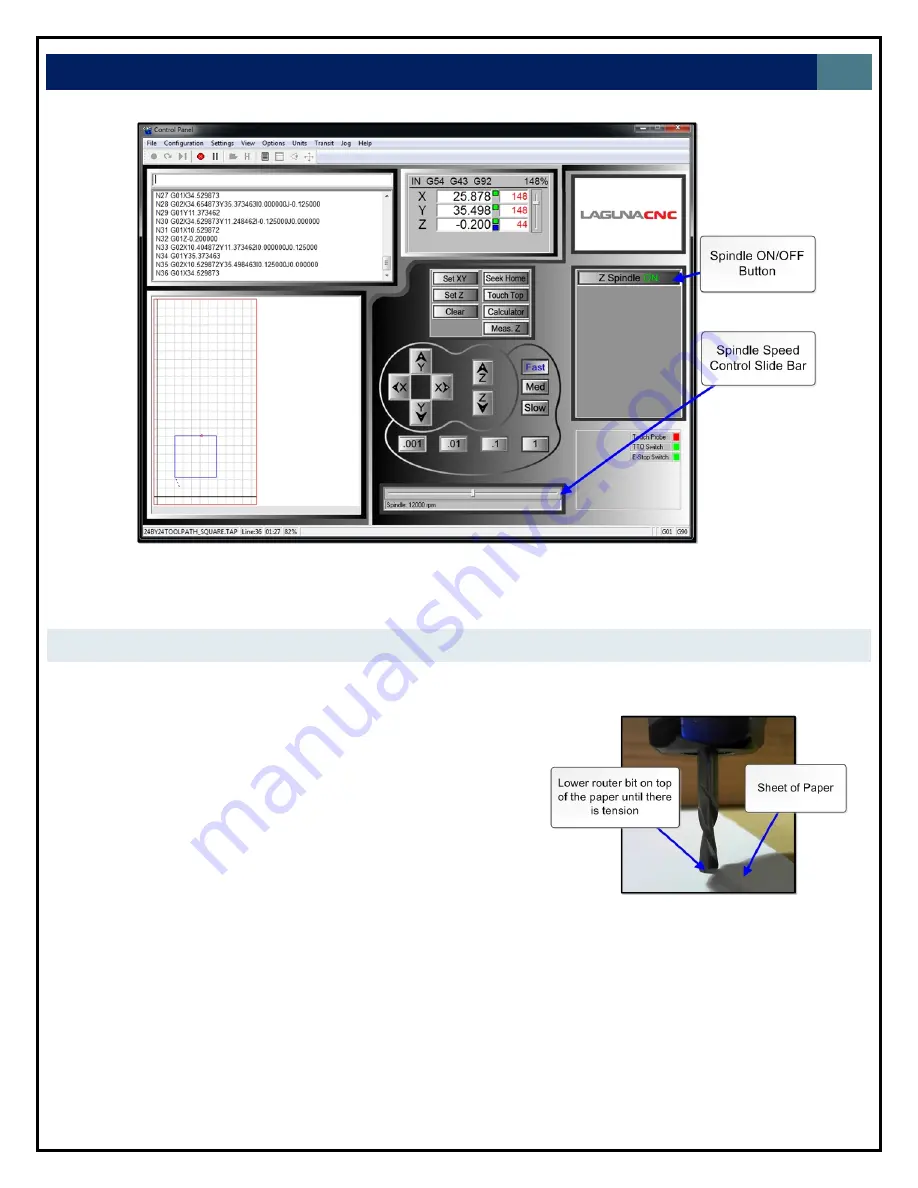

Figure

21.

Controller

interface

spindle

controls

MEASURING

TOOL

LENGTH

(TOUCH

TOP

BUTTON)

Measuring

tool

length

is

a

necessary

step

prior

to

cutting.

It

establishes

the

correct

Z

zero

plane

in

the

work

space

coordinate

system.

1.

Manual

Method

1.1

Mount

the

tool

in

the

spindle

1.2

Bring

the

tool

over

the

material

that

will

serve

as

the

Z0

plane

for

the

application.

1.3

Using

the

slow

transit

speed

setting,

lower

the

spindle

down

close

to

the

table.

1.4

Slide

a

sheet

of

paper

under

the

tool.

1.5

Lower

the

tool

down

using

the

0.001

or

0.01

incremental

transit

setting

until

there

is

tension

on

the

paper

but

enough

clearance

to

slide

the

sheet

of

paper

out.

1.6

Press

the

“SetZ”

button

in

the

control

interface.

1.6.1

A

green

box

will

appear

next

to

the

Z

coordinate

in

the

access

window.

Figure

22.

Paper

test

for

measuring

tool

length

manually

Summary of Contents for CNC Swift Series

Page 54: ...LAGUNA TOOLS 54 SPECIFICATIONS...