Page 34

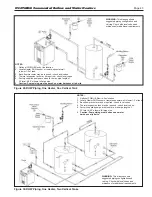

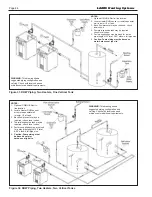

This unit’s efficiency is higher with lower return

water temperatures.

Therefore, to get the most of low

return temperature with multiple boilers, pipe as shown in

Figure 22 through Figure 28

All boiler models can be ordered with a pump. When

the pump is included with the boiler, the boiler must be

located within 15 feet (4.6m) of the supply/return header

(or hydraulic separator). These units must be piped in

a primary-secondary fashion, such that the pump that

is included only serves the boiler. The pumps are sized

for the headloss of the boiler and a maximum of 30 feet

(9.1m) of piping that is the same size as the boiler water

connections See Table 15.

If longer pipe lengths or alternate piping methods are

being used, the pump must be sized for the boiler

and the piping it will serve. Table 13 on page 32

shows water flow and headloss data for the boiler. The

manufacturer strongly recommends primary-secondary

piping.

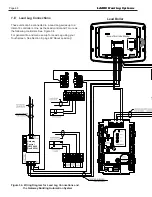

6.A.2

Boiler Cold Water Make-Up

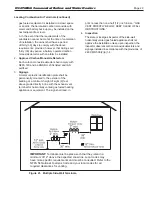

1. Connect the cold water supply to the inlet

connection of an automatic fill valve.

2. Install a suitable back flow preventer between the

automatic fill valve and the cold water supply.

3. Install shut off valves where required.

The boiler piping system of a hot water heating boiler

connected to heating coils located in air handling

appliances where they may be exposed to refrigerated

air circulation must be equipped with flow control valves

or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle.

A boiler installed above radiation level, or as required by

the authority having jurisdiction, must be provided with a

low water cutoff device either as a part of the boiler or at

the time of boiler installation.

6.A.3

Condensate Drain

A condensate drain trap is built into the unit.

No additional or secondary trap is required. .

BOILER

PIPE SIZE,

HEATER

PIPE SIZE,

SIZE

INCHES

SIZE INCHES

-

-

150

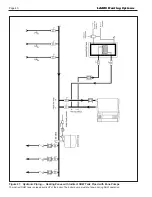

1¼

-

-

199

1¼

-

-

285

2

399

1¼

399

2

500

1½

500

2

600

1½

600

2

750

2

750

2

850

2

850

2

Table 15.

Water Connection Pipe Sizes

SECTION 6

WATER CONNECTIONS - Part A

Section 6 is divided into two parts. Section

6A covers Boiler units designed for hydronic

heating. Section 6B covers Heater models,

which are designed exclusively for “volume

water” domestic hot water applications. Refer

to the proper section for instructions on

installing and piping your product. Refer to

Table 9 for the connection pipe sizes required.

6.A Boiler

6.A.1

Boiler Water Piping -

NOTE:

This appliance must be installed in a closed

pressure system with a minimum of 12 psi (82.7kPa)

static pressure at the boiler.

Water piping should be supported by suitable hangers or

floor stands. Do not support piping with this appliance.

Due to expansion and contraction of copper pipe,

consideration should be given to the type of hangers

used. Rigid hangers may transmit noise through the

system resulting from the piping sliding in the hangers.

It is recommended that padding be used when rigid

hangers are installed. Maintain 1” (2.5cm) clearance to

combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size) to a drain

or in a manner to prevent injury in the event of pressure

relief. Install an air purger, an air vent, a diaphragm-type

expansion tank, and a hydronic flow check in the system

supply loop. Minimum fill pressure must be 12psig

(82.7kPa). Install shutoff valves where required by code.

LAARS Heating Systems

Summary of Contents for Neotherm NTH

Page 4: ...LAARS Heating Systems...

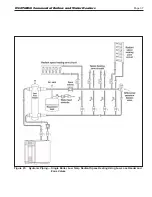

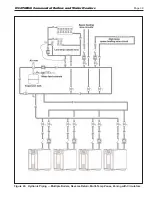

Page 36: ...Page 36 Figure 22 Hydronic Piping Single Boiler Zoning with Circulators LAARS Heating Systems...

Page 52: ...Page 52 Figure 36 Ladder Diagram 7 H Ladder Diagram LAARS Heating Systems...

Page 100: ...Page 100 Parts Illustration 4 Internal Components Sizes 750 850 LAARS Heating Systems...

Page 102: ...Page 102 Parts Illustration 6 Gas Train Components Sizes 600 850 LAARS Heating Systems...