Page 31

SECTION 4

GAS SUPPLY AND PIPING

All Installations must conform to the National Fuel

Gas Code ANSI Z223.1/NFPA54, and/or local codes.

In Canada, the installation must conform to the latest

edition of CSA B149.1 Natural Gas and Propane

Gas Installation Code, and/or local codes. Gas piping

should be supported by suitable hangers or floor

stands, not the appliance.

Review the following instructions before proceeding

with the installation.

1. Verify that the appliance is fitted for the proper type of

gas by checking the rating plate. The unit will function

properly without the use of high altitude modification

at elevations up to 10,000 feet (3050 m).

2. Verify that the Min and Max inlet gas supply

pressures are within the parameters shown in

Table 8.

3. Refer to Table 9 to size the piping.

4. Run gas supply line in accordance with all

applicable codes.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of the

gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of liquefied

petroleum gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45kPa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less

than 1/2 PSIG (3.45kPa).

10. The appliance and its gas connection must be leak

tested before placing it in operation.

11. Purge all air from gas lines.

Notes:

Consult and confirm with Applicable Fuel Gas Code before

beginning work. Verify gas inlet pressure is correct using

Table 8 before starting boiler.

NOTE

: This appliance and all other gas appliances

sharing the gas supply line must be firing at maximum

capacity to properly measure the inlet supply pressure.

The pressure can be measured at the supply pressure

port on the gas valve. Low gas pressure could be an

indication of an undersized gas meter, undersized

gas supply lines and/or an obstructed gas supply

line. Some units are equipped with low and high gas

pressure switches that are integrally vent limited.

These types of devices do not require venting to

atmosphere.

WARNING

If an inline high gas pressure regulator is used, it MUST

BE of the lockup type and located a minimum of 10 feet

from the unit. Failure to do so may result in insufficient

gas volume supplied to the unit.

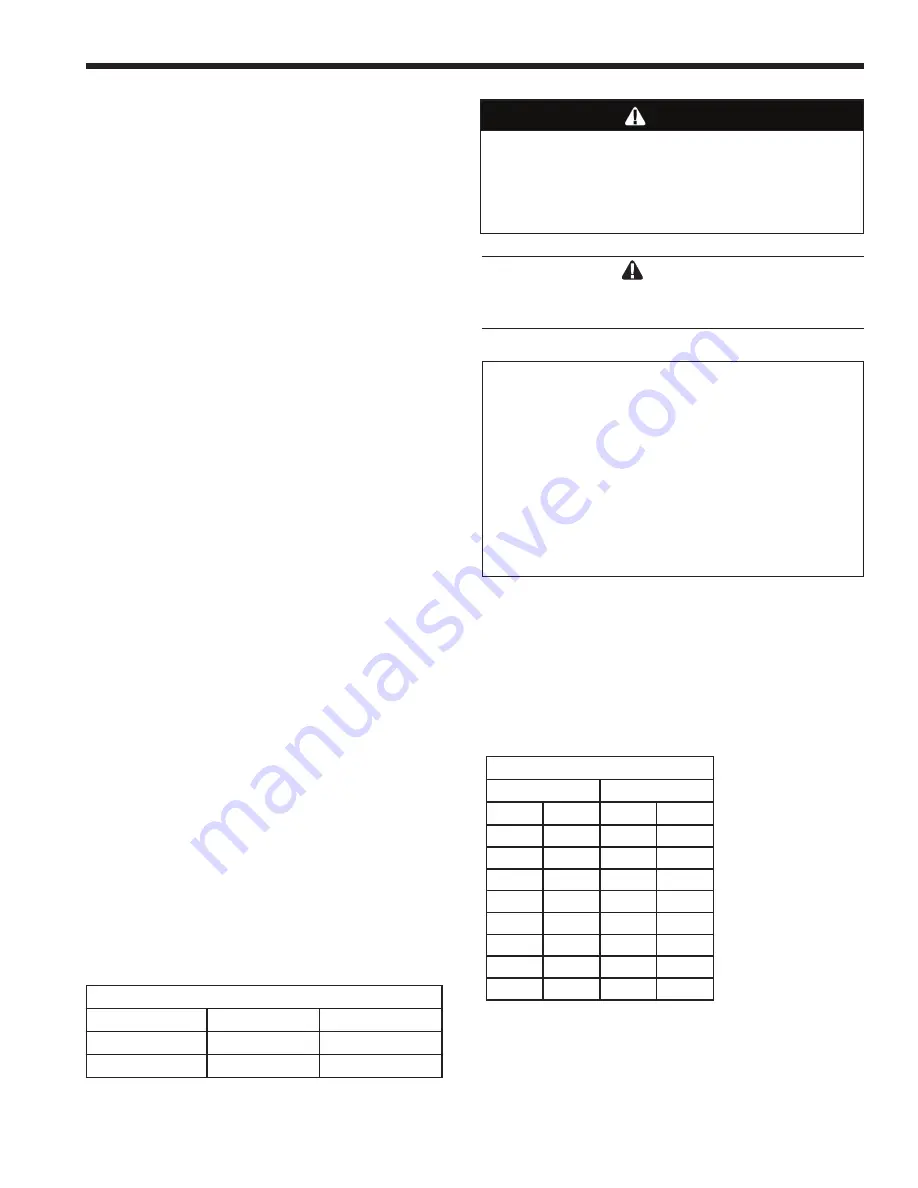

Inlet Gas Supply Pressure

Min”

Max

Natural Gas

3.5” W.C.

10.5” W.C.

Propane

8” W.C.

13” W.C.

Table 8.

Gas Pressure

Table 9.

To Size Your Gas Piping

Required

Propane

Natural Gas

Size

CU FT/

HR

Size

CU FT/

HR

150

60

150

150

199

80

199

199

285

114

285

285

399

160

399

399

500

200

500

500

600

240

600

600

750

300

750

750

850

340

850

850

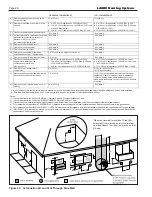

To size piping:

Measure linear distance from meter outlet to last boiler.

Add total input of all boilers and divide by 1000 to obtain

cu ft / hr required. Add total equivalent length of fittings

used according to Table 10 on page 32. Align total

length (pipe and fittings) on left side column of Table 11

on page 32 with highest cubic feet of gas required.

WARNING:

Open flame can cause gas to ignite and result in

property damage, severe injury, or loss of life.

N

EO

T

HERM

Commercial Boilers and Water Heaters

Summary of Contents for Neotherm NTH

Page 4: ...LAARS Heating Systems...

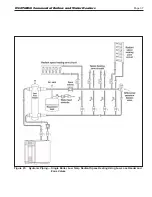

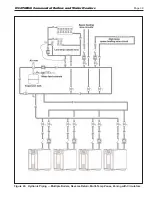

Page 36: ...Page 36 Figure 22 Hydronic Piping Single Boiler Zoning with Circulators LAARS Heating Systems...

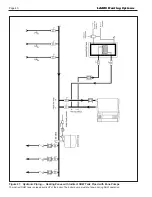

Page 52: ...Page 52 Figure 36 Ladder Diagram 7 H Ladder Diagram LAARS Heating Systems...

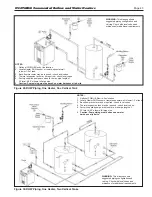

Page 100: ...Page 100 Parts Illustration 4 Internal Components Sizes 750 850 LAARS Heating Systems...

Page 102: ...Page 102 Parts Illustration 6 Gas Train Components Sizes 600 850 LAARS Heating Systems...