OC60-E2, OC95-E2, WSM

ENGINE

S-41

[3] SARVICING

(1) Clinder Head and Valves

Cylinder Head Surface Flatness

1. Thoroughly clean the cylinder head surface.

2. Place a straightedge on the cylinder head's four sides and two

diagonal as shown in the photo.

3. Measure the clearance with a thickness gauge.

4. If the measurement exceeds the allowable limit, correct it with

a surface grinder.

A

Do not place the straight edge on the combustion

chamber.

Cylinder Head Flaw

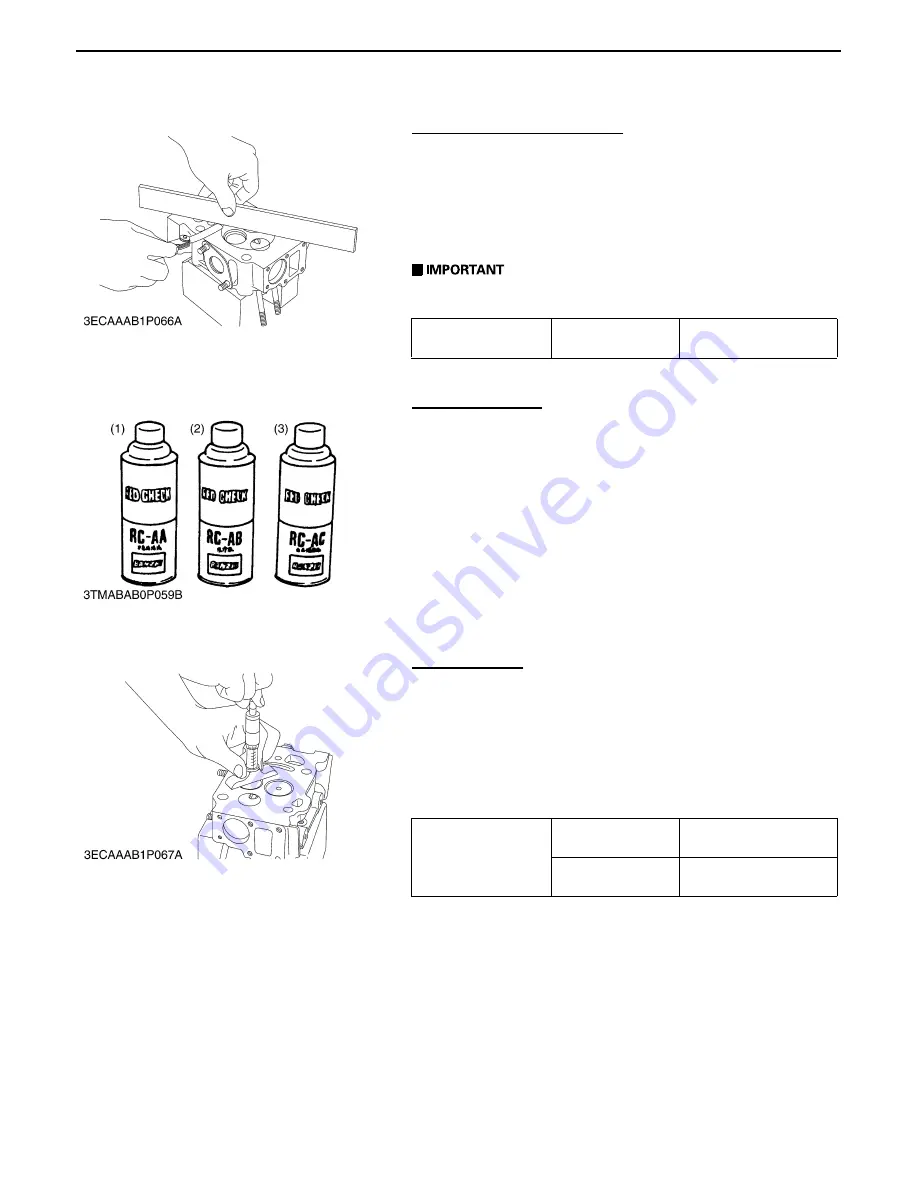

1. Prepare an air spray red check.

2. Clean the surface of the cylinder head with the detergent (2).

3. Spray the cylinder head surface with the red permeative liquid

(1). Leave it five to ten minutes after spraying.

4. Wash away the red permeative liquid on the cylinder head

surface with the detergent (2).

5. Spray the cylinder head surface with the white developer (3).

6. If flawed, it can be identified as red marks.

Valve Recessing

1. Clean the cylinder head, the valve face and seat.

2. Insert the valve into guide.

3. Measure the valve recessing with a depth gauge.

4. If the measurement exceeds the allowable limit replace the

valve.

5. If it still exceeds the allowable limit after replacing the valve,

replace the cylinder head.

Cylinder head surface

flatness

Allowable limit

0.05 mm

0.0020 in.

0000009255E

(1)

Red Permetive Liquid

(3)

White Developer

(2)

Detergent

00000007716E

Valve recessing

Factory spec.

0.60 to 0.85 mm

0.0236 to 0.0335 in.

Allowable limit

1.3 mm

0.0512 in.

0000009257E