SECTION 3 - TROUBLESHOOTING

3121804

– JLG Lift –

3-1

SECTION 3. TROUBLESHOOTING

3.1

GENERAL

This section contains troubleshooting information to be

used for locating and correcting most of the operating

problems which may develop in the aerial platform. If a

problem should develop which is not presented in this

section or which is not corrected by listed corrective

actions, technically qualified guidance should be obtained

before proceeding with any maintenance.

Troubleshooting and maintenance information pertaining

to the prime mover (engine/motor) that are not contained

in this manual are contained in the applicable engine

maintenance manual.

3.2

TROUBLESHOOTING INFORMATION

The troubleshooting procedures applicable to the aerial

platform are listed and defined in Tables 3-1 through 3-4.

As an aid to table use, the platform sizzor is divided into 4

major groups, each covered separately within this section.

These groups are as follows: Platform, chassis, hydraulic

system and electrical system.

Each malfunction within an individual group or system is

followed by a listing of probable causes which will enable

determination of the applicable remedial action. The prob-

able causes and remedial action should, where possible,

be checked in the order listed in the tables.

It should be noted that there is no substitute for a thor-

ough knowledge of the equipment and related systems.

It should be recognized that the majority of the problems

arising in the machine will be centered in the hydraulic

and electrical systems. For this reason, every effort has

been made to ensure that all likely problems in these

areas are given the fullest possible treatment. In the

remaining machine groups, only those problems which

have more than one probable cause and remedy are

included. This means that problems for which the proba-

ble cause and remedy may be immediately obvious are

not listed in this section.

The first rule for troubleshooting any circuit that is hydrau-

lically operated and electrically controlled is to determine

if the circuit is lacking hydraulic oil and electrical power.

This can be ascertained by overriding the bypass valve

(mechanically or electrically) so that oil is available to the

function valve, then overriding the function valve mechani-

cally. If the function performs satisfactorily, the problem

exists with the control circuit.

3.3

HYDRAULIC CIRCUIT CHECKS

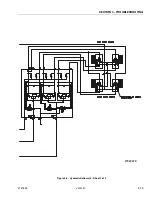

The first reference for improper function of a hydraulic sys-

tem, where the cause is not immediately apparent, should

be the troubleshooting chart. The best place to begin the

problem analysis is at the power source (pump) Once it is

determined that the pump is serviceable, then a system-

atic check of the circuit components, beginning with the

control, would follow. For aid in troubleshooting, refer to

the Illustrated Parts Manual for hydraulic diagram of the

various circuits.

Summary of Contents for 330CRT

Page 1: ...Service Maintenance Manual Model 330CRT 400CRT 3121804 April 7 2004 ...

Page 2: ......

Page 8: ...TABLE OF CONTENTS iv JLG Lift 3121804 This page left blank intentionally ...

Page 12: ...SECTION 1 SPECIFICATIONS 1 4 JLG Lift 3121804 Figure 1 1 Torque Chart ...

Page 22: ...SECTION 2 PROCEDURES 2 8 JLG Lift 3121804 Figure 2 3 400CRT LIft Cylinder ...

Page 54: ...SECTION 3 TROUBLESHOOTING 3 12 JLG Lift 3121804 Figure 3 3 Hydraulic Schematic Sheet 1 of 2 ...

Page 56: ...SECTION 3 TROUBLESHOOTING 3 14 JLG Lift 3121804 This page intentionally left blank ...

Page 57: ......