SECTION 2 - PROCEDURES

2-18

– JLG Lift –

3121804

2.15 LIMIT SWITCH ADJUSTMENT

Speed Cutout Switch

The speed cutout switch is located on the right side of the

frame of the machine. When activated, the switch cuts out

the high drive function. Adjust the switch to activate when

the platform is raised above the stowed position.

Drive Cutout Switch (400 CRT)

The drive cutout switch is located on the left side of the

frame of the machine. When activated, the switch cuts out

the drive function. Adjust the switch to activate when the

platform is raised to 9.1m (30 ft.).

2.16 AUTOMATIC CHOKE - FIELD

ADJUSTMENT (DF-750)

Inspection

NOTE: All automatic choke assemblies have been pre-set to

operate between -7°C and 38°C (20°F and 100°F)

with little or no adjustment. If the machine will be

operated for prolong use outside these temperature

ranges, adjustments could be made to improve per-

formance of the engine.

The machine will take time to warm up and you may

experience low power or rough running for the first

few minutes of operation or until the engine warms

up. LET THE ENGINE WARM UP.

Make sure that the choke shaft operates freely and does

not bind. This can be done without removing the air horn

by rotating the bronze coupling with an eraser on a pencil

or by removing the vacuum pull off line at the manifold

and supply a small amount of vacuum to the hose. the

choke rod should move freely using either method.

Adjustments

NOTE: If the choke rod is binding make sure the support

bracket is straight

1.

There are two adjustments Vertical (loosening the air

horn nuts) and Horizontal (loosening the bracket to

adaptor screws). These two adjustments should

resolve any binding problem.

2.

To adjust the choke at 21°C (70°F) ambient, remove

the air horn and reinstall the nut that holds the choke

and support bracket securely making sure the

choke moves freely.

3.

Loosen the 3 top cover screws and rotate the top

cover till the choke butterfly is closed with 1/32 in

space between the plate and the wall of the carbure-

tor.

4.

If the ambient temperature is less then 21°C (70°F)

the top cover counter should be rotated CCW 1

mark for every -15°C (5°F) less then 21°C (70°F).

5.

If the ambient temperature is more then 21°C (70°F)

the top cover counter should be rotated CW 1 mark

for every -15°C (5°F) less then 21°C (70°F).

.

Reassembly

Reassemble the air horn making sure the choke is not

binding, test to insure that none of the settings have

moved and the choke is not binding.

The vacuum pull off should be set such that when vacuum

is applied to the choke system the choke butterfly is full

open.

NOTE: If the machine starts and stalls immediately or if it is

extremely cold, limiting the choke pull off to 75% to

90% may improve the performance of the machine.

No adjustment is normally required.

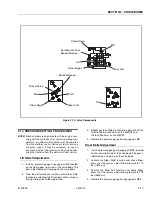

Figure 2-20. Automatic Choke Adjustment (DF-750)

Summary of Contents for 330CRT

Page 1: ...Service Maintenance Manual Model 330CRT 400CRT 3121804 April 7 2004 ...

Page 2: ......

Page 8: ...TABLE OF CONTENTS iv JLG Lift 3121804 This page left blank intentionally ...

Page 12: ...SECTION 1 SPECIFICATIONS 1 4 JLG Lift 3121804 Figure 1 1 Torque Chart ...

Page 22: ...SECTION 2 PROCEDURES 2 8 JLG Lift 3121804 Figure 2 3 400CRT LIft Cylinder ...

Page 54: ...SECTION 3 TROUBLESHOOTING 3 12 JLG Lift 3121804 Figure 3 3 Hydraulic Schematic Sheet 1 of 2 ...

Page 56: ...SECTION 3 TROUBLESHOOTING 3 14 JLG Lift 3121804 This page intentionally left blank ...

Page 57: ......