SECTION 2 - PROCEDURES

2-4

– JLG Lift –

3121804

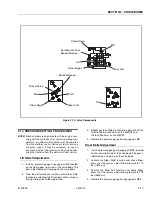

Proportional Control Valves

The proportional control valves provide a power output

matching that required by the load. A small line connected

to a load sensing port feeds load pressure back to a

sequence valve. The sequence valve senses the differ-

ence between the load and pump outlet pressure, and

varies the pump displacement to keep the difference con-

stant. This differential pressure is applied across the

valve’s meter-in spool, with the effect that pump flow is

determined by the degree of spool opening, independent

of load pressure. Return lines are connected together,

simplifying routing of return flow and to help reduce cavi-

tation. Load sensing lines connect through shuttle valves

to feed the highest load signal back to the sequence

valve. Integral actuator port relief valves, anti-cavitation

check valves, and load check valves are standard.

Relief Valves

Main relief valves are installed at various points within the

hydraulic system to protect associated systems and com-

ponents against excessive pressure. Excessive pressure

can be developed when a cylinder reaches its limit of

travel and the flow of pressurized fluid continues from the

system control. The relief valve provides an alternate path

for the continuing flow from the pump, thus preventing

rupture of the cylinder, hydraulic line or fitting. Complete

failure of the system pump is also avoided by relieving cir-

cuit pressure. The relief valve is installed in the circuit

between the pump outlet (pressure line) and the cylinder

of the circuit, generally as an integral part of the system

valve bank. Relief pressures are set slightly higher than

the load requirement, with the valve diverting excess

pump delivery back to the reservoir when operating pres-

sure of the component is reached.

Crossover Relief Valves

Crossover relief valves are used in circuits where the actu-

ator requires an operating pressure lower than that sup-

plied to the system. When the circuit is activated and the

required pressure at the actuator is developed, the cross-

over relief diverts excess pump flow to the reservoir. Indi-

vidual, integral reliefs are provided for each side of the

circuit.

2.6

COMPONENT FUNCTIONAL

DESCRIPTION

Hydraulic Pump

The machine is equipped with two hydraulic pumps, a

function pump and a drive pump. The function pump is a

single-section gear pump that controls the lift and steer

functions and provides a maximum output of 18 lpm (4.75

gpm). The drive pump is a single-section piston pump that

controls the drive function and provides an output of 83.3

lpm (22 gpm).

Lift Cylinder Counterbalance/Manual

Descent Valve

The lift cylinder counterbalance/manual descent valve is

located on top of the lift cylinder. The counterbalance

valve is used to hold the platform in place when raised. A

cable is connected to the valve which, when pulled, manu-

ally opens the lift down port and allows the platform to be

lowered in the event hydraulic power is lost.

2.7

WEAR PADS

Sliding Pads

The original thickness of the sliding pads is 51 mm (2 in).

Replace sliding pads when worn to 48 mm (1.875 in).

2.8

CYLINDER CHECKING PROCEDURES

NOTE: Cylinder checks must be performed any time a cylin-

der component is replaced or when improper system

operation is suspected.

Cylinder w/o Counterbalance Valves - Steer

Cylinder

IMPORTANT

OPERATE FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

DO NOT FU LLY EXTEN D CYLINDER TO END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRES-

SURE.

1.

Using all applicable safety precautions, activate

motor and fully extend cylinder to be checked. Shut

down motor.

2.

Carefully disconnect hydraulic hose from retract port

of cylinder. There will be initial weeping of hydraulic

fluid which can be caught in a suitable container.

After the initial discharge, there should be no further

leakage from the retract port.

Summary of Contents for 330CRT

Page 1: ...Service Maintenance Manual Model 330CRT 400CRT 3121804 April 7 2004 ...

Page 2: ......

Page 8: ...TABLE OF CONTENTS iv JLG Lift 3121804 This page left blank intentionally ...

Page 12: ...SECTION 1 SPECIFICATIONS 1 4 JLG Lift 3121804 Figure 1 1 Torque Chart ...

Page 22: ...SECTION 2 PROCEDURES 2 8 JLG Lift 3121804 Figure 2 3 400CRT LIft Cylinder ...

Page 54: ...SECTION 3 TROUBLESHOOTING 3 12 JLG Lift 3121804 Figure 3 3 Hydraulic Schematic Sheet 1 of 2 ...

Page 56: ...SECTION 3 TROUBLESHOOTING 3 14 JLG Lift 3121804 This page intentionally left blank ...

Page 57: ......