SECTION 2 - PROCEDURES

3121804

– JLG Lift –

2-15

IMPORTANT

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYL-

INDER ROD, SPACER, AND PISTON. AVOID PULLING THE ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

4.

With the barrel clamped securely, apply pressure to

the rod pulling device and carefully withdraw the

complete rod assembly from the cylinder barrel.

5.

Using a suitable chain wrench, carefully remove the

remaining cylinder head retainer from the opposite

end of the cylinder barrel. Remove the head and

remove and discard the wiper, rod seal, 0-ring and

wear ring.

6.

Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture.

7.

Carefully remove the head from the cylinder rod and

remove and discard the wiper, rod seal, o-ring and

wear ring.

8.

Carefully remove the spacers from the cylinder rod,

then remove the retaining rings securing the piston

in place on the cylinder rod. Discard the retaining

rings.

9.

Carefully remove the piston from the cylinder rod.

Remove and discard the T-seal and o-ring.

10.

Remove the cylinder rod from the holding fixture.

Cleaning and Inspection

1.

Clean all parts thoroughly in an approved cleaning

solvent.

2.

Inspect the cylinder rod for scoring, tapering, ovality,

or other damage. If necessary, dress the rod with

Scotch Brite or equivalent. Replace the rod if neces-

sary.

3.

Inspect the threaded portion of the rod for excessive

damage. Dress the threads as necessary.

4.

Inspect the inner surface of the cylinder barrel tube

for scoring or other damage. Check the inside diam-

eter for tapering or ovality. Replace the barrel if nec-

essary.

5.

Inspect the piston surface for damage, scoring and

distortion. Dress the piston surface or replace the

piston as necessary.

6.

Inspect the seal and o-ring grooves in the piston for

burrs and sharp edges. Dress applicable surfaces

as necessary.

7.

Inspect the inside diameter of the spacers and

heads for scoring or other damage and for ovality

and tapering. Replace as necessary.

8.

Inspect the seal and o-ring grooves in the heads for

burrs and sharp edges. Dress applicable surfaces

as necessary.

9.

Inspect the outside diameter of the spacers and

heads for scoring or other damage and ovality and

tapering. Replace as necessary.

10.

Inspect the oil ports for blockage or the presence of

dirt or other foreign material. Repair as necessary.

11.

Inspect the cam follower for wear or damage.

Replace as necessary.

Assembly

NOTE: Prior to cylinder assembly, ensure that the proper

cylinder seal kit is used.

Apply a light film of hydraulic oil to all components

prior to assembly.

1.

Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture.

2.

Place a new o-ring into the cylinder rod piston

groove.

3.

Place a new T-seal on the piston, then carefully

install the piston the cylinder rod, ensuring that the

o-ring in the rod groove is not damaged or dis-

lodged. Secure the piston in place with two new

retaining rings.

4.

Carefully slide the spacers onto the cylinder rod.

5.

Place a new wiper, rod seal, o-ring and wear ring on

each of the two cylinder heads. Set the heads aside

for later installation on the cylinder rod.

6.

Remove the cylinder rod assembly from the holding

fixture.

7.

Position the cylinder barrel in a suitable holding fix-

ture.

IMPORTANT

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE

CYLINDER ROD, PISTON AND HEADS. AVOID PULLING THE ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

8.

With the barrel clamped securely, and while ade-

quately supporting the cylinder rod assembly, insert

the cylinder rod assembly into the cylinder barrel.

Ensure that the piston T-seal and o-ring are not dam-

aged or dislodged.

9.

Continue pushing the rod assembly into the cylinder

barrel until the cylinder rod is approximately cen-

tered in the barrel.

Summary of Contents for 330CRT

Page 1: ...Service Maintenance Manual Model 330CRT 400CRT 3121804 April 7 2004 ...

Page 2: ......

Page 8: ...TABLE OF CONTENTS iv JLG Lift 3121804 This page left blank intentionally ...

Page 12: ...SECTION 1 SPECIFICATIONS 1 4 JLG Lift 3121804 Figure 1 1 Torque Chart ...

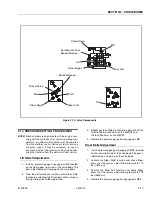

Page 22: ...SECTION 2 PROCEDURES 2 8 JLG Lift 3121804 Figure 2 3 400CRT LIft Cylinder ...

Page 54: ...SECTION 3 TROUBLESHOOTING 3 12 JLG Lift 3121804 Figure 3 3 Hydraulic Schematic Sheet 1 of 2 ...

Page 56: ...SECTION 3 TROUBLESHOOTING 3 14 JLG Lift 3121804 This page intentionally left blank ...

Page 57: ......