•

Helmet

•

Safety goggles, preferably with side shields

•

Protective shoes

•

Protective gloves

•

Gas mask

•

Hearing protection

•

First-aid kit

•

Safety devices

Electrical connections

Electrical connections must be made by certified electricians in compliance with all international, nation-

al, state, and local regulations. For more information about requirements, see sections dealing specifical-

ly with electrical connections.

1.2.3.1 Precautions before work

Observe these safety precautions before you work with the product or are in connection with the product:

•

Provide a suitable barrier around the work area, for example, a guard rail.

•

Make sure that all safety guards are in place and secure.

•

Make sure that the equipment is properly insulated when it operates at extreme temperatures.

•

Recognize the site emergency exits, eye wash stations, emergency showers and toilets.

•

Allow all system and pump components to cool before you handle them.

•

Make sure that you have a clear path of retreat.

•

Make sure that the product cannot roll or fall over and injure people or damage property.

•

Make sure that the lifting equipment is in good condition.

•

Use a lifting harness, a safety line, and a breathing device as required.

•

Make sure that the product is thoroughly clean.

•

Make sure that there are no poisonous gases within the work area.

•

Make sure that you have quick access to a first-aid kit.

•

Disconnect and lock out power before servicing.

•

Check the explosion risk before you weld or use electric hand tools.

1.2.3.2 Wash the skin and eyes

1.

Follow these procedures for chemicals or hazardous fluids that have come into contact with your

eyes or your skin:

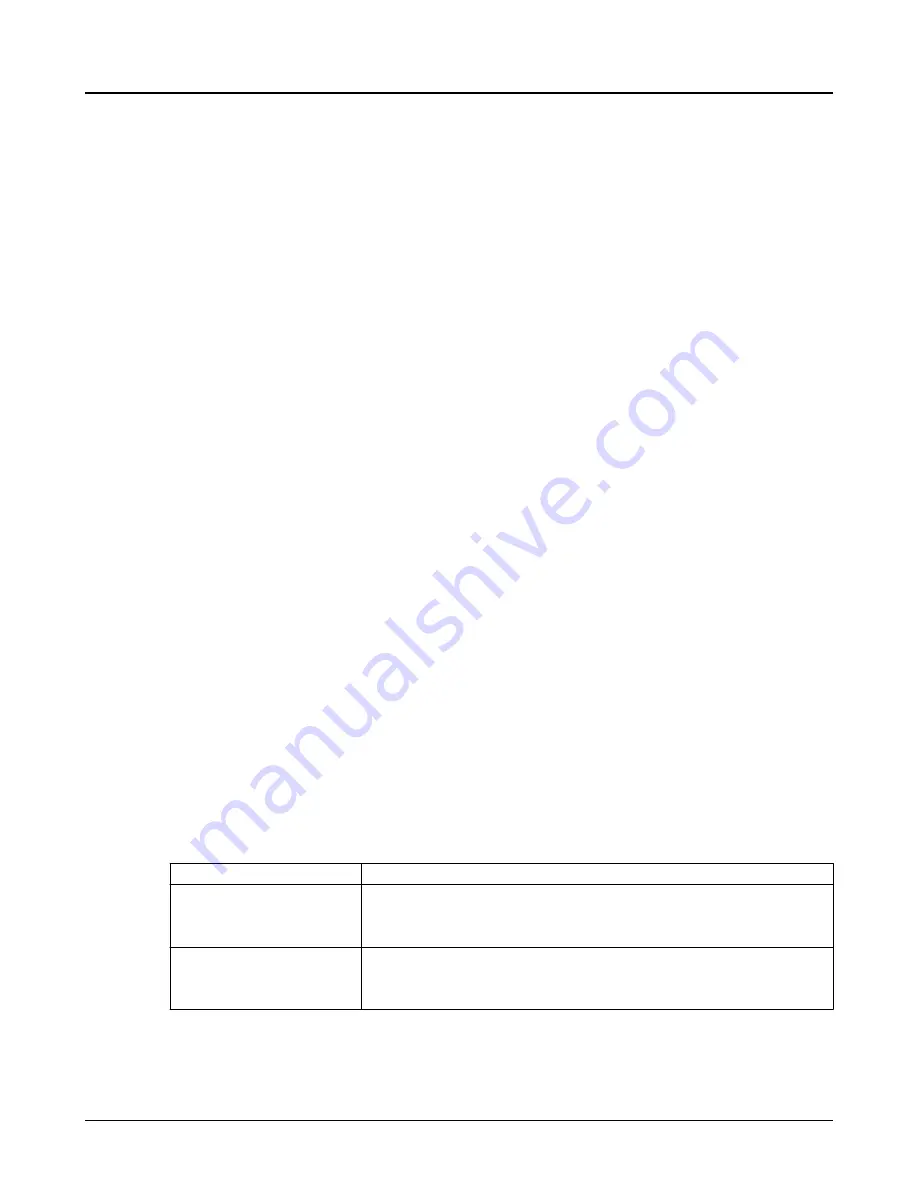

Condition

Action

Chemicals or hazardous fluids

in eyes

1.

Hold your eyelids apart forcibly with your fingers.

2.

Rinse the eyes with eyewash or running water for at least 15 minutes.

3.

Seek medical attention.

Chemicals or hazardous fluids

on skin

1.

Remove contaminated clothing.

2.

Wash the skin with soap and water for at least 1 minute.

3.

Seek medical attention, if necessary.

1.2 Safety

Model 3700, 3703, 3710, 3700LF, 3700LFI API Type OH2 / ISO 13709 1st and 2nd Ed. / API 610 8/9/10/11th Ed. Instal-

lation, Operation, and Maintenance Manual

7

Summary of Contents for Goulds Pumps 3700

Page 2: ......