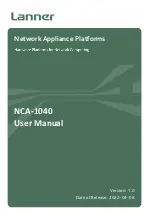

Heat Sink Back Plate Drawings

134

Thermal/Mechanical Specifications and Design Guidelines

§

Figure E-3. Reference Design ILM Back Plate

(1.8

)

3.25±

0.5

18

18

2X

5.5±

0.15

5X R

4±

1

4X MAX R

1.8

2X R

MAX1

4.3

30.91

2X 30.11

B

47.6±0.3

0.2

A

B

20.9±0.1

0.2

A

B

C

29.5±0.1

CHAMFER

X 45°

5±

0.15

2X R

4±

1

C

71.9±0.3

A

THIS DRAWING CONTAINS INTEL CORPORATION CONFIDENTIAL INFORMATION. IT IS DISCLOSED IN CONFIDENCE AND ITS CONTENTS MAY NOT BE DISCLOSED, REPRODUCED, DISPLAYED OR MODIFIED, WITHOUT THE PRIOR WRITTEN CONSENT OF INTEL CORPORATION.

REVISION HISTORY

ZONE

REV

DESCRIPTION

DATE

APPROVE

-

A

INITIAL RELEASE

8/17/07

D. CARTE

D3

B

UPDATED MATERIAL PROPERTIES NOTES

8/29/07

D. CARTE

G7

C

-002: ADDED CHAMFER

01/03/08

T.BYQUIS

D

-003: MODIFIED CAVITY DIMENSION,

MODIFIED TOLERANCES

06/16/08

CCB

E

UPDATED FINISH/PLATING SPEC.

1/29/09

DEPARTMENT

R

2200 MISSION COLLEGE BLVD P.O. BOX 58119 SANTA CLARA, CA 95052-8119

PST-TMI

TITLE

LGA115X ILM BACKPLATE

SIZE

DRAWING NUMBER

REV

A1

E20847

E

4

DO

NOT

SCALE

DRAWING

1

1

FINISH

MATERIAL

01/03/08

T.BYQUIST

DATE

APPROVED BY

12/18/07

B. DALE

12/27/07

R. AOKI

DATE

CHECKED BY

12/17/07

K. SHIMADA

DATE

DRAWN BY

12/17/07

R. AOKI

DATE

DESIGNED BY

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

ALL UNTOLERANCED LINEAR

DIMENSIONS ±0.5

ANGLES ±1

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTION

PART NUMBER

ITEM NO

QTY

ILM BACKPLATE

E20847-003

TOP

8

3

C.L. OF C

3

3X PIERCE AND TAP 6-32 UNC THRU HOLE MIN 3 THREAD

SCALE 2

NOTES:

1. THIS DRAWING TO BE USED IN CONJUNCTION WITH THE SUPPLIED 3D DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE. 2. UNLESS OTHERWISE NOTED, TOLERANCES ON DIMENSIONED FEATURES ARE AS IN TOLERANCE BLOCK.

3

CRITICAL TO FUNCTION (CTF).

4. MATERIAL:

A) TYPE: 1.8MM ±

0.05

3

, SK7, 1065, S50C OR CHSP60PC.

B) CRITICAL MECHANICAL PROPERTIES FOR EQUIVALENT MATERIAL SELECTION: TENSILE YEILD STRENGTH (ASTM D638) >= 489 MPa MODULUS OF ELASTICITY (ASTM D638) >= 190 GPa 5. FINISH: 5 MICRON MIN. ZINC PLUS CLEAR CHROMATE PER ASTM B 633 COLORLESS OR 2 MICRON MIN. ELECTROLYTIC NICKEL PLATING. PROCESS TEST: 48 HRS 85°

C/85% HUMIDITY WITH NO VISIBLE CORROSION.

6. REMOVE ALL BURRS OR SHARP EDGES AROUND PERIMETER OF PART. SHARPNESS OF EDGES SUBJECT TO HANDLING ARE REQUIRED TO MEET UL1439 TEST. 7. PART SHALL BE DEGREASED AND FREE OF OIL AND DIRT MARKS.

8

PUNCH DIRECTION.

0.15

A

B

C

0.1

A

0.2

Summary of Contents for 2ND GENERATION CORE PROCESSOR FAMILY DESKTOP - THERMAL MECHANICAL S AND DESIGN GUIDELINES 01-2011

Page 12: ...Introduction 12 Thermal Mechanical Specifications and Design Guidelines...

Page 36: ...Independent Loading Mechanism ILM 36 Thermal Mechanical Specifications and Design Guidelines...

Page 62: ...PECI Interface 62 Thermal Mechanical Specifications and Design Guidelines...

Page 88: ...ATX Reference Thermal Solution 88 Thermal Mechanical Specifications and Design Guidelines...

Page 102: ...Boxed Processor Specifications 102 Thermal Mechanical Specifications and Design Guidelines...

Page 120: ...Mechanical Drawings 120 Thermal Mechanical Specifications and Design Guidelines...

Page 126: ...Socket Mechanical Drawings 126 Thermal Mechanical Specifications and Design Guidelines...

Page 130: ...Package Mechanical Drawings 130 Thermal Mechanical Specifications and Design Guidelines...