11

NOTICE

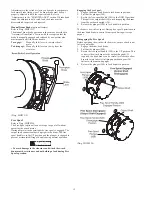

• Pendant haul-in and payout control buttons provide

variable speed operation. For low speed operation push

appropriate control button slightly; for full speed operation

push appropriate control button fully.

* To ensure accurate winch control when remotely operating the

winch at distances greater than 60 feet (18 metres) contact

Ingersoll-Rand Technical Sales for control suitability.

Emergency Stop Device (optional feature)

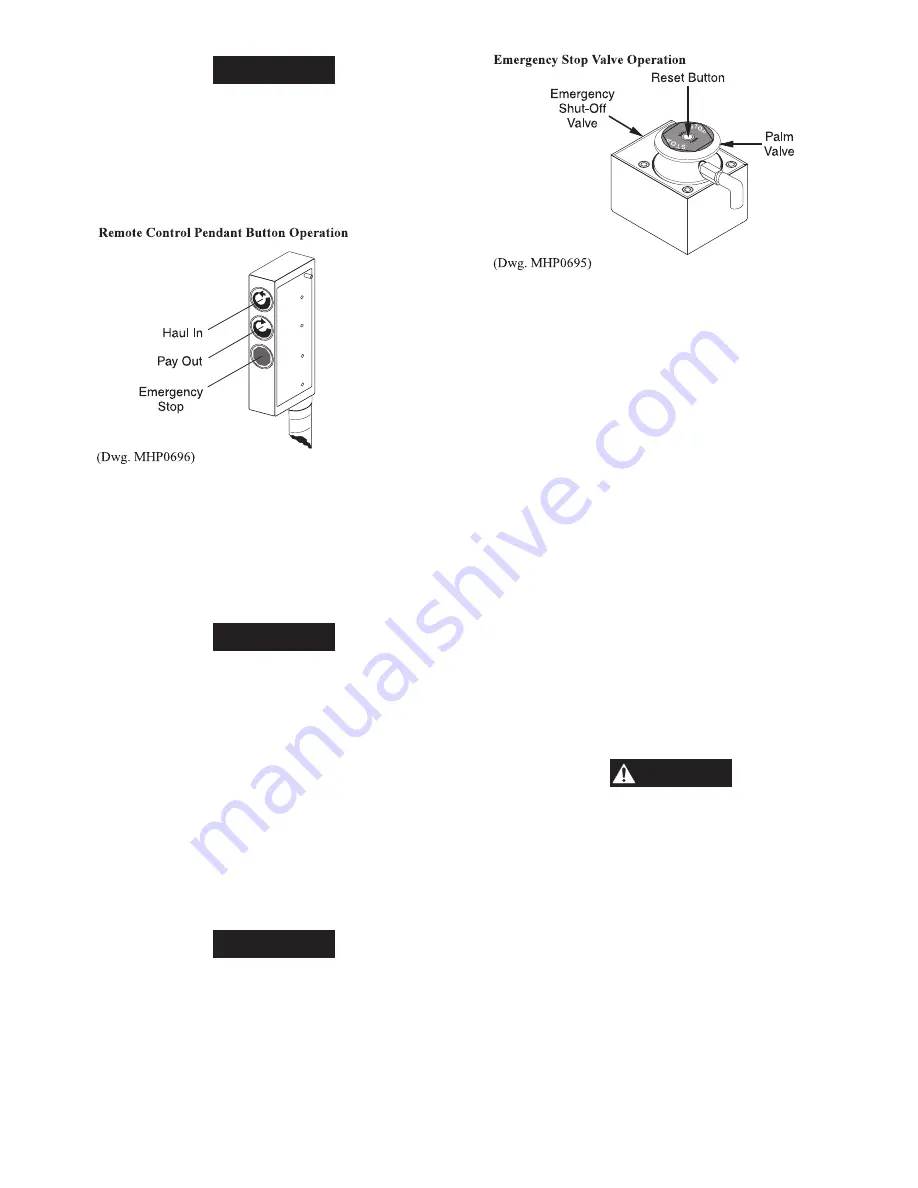

Refer to Dwg. MHP0695.

The emergency stop device is located at the air inlet of the

winch. When activated, winch drum rotation will immediately

cease. To activate the emergency stop valve conduct one of the

following:

1.

Depress (push down) red palm valve.

2.

Press emergency stop button on remote control pendant

(optional feature).

NOTICE

• The emergency stop is automatically engaged (blocks air

supply to winch) when winch air pressure is lost. If winch air

supply is lost the emergency stop must be reset, after air

supply is provided, before resuming winch operation. Refer

to ‘To Reset Emergency Stop Valve’ section.

If winch overload occurs the overload device, if equipped, also

stops the winch by activating the emergency stop device.

To Reset Emergency Stop Valve:

Refer to Dwg. MHP0695.

1.

Ensure air supply is available.

2.

Lift (pull up) red palm valve to full travel and hold for 2

seconds.

3.

Using a small tip screwdriver or similar tool, carefully

depress (push down) reset button to full travel. Reset button

is located in the center of the palm valve.

NOTICE

• If the Emergency Stop Valve will not reset inspect the

control valve for excessive internal air leakage.

Overload Device (optional feature)

An overload device is available on winches provided with the

emergency shut-off valve. Overload device operation is based on

the differential pressure between the motor inlet and exhaust.

The overload device is factory preset to actuate at 150% (+/-

25%) of rated capacity of the winch. When an overload

condition is sensed air is directed to the emergency shut-off

valve to isolate air to the winch.

If the overload device is activated the load must be reduced.

Reset the Emergency Stop Valve and operate the winch in the

payout direction to lower the load.

Winch Brakes

Automatic Disc Brake

The automatic disc brake is a spring applied, air released brake.

When the winch is operated in the payout direction air pressure

acting on the diaphragm overcomes spring pressure and releases

the brake. The brake automatically engages when winch

operation is returned from the payout direction to neutral or

when shifted to the haul-in direction. When the winch is in the

neutral or haul-in positions the brake air is vented and the brake

springs reapply the brake. The springs, acting on the pressure

plate, compress the brake friction and separator plates and

engage the brake to prevent drum rotation in the payout

direction.

The cam type sprag clutch assembly allows drum rotation in the

haul-in direction with the brake plates engaged, but prevents the

drum from rotating in the payout direction.

Disc brake adjustment is not required. If the disc brake does not

operate properly it must be disassembled, inspected and

repaired.

WARNING

• If the brake is disassembled, the friction and separator

plates must be correctly installed as shown in the

“MAINTENANCE” Adjustments section of this manual.

Failure to correctly install the friction and separator plates

can cause injury and/or property damage.

Automatic Drum Brake

The automatic drum brake is a spring applied, air released,

externally mounted brake which uses an air actuated, spring

loaded cylinder to automatically disengage the brake when the

motor is operated in either the haul-in or payout directions. Air

pressure directed to the cylinder overcomes spring pressure to

release the brake and allow the drum to rotate.

When the control valve is placed in the neutral position, the air

in the cylinder is vented allowing spring tension to automatically

engage the brake and prevent drum rotation.

Summary of Contents for force5 FA5A-LAK1

Page 34: ...34 WINCH ASSEMBLY PARTS DRAWING ...

Page 36: ...36 MOTOR ASSEMBLY PARTS DRAWING ...

Page 38: ...38 DISC BRAKE ASSEMBLY PARTS DRAWING ...

Page 40: ...40 DRUM BAND BRAKE ASSEMBLY PARTS DRAWING ...

Page 42: ...42 LEVER OPERATED CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 44: ...44 PENDANT OPERATED PILOT CONTROL VALVE ASSEMBLY PARTS DRAWING ...

Page 48: ...48 SHUTTLE VALVE ASSEMBLY PARTS DRAWING ...

Page 50: ...50 EMERGENCY STOP AND OVERLOAD ASSEMBLY PARTS DRAWING ...

Page 52: ...52 OPEN FRAME FACE WINCH ASSEMBLY PARTS DRAWING ...

Page 57: ...57 WINCH LABEL TAG LOCATION AND PART NUMBER REFERENCE DRAWING ...