29

XtrapulsCD1-a

Chapter 4 - Connections

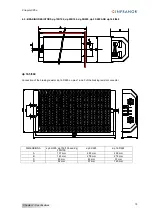

2 - WIRING

(according to EN61000.4-2-3-4-5 and EN55011 standards - see diagram "Shield connection on the connectors "

–

chapter 4, section 2.2).

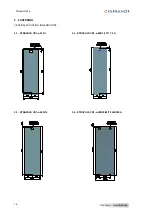

2.1 - GROUND WIRING AND LEAKAGE CURRENT

CAUTION !

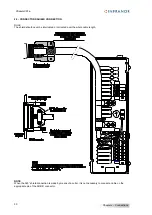

Each potential conducting element must be shielded. Several potential conductors in the same sleeve

must be twisted and shielded.

A shield has no effect if it is not connected:

-

to a reference potential,

-

by a connection as short as possible (a few centimeters; 10 centimeters are prohibited),

-

by a "360°" shield connection. This means that the whole circumference of the shield sleeve must be

connected to the reference conductor via a metal collar.

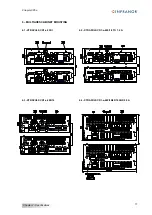

The connectors used for the compliance with the EN61000.4 standard must be made of metal or metallized and

must allow the 360° shield connections.

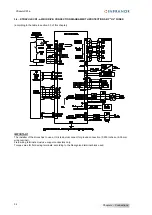

Reference potential loops (especially with the ground) are recommended

only

if these loops have a very low

impedance (< 0.1

). Any shield that is not used as a conductor can be connected at both ends under the

condition to be connected over 360° at both ends by means of metal links in order to ensure the shield continuity.

The preferred reference potential must be the earth.

Cables with low potential should

never

run in the proximity of power lines.

If there is a potential reference, i.e. a main chassis or cabinet with low impedance between its various elements, it

should be used for short connections to it and also be grounded itself.

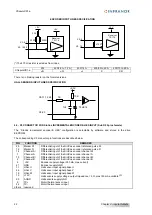

LEAKAGE CURRENT TO THE GROUND

The "Electronic Power Unit" equipment which includes the control, the drive, the motor and the

sensors, generates a leakage current to the ground higher than 30 mA continuous: the protection

conductor section must be

at least

10 mm² (Cu) or 16 mm² (Al).

This product may generate a leakage current with a DC component.

If a Residual Current Device is used, it should be:

- type A in single-phase applications,

- type B in three-phase applications.

The use of a 300 mA trip current is recommended.