6

Chapter 1

– General description

XtrapulsCD1-a

Chapter 1 - General description

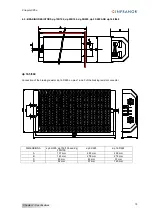

1- INTRODUCTION

Series

XtrapulsCD1-a

all-digital servo modules are PWM servo drives that provide speed control for AC

sinusoidal motors (brushless) equipped with a position sensor.

The

XtrapulsCD1-a

system is available as a stand-alone single-axis block including all supplies as well as the

mains filters, and is 230 VAC or 400/480 VAC mains operated.

2 - DESCRIPTION / COMPLIANCE WITH THE STANDARDS

2.1 - GENERAL DESCRIPTION

The

XtrapulsCD1-a

drive directly controls the motor torque and speed by means of the information provided by a

high resolution position sensor (resolver or encoder). The sinusoidal current commutation based on this high

resolution position sensor provides very smooth motor torque/force control.

The

XtrapulsCD1-a

drive can be configured for the feedback of various position sensor types. The appropriate

position sensor configuration is selectable by software and saved in the drive.

- With a resolver sensor feedback, the motor absolute position value over one revolution is available and the

servomotor can immediately be enabled after the drive power up.

- With a "SinCos tracks" sensor which provides two analog Sin and Cos signals electrically compatible with the

SinCos encoder signals and which period is equal to the motor pole pitch, the servo-motor can be immediately

enabled after the powering of the drive.

- With an absolute single-turn SinCos encoder feedback (Heidenhain ERN 1085 or compliant), the servo

motor can also immediately be enabled after the drive power up.

- With an incremental encoder only, a motor phasing procedure must be executed at each drive power up

before the motor enabling.

- With an incremental e Hall Effect Sensors (HES) feedback, the motor phasing procedure is no more

necessary and the servo motor can immediately be enabled after the drive power up.

- With an absolute single-turn, muti-turn or linear encoder using the ENDAT® or HIPERFACE® communication

protocols and fitted with incremental SinCos outputs, the servo-motor can also be immediately enabled after the

powering of the drive.

The motor speed or torque input command is an analog voltage (± 10 V). The rotor position monitor is available as

two channels A and B in quadrature, and one marker pulse per revolution.

The resolution is programmable. All the values between 64 pulses per revolution and 16384 pulses per revolution

(ppr) can be programmed according to the motor speed limitation. The main errors are displayed on the drive front

panel.

All command parameters are programmable by means of a serial RS-232 link (or RS-422 optional) and saved in

an EEPROM. The auto-phasing and auto-tuning functions allow the easy and quick commissioning of the drive.

The

XtrapulsCD1-a

drives have their own DC/DC converter to provide appropriate logic voltage to the modules.

An auxiliary 24V

DC

+/- 15 % supply is generally available on all machines and supplies a DC/DC converter with all

logic supplies required by the drive. The auxiliary supply keeps the drive logic supplies, after the power supply has

been switched off, in order to keep the position output without initializing the machine all over again. A 24

V

DC

battery supply with specific wiring keeps the position even after switching off the auxiliary 24 V

DC

supply.

This wiring can be used for "absolute" operation with the XtrapulsCD1-a drive (see chapter 4: Connections).