21

XtrapulsCD1-a

Chapter 3

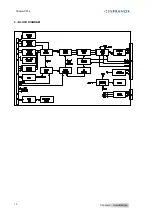

– Inputs-Outputs

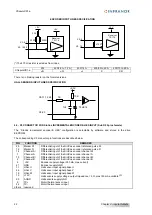

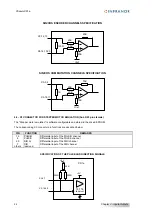

3.4 - SPECIFICATION OF THE ENCODER OUTPUTS

Recommended receiver: 26LS32

3.5 - SPECIFICATION OF THE ANALOG OUTPUT

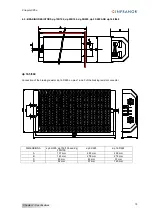

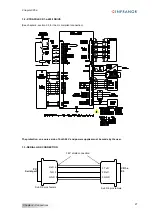

4 - X3 ENCODER INPUT

Same connector for both 230 V and 400 V ranges.

4.1 - X3 CONNECTOR FOR TTL INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins female)

The “TTL incremental encoder & HES” configuration is selectable by software and stored into the drive EEPROM.

The corresponding X3 connector pin functions are described below.

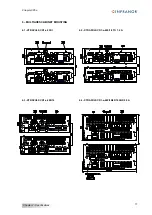

PIN

FUNCTION

REMARKS

18

Marker Z/

Differential input of the encoder marker pulse Z/

5

Marker Z

Differential input of the encoder marker pulse Z

19

Channel A/

Differential input of the encoder channel A/

6

Channel A

Differential input of the encoder channel A

20

Channel B/

Differential input of the encoder channel B/

7

Channel B

Differential input of the encoder channel B

8

+5 V

Encoder supply voltage

(300 mA max. current)

21

GND

Encoder supply GND

11

HALL U

Hall sensor input signal phase U

24

HALL V

Hall sensor input signal phase V

12

HALL W

Hall sensor input signal phase W

10

+12 V

Hall sensors supply voltage: output impedance = 9 Ω, max 150 mA available

(1)

23

AGND

Hall sensors supply GND

9

TC+

Motor thermal sensor input

22

TC-

Motor thermal sensor input

others

reserved

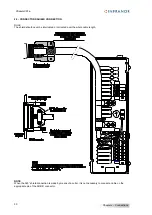

(1): The sum of the currents consumed by both X2 connector, pin 21, and X3 connector, pin 10,must not exceed

150 mA.

X2/11

X2/25

33K

200K

4.7nF