IO-Link master

58

35.8 Identification and maintenance

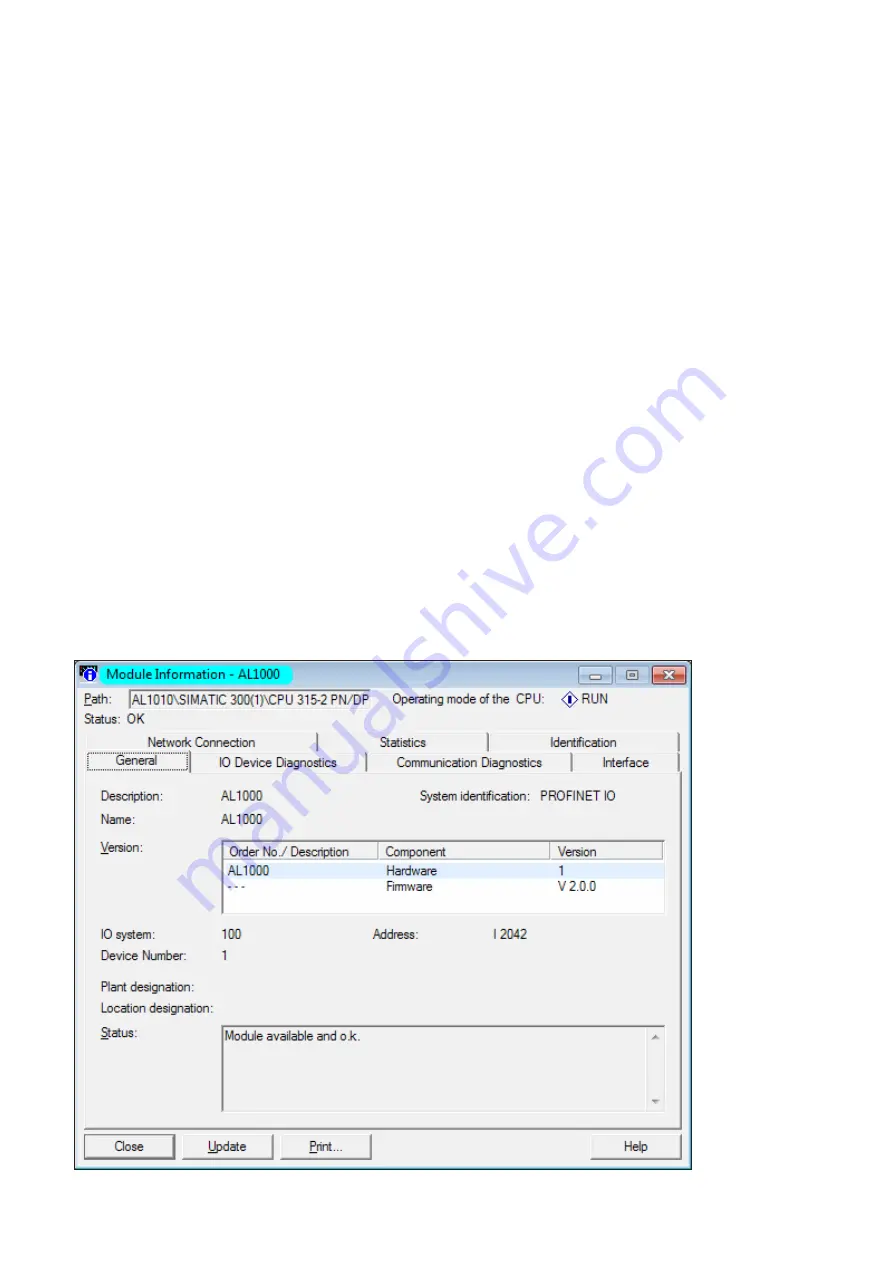

The identification and maintenance (I&M) data records are split over several STEP

7 dialogue boxes� An online connection to the device is required to display the I&M

data records�

The following steps must be carried out:

Switch the hardware manager to online view�

► Right-click on the module, then select [Module Information]�

► In the [General] tab, the order number / description, hardware version and

firmware version are listed in the [Version] area�

In the [Identification] tab, the module revision counter is listed in the [Module

information] area and the vendor ID (manufacturer's description), serial number,

profile, and profile details are listed in the [Manufacturer information] area�

I&M data records 1 - 3 can be read and written using the [Download/Upload

Module Identification] dialogue boxes�

The following steps must be carried out (offline view):

► Select the device�

► Select [Target system, Download module identification]�

► In the dialogue box you can now adapt the I&M data records (1 - 3) and write

them to the device with [OK]�