HANDLING AND INSTALLATION

4

- 22 -

3

02.

0

2

8

4.5.3

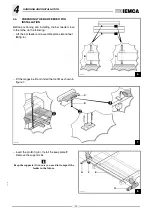

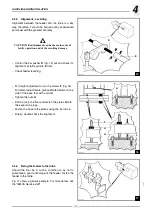

Alignment - Levelling

Alignment between the feeder and the lathe is a key

step, therefore, it should be carried out by experienced

personnel with the greatest accuracy.

CAUTION: Bad alignment can be the main cause of

faulty operation and of the resulting damage.

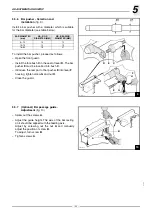

– Control the bar pusher

(fig. 15) out and check its

alignment at lathe spindle

E

inlet.

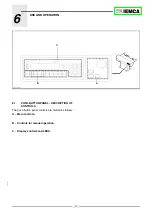

– Check feeder levelling.

– For height adjustments, turn the screws

(fig. 16).

For lateral adjustments, give calibrated blows on the

side of the base foot with a mallet.

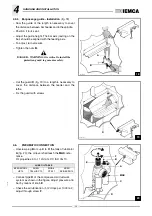

– Tighten the nuts

G

.

– Drill a hole in the floor and fasten the plates

H

with

the expansion plugs.

– Fasten the base to the plates using the tie rods

L

.

– Finally, double-check the alignment.

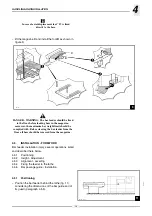

4.5.4

Fixing the feeder to the lathe

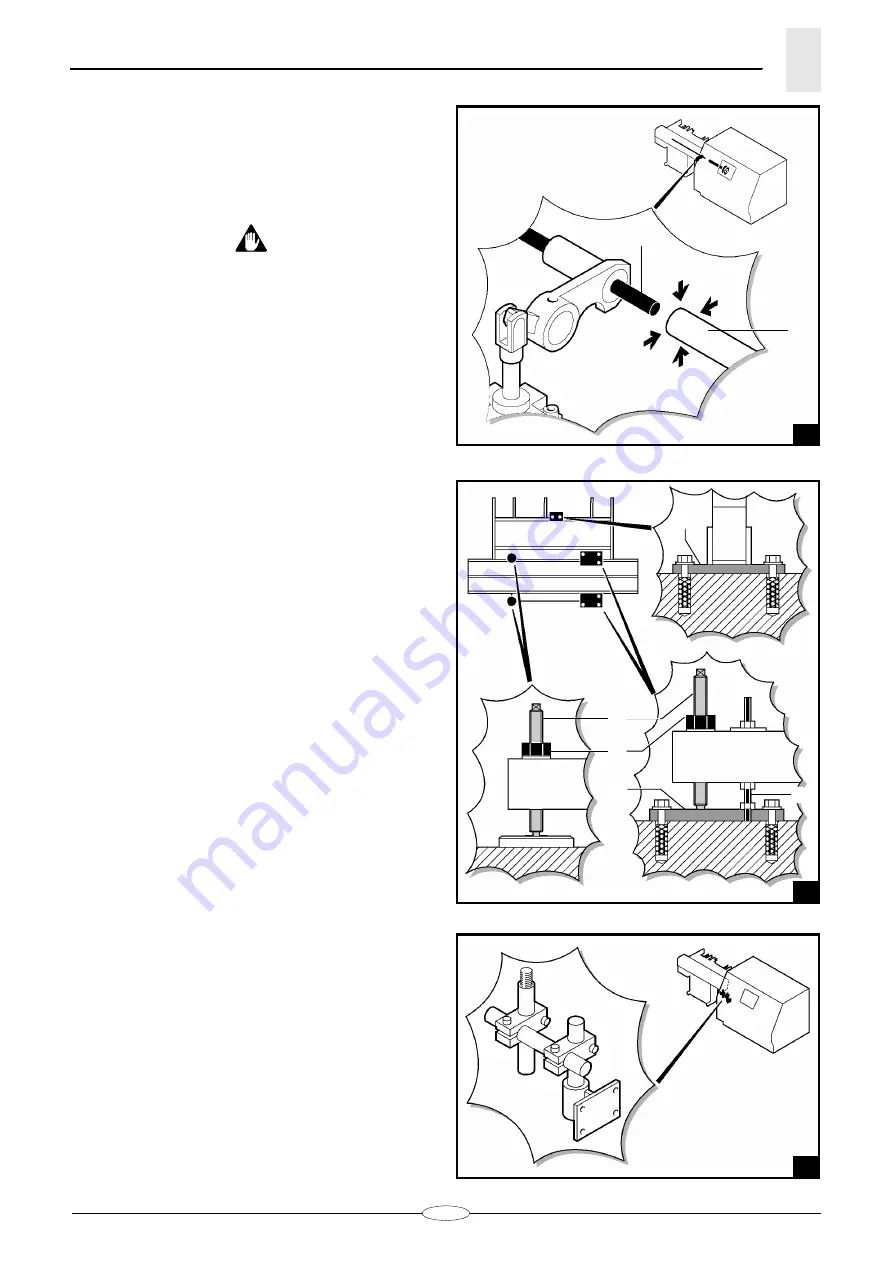

Should the floor be in such a condition so as not to

guarantee a good anchorage of the feeder, fasten the

feeder to the lathe.

Fig. 17 shows a generic example. For more details, ask

the "IEMCA Service staff".

28.029 Ec.2

D

E

•

28.030 Ec.0

H

F

G

H

L

28.033 Ec.0

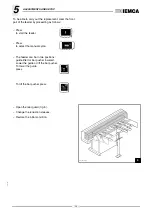

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

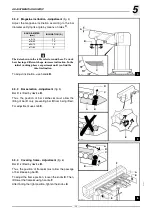

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......