44

2

INSTALLATION PROCEDURE

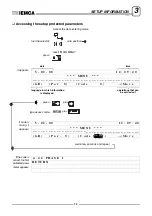

302.061

ERROR

CAUSE

SOLUTION

The safety devices of the lathe are

disabled.

The interface from lathe signal,

which stops the bar feeder, is

absent.

Check the “SAFETY FROM LATHE”

interface signal.

Check the lathe safety devices.

ERROR

CAUSE

SOLUTION

The bar feeder stopped and the K1,

K2 LED of the K35 safety unit is

also switched off.

An emergency stop push-button has

been pressed.

Check the status of the emergency

stop push-button.

An emergency signal from the lathe

is active.

Check if the sequence of signals

from the lathe is continuous: All the

signals must either be open or clo-

sed.

One of the covers of lathe or bar fee-

der is open.

Check that all covers are closed.

ERROR

CAUSE

SOLUTION

The bar feeder stopped or does not

start.

No air.

Check the pressure switch and the

air system pressure.

17

E r r o r : s a f e t y

f r o m

l a t h e

18

E r r o r : b a r

f e e d e r

e m e r g e n c y

E r r o r : a i r

p r e s s u r e

s w i t c h

19

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......