48

2

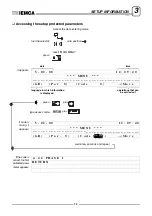

INSTALLATION PROCEDURE

302.061

ERROR

CAUSE

SOLUTION

The bar feeder has stopped due to

a fault.

Examples: Wrong bar-pusher move-

ment, bar not loaded in collet, bar

remnant missing, bar missing, etc..

Correct fault and reset with STOP

push-button.

ERROR

CAUSE

SOLUTION

The bar feeder is not locked but is

running.

The axial displacement device is not

locked.

Lock the axial displacement device.

The sensor is not providing the OK

signal.

Check that the sensor issues the

signal when the axial displacement

device is locked.

Check the correct operation of the

sensor.

ERROR

CAUSE

CURE

After the

key has been

pressed on the bar feeder keybo-

ard, this message appears.

The “MANUAL” mode was actuated

from the remote control panel on the

lathe.

Move the selector switch of the

remote control panel to the “AUTO-

MATIC” position.

28

R e s e t

w i t h

S T O P ! ! !

29

E r r o r : a x i a l

d i s p l a c e m e n t

n o t

l o c k e d

30

( E r r o r : . . . )

31

E r r o r : M a n u a l

f r o m

c o n t r o l

p a n e l

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......