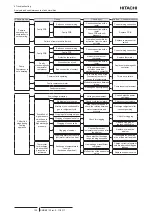

4 Troubleshooting

Analysis and countermeasure of abnormalities

SMGB0120 rev.0 - 11/2017

124

Phenomenon

Cause

Check Item

Action · Countermeasure

Chiller unit

stops during

heating

operation

Activation

of high

pressure

switch

due to

excessively

high

discharge

pressure

Mixture of non-condensable gas in

refrigerant cycle

Stop the chiller unit

and check the relation

between water

temperature and

pressure

Recharge refrigerant after

vacuum pumping

Clogging of pipes at discharge side

Check for clogging

Remove clogging

Clogging of expansion valve

Clogging of check valve

Remove clogging, or replace

check valve

Clogging of strainer

Check difference of

temperature before and

after the strainer

Replace or wash the strainer

Formation of lime deposit inside

heat exchanger

Check for dirt inside heat

exchanger

Clean heat exchanger

High temperature of the hot water

inlet at the heat exchanger

Check whether the usage

range is being exceeded

This is not a failure

Discharge

gas over-

increase is

activated

Suction gas temperature is too

high (excessive super heat)

Gas leakage or

insufficient refrigerant

Charge correct refrigerant

volume after checking gas

leakage

Malfunction of check

valve

Replace check valve

Clogging of expansion

valve

Remove clogging

Malfunction of the

expansion valve

Replace expansion valve

Failure of thermistor for control of

discharge gas

Check connection with

a tester

Replace thermistor for control

of discharge gas

Activation of

overcurrent

protection

control for

compressor

Activation of

compressor

internal

thermo

Excessive compressor operating

current

Power supply voltage too

high or too low

Set voltage during operation to

rated voltage

Phase unbalance in

power supply voltage

Measure voltage between each

phase, and consult with the

power company

Discharge pressure too

high

Investigation to determine the

cause

Single phase operation

Power source fuse blown

Replace power source fuse

Loosening of terminal-

type screws of power

source

Retighten screws

Rough contact of

electromagnetic contactor

of compressor motor

Replace contact

Faulty compressor bearing

It becomes locked

Compressor replacement

Insulation failure of compressor

motor

Measure insulation

resistance

Activation of

overcurrent

relay for

pump

Pump locked

Check frozen water,

clogging by foreign

bodies, etc.

Remove

Inappropriate RC value of

overcurrent relay for pump

Check RC value and

pump operating current

Change RC value or replace

electromagnetic switch

Faulty overcurrent relay for pump

Press reset button.

Check running current

Replace electromagnetic switch